Connector testing socket and connector testing device

A technology for testing sockets and connectors, applied in the direction of the housing of the measuring device, etc., can solve the problems of no connector testing device, inability to quickly test the correct installation of connecting terminals, affecting the normal use of connectors, etc., to achieve the effect of convenient replacement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The present invention is further described below in conjunction with embodiment and accompanying drawing.

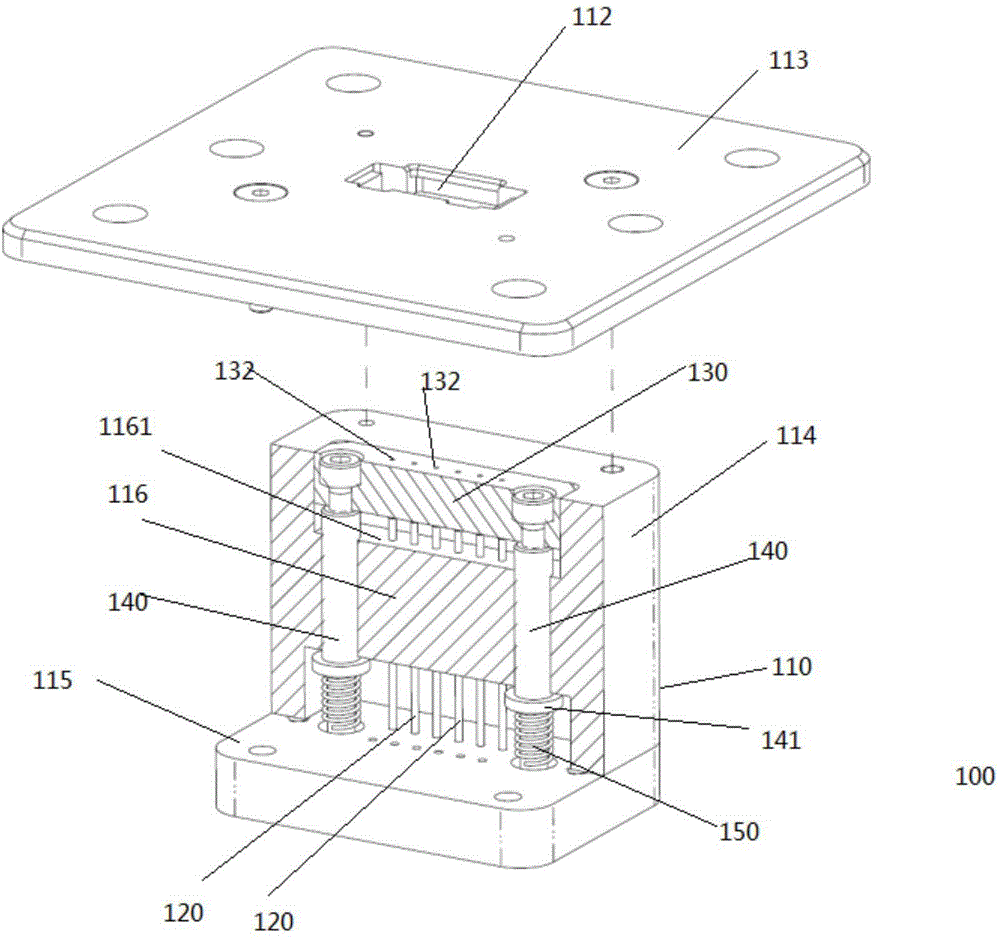

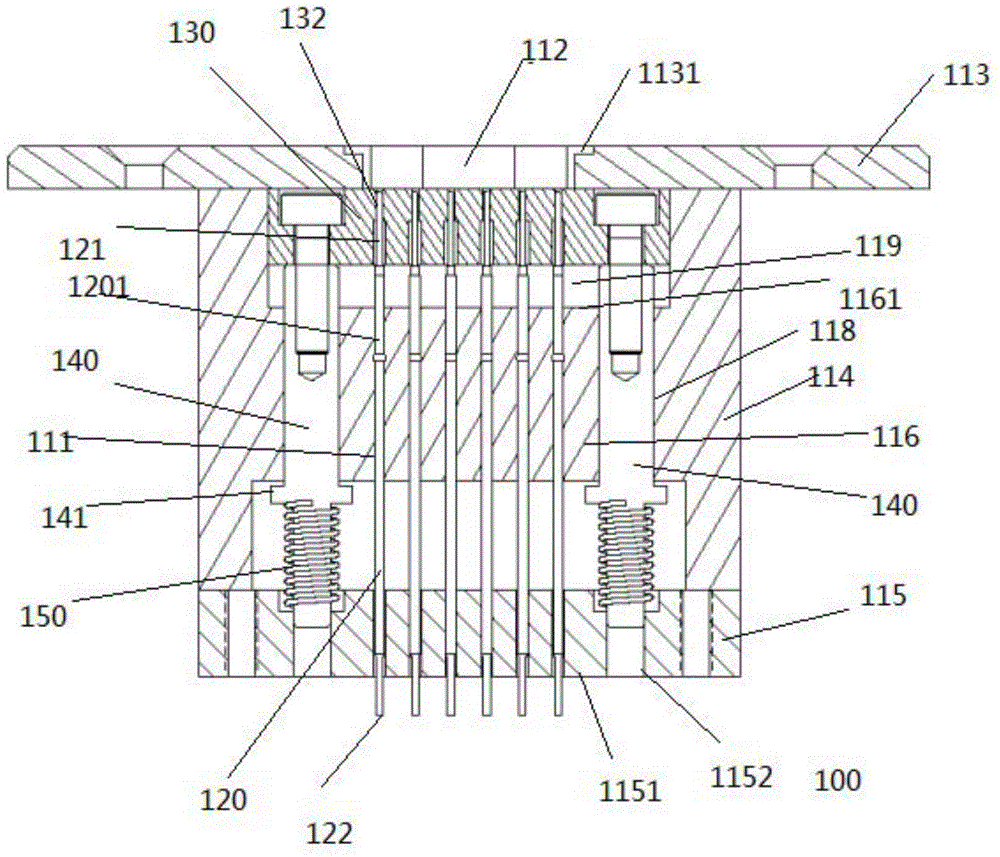

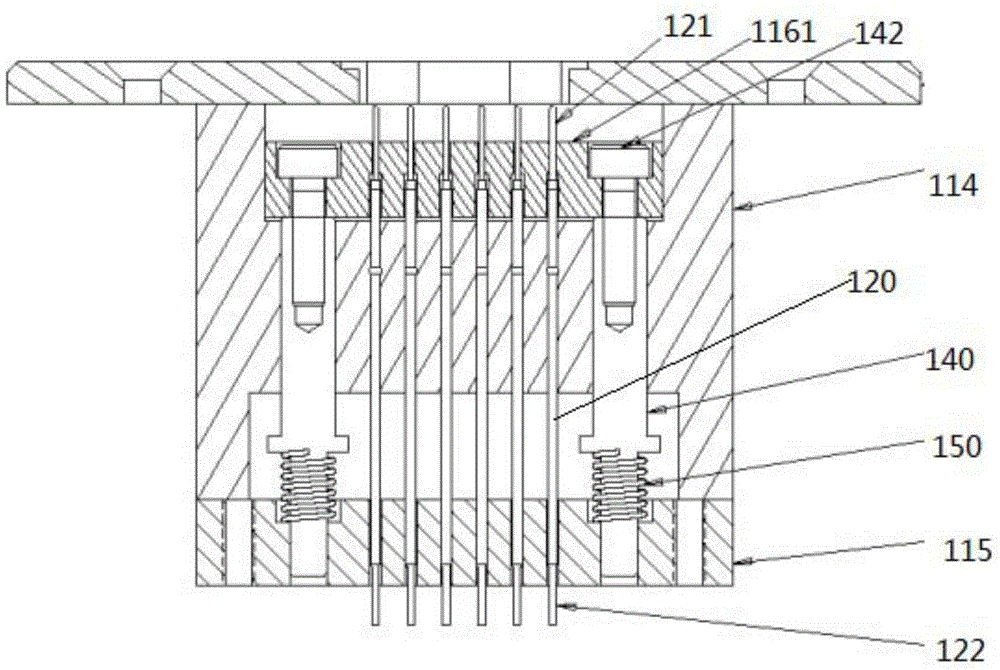

[0034] Such as Figure 1 to Figure 5 As shown, the connector test socket 100 includes a housing 110 and a probe 120 . The housing 110 has a probe fixing hole 111 extending along the connector insertion direction. The probe 120 is fixedly disposed in the probe fixing hole 111 . The housing 110 is provided with a first through hole 112 for inserting the connector under test. The first through hole 112 communicates with the probe fixing hole 111 , so that the connector under test inserted in the first through hole 112 can be connected with the probe 120 disposed in the probe fixing hole 111 . For example, the connecting terminal of the connector is removably inserted into the probe 120 in the probe fixing hole 111 .

[0035] In the example shown in the figure, the housing 110 includes a front plate 113 , a probe base 114 and a bottom plate 115 , and the front pla...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com