Reaction kinetics detecting device of dehydrogenation and catalyzation board and realizing method thereof

A technology of reaction kinetics and hydrogen elimination catalytic plate, which is applied in the direction of chemical analysis using catalysis, can solve the problems of large reaction fluctuations, fast reaction speed, complex influencing factors, etc., and achieve the effect that is difficult to measure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0056] The present invention will be further described below with reference to the accompanying drawings and embodiments, and the mode of the present invention includes but not limited to the following embodiments.

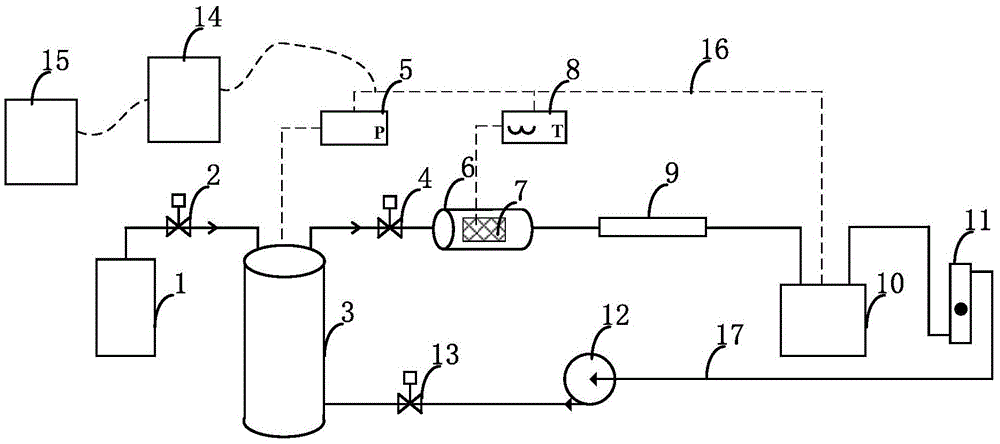

[0057] Such as figure 1 As shown, a device that can be used for the measurement of kinetic parameters of hydrogen elimination catalytic reaction includes a hydrogen source 1, a gas distribution tank 3, a reaction vessel 6, a drying tube 9, a hydrogen concentration meter 10, a flow meter 11, and a gas circulation pump 12 , data acquisition and processing device, connecting pipe 17 and each import and export valve.

[0058] The gas circulation pump 12, the gas distribution tank 3, the reaction vessel 6, the drying pipe 9, the hydrogen concentration meter 10 and the flow meter 11 are connected through a connecting pipe 17 to form a closed loop (also called a reaction loop in this embodiment).

[0059] The hydrogen source 1 is connected to the gas distribution tank 3...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com