Sealing device with both fireproof and waterproof properties and its production process

A sealing device and performance technology, applied in the direction of pipes/pipe joints/fittings, mechanical equipment, pipe components, etc., can solve the urgent needs of urban modernization development, cannot adapt to the thermal expansion and contraction of cables, and can not achieve fire protection. Effectiveness and other issues, to achieve the effect of reducing system maintenance costs, breaking through technical bottlenecks, and convenient installation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The present invention will be further described in detail below in conjunction with the accompanying drawings and examples. The following examples are explanations of the present invention and the present invention is not limited to the following examples.

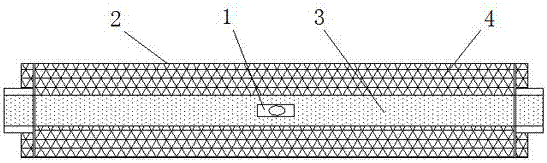

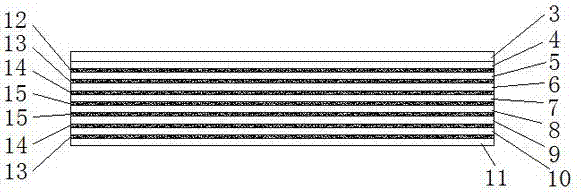

[0028] see Figure 1-Figure 2 , this embodiment includes an air intake device 1 and a bag body 2 with a sealed cavity inside. The bag body 2 sequentially includes a waterproof rubber strip 3, an alkali-free glass fiber layer 4, a high-temperature heat-sealing layer 5, a first puncture-resistant reinforcement layer 6, The first puncture-resistant layer 7 , the soft metal layer 8 , the second puncture-resistant layer 9 , the second puncture-resistant reinforced layer 10 and the low-temperature heat-sealing layer 11 .

[0029] In this embodiment, the alkali-free glass fiber layer 4 and the high-temperature heat-sealing layer 5 are bonded by a high-temperature, high-pressure strong adhesive layer 12 .

[0030] In this ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com