Large-formwork casting construction method for transformer station accident oil pool

A technology of accident oil pool and construction method, which is applied in the direction of formwork/formwork/work frame, connection parts of formwork/formwork/work frame, construction, etc., and can solve the problem of affecting the integrity and strength of the oil pool and affecting the strength of the oil pool , surface unevenness and other problems, to achieve the effect of simple installation, easy disassembly and transportation, and improved surface flatness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] Below in conjunction with accompanying drawing, the present invention is described in further detail:

[0031] The large formwork pouring construction method of the substation accident oil pool is characterized in that it includes the following steps,

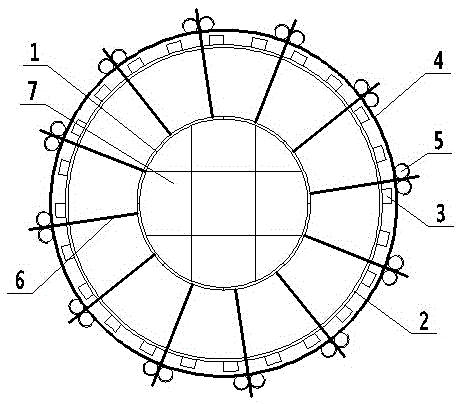

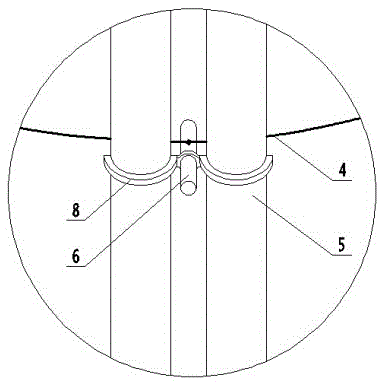

[0032] A. Positioning and mold matching, select the appropriate template according to the size of the accident oil pool, determine the center of the accident oil pool, the position of the outer mold and the position of the inner mold; the centers of the outer mold 2 and the inner mold 1 are the center of the oil pool, and the outer mold 2 rings are set outside the inner mold 1.

[0033] B. Set the guide wall, set the circular inner mold guide wall at the inner mold position, and set the circular outer mold guide wall at the outer mold position; the inner mold guide wall and the outer mold guide wall are concentric, and the inner mold guide wall is set on the inner mold Inside the guide wall; the height of the guide wall...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com