Feeder insert for a vertically split casting mould

A technology of vertical separation and feeder, which is applied in the direction of mold, mold composition, casting molding equipment, etc., and can solve problems such as unsuitable feeder components

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

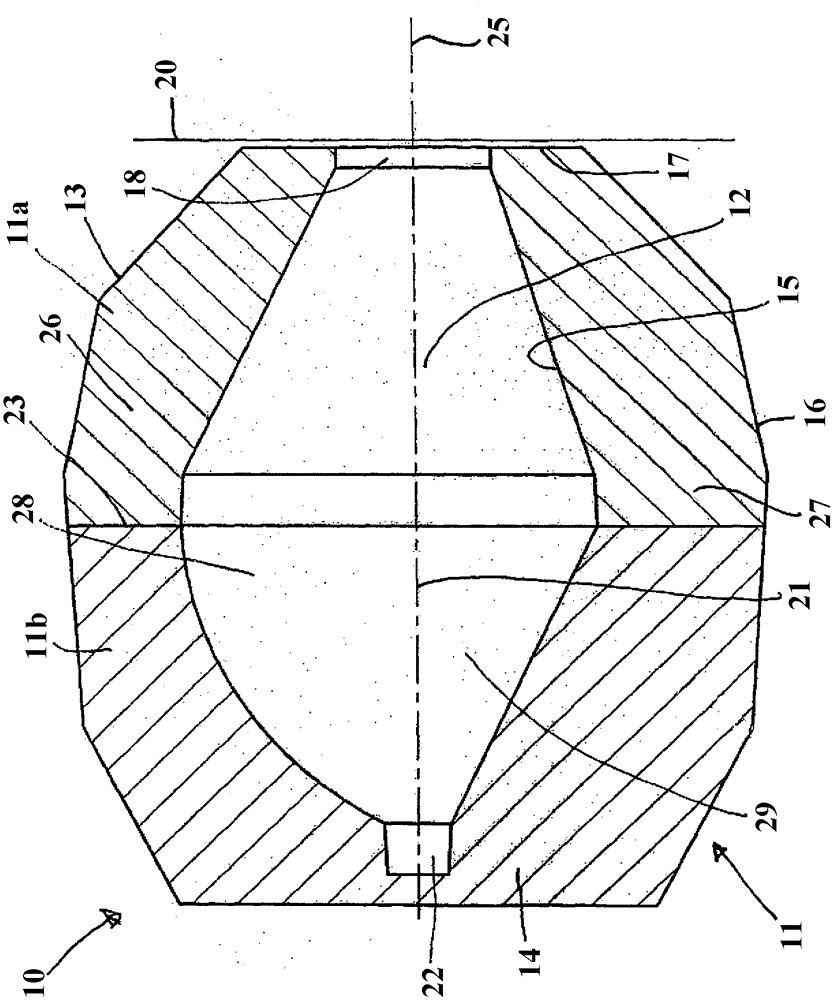

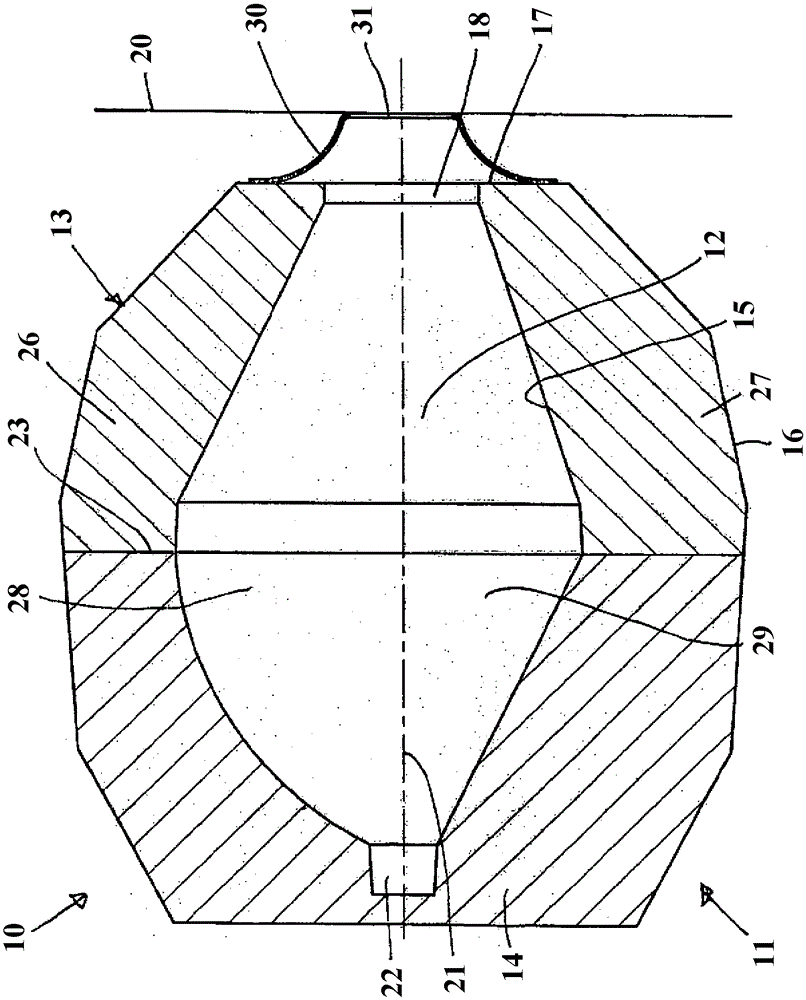

[0018] Depend on figure 1 The visible hopper insert 10 has a hopper body 11 comprising a wall region 13 and a cover region 14 surrounding a cavity 12 which is the interior as a so-called hopper volume. The feeder body has an outer face 16 of the wall region 13 and an inner face 15 surrounding the interior cavity 12 as well as a bottom face 17 in which a feeder opening 18 is formed.

[0019] The feeder insert 10 shown in the "flat" arrangement is to be associated with a vertical mold half 20, for which purpose the feeder insert can be plugged into a not shown structure that is inserted into the mold Attach the molding mandrel at the model. The cling-on mandrel protrudes through the feeder opening 18 in the bottom surface 17 and extends into the cover region 14 of the feeder insert 10, wherein the top end for receiving the cling-on mandrel is formed in this cover region 14 The opening 22. During the overmolding it can be the case that the tip of the overmolding mandrel penetr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com