An installation method of an optical fiber temperature measuring probe inside a pre-installed conduit-type transformer

An installation method and optical fiber temperature measurement technology, applied in transformer/inductor parts, transformer/inductor coil/winding/connection, electrical component structure association, etc., can solve the difficulty of temperature measurement optical fiber damage, collision, and replacement of optical fiber probes It can save maintenance costs, save installation time, and avoid poor contact.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

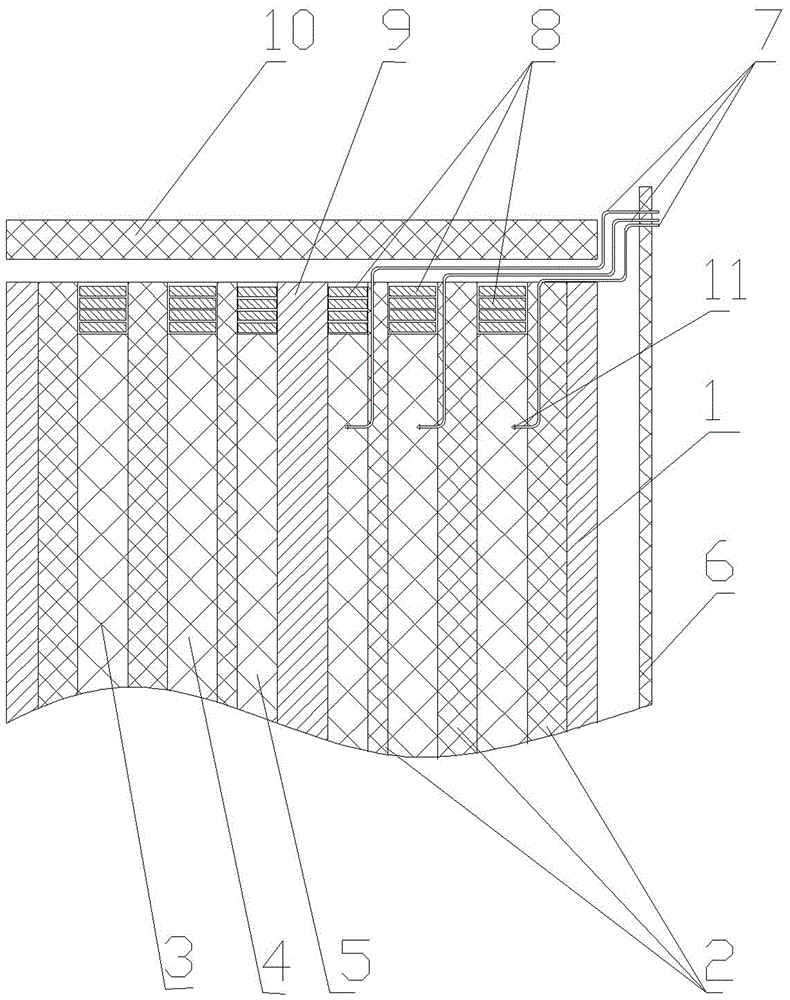

[0028] as attached figure 1 As shown, the present invention relates to a method for installing an optical fiber temperature measuring probe inside a preset conduit type transformer, which specifically includes the following steps:

[0029] (1) Select the insulating conduit 7 equal to the number of optical fiber temperature measuring probes, and calculate the length of the insulating conduit 7 according to the design drawings: the insulating conduit 7 preset in the low-voltage winding 5 and the insulating conduit preset in the medium-voltage winding 4 The length difference of 7 is the sum of the thickness of the paper tube 2 and the thickness of the medium-voltage winding 4; the length difference between the insulating conduit 7 preset in the medium-voltage winding 4 and the insulating conduit 7 preset in the high-voltage winding 3 is the and the thickness of the high-voltage winding 3, and then make a mark for distinction on each insulating conduit 7;

[0030] (2) Carry out w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com