Ceramic diaphragm and preparation method and application thereof

A technology of ceramic diaphragm and ceramic coating, applied in structural parts, electrical components, battery pack parts, etc., can solve the problem that battery diaphragm cannot have both electrochemical performance and safety performance at the same time, and achieve good electrochemical performance and safety. properties, the effect of increasing mechanical properties and heat shrinkage properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

[0034] As a preferred embodiment of the present invention, the binder is an aqueous polyacrylate emulsion. On the one hand, the water-based polyacrylate emulsion is a hydrophilic system, which is very environmentally friendly; on the other hand, the water-based polyacrylate emulsion has a self-crosslinking function, and it can be used in conjunction with small-sized inorganic ceramic powders and one-dimensional nanomaterials. Obtain a ceramic diaphragm with higher mechanical properties, high adhesion strength and high air permeability.

[0035] In the present invention, the ceramic coating further contains a dispersant. The content of the dispersant can be selected according to the content of the ceramic particles. Preferably, in the ceramic coating, based on 100 parts by weight of inorganic ceramic powder, the content of the dispersant is 0.4-4 wt. share. The dispersant can be various existing substances that can promote the uniform dispersion of the components in the coati...

Embodiment 1

[0049] This example is used to illustrate the ceramic diaphragm provided by the present invention and its preparation method.

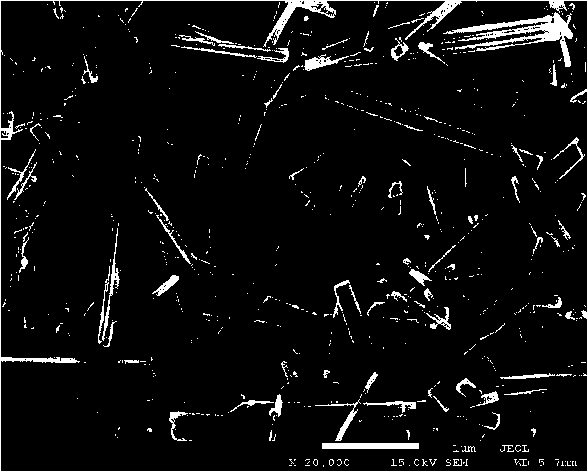

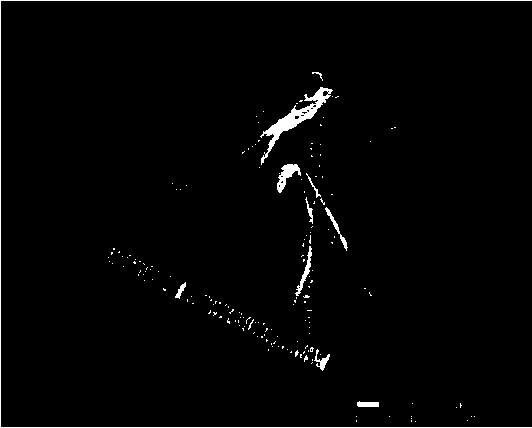

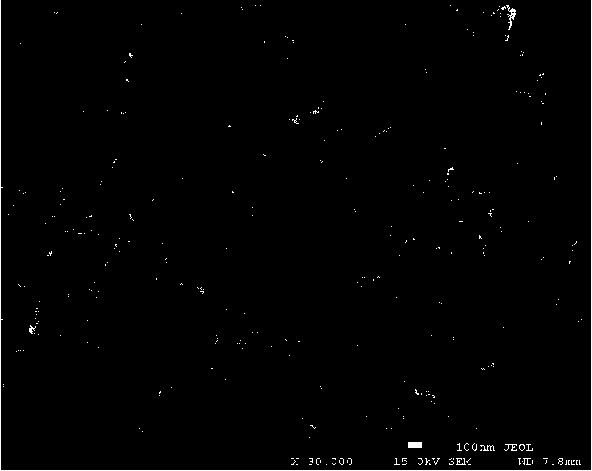

[0050] In this embodiment, the composition and content of the ceramic slurry are: alumina powder (with a particle size of 80-100nm): 100 parts by weight; titanium dioxide nanorods (the SEM morphology of which is as follows figure 1 As shown, the diameter is 40-200nm, the length is 0.5-10μm): 11 parts by weight; aqueous self-crosslinking polyacrylate emulsion (1005 emulsion, Shanghai Aigao Chemical Co., Ltd.): 5.55 parts by weight; PEG (molecular weight 10000g / mol): 1.11 parts by weight, PVA: 1.11 parts by weight.

[0051] The preparation method is as follows: (1) Disperse alumina powder in an appropriate amount of water to form an alumina suspension; (2) Disperse titanium dioxide nanorods with an ultrasonic breaker to obtain an aqueous dispersion of titanium dioxide nanorods; Add alumina suspension, PEG, and PVA to the water dispersion of the stick,...

Embodiment 2

[0053] In this embodiment, the composition and content of the ceramic slurry are: alumina powder (with a particle size of 80-100nm): 100 parts by weight; titanium dioxide nanorods (the SEM morphology of which is as follows figure 1 As shown, the diameter is 40-200nm, the length is 0.5-10μm): 25 parts by weight; water-based self-crosslinking polyacrylate emulsion (1005 emulsion, Shanghai Aigao Chemical Co., Ltd.): 7.25 parts by weight; PEG (molecular weight 10000g / mol): 1.25 parts by weight, PVA: 1.25 parts by weight.

[0054] The preparation method is as follows: (1) Disperse alumina powder in an appropriate amount of water to form an alumina suspension; (2) Disperse titanium dioxide nanorods with an ultrasonic breaker to obtain an aqueous dispersion of titanium dioxide nanorods; Add alumina suspension, PEG, and PVA to the water dispersion of the stick, stir until uniformly dispersed, and obtain a mixed dispersion; (4) continue to add 1005 emulsion under stirring, and obtain ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap