Ditching and fertilizing integrated machine

An all-in-one machine and fertilization box technology, applied to fertilization devices, excavation/covering trenches, planting methods, etc., can solve the problems of small ditch width, unsatisfactory ditch width, and large running resistance, etc., to achieve Large depth, good ditch fertilization and soil covering effect, and large ditch width

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

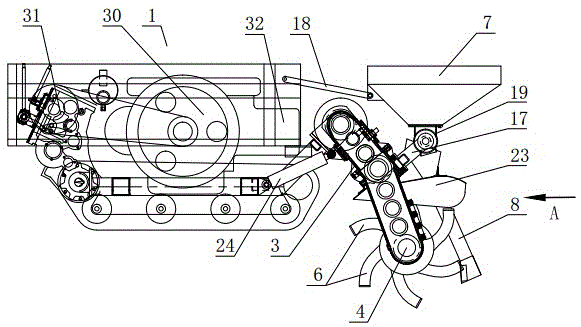

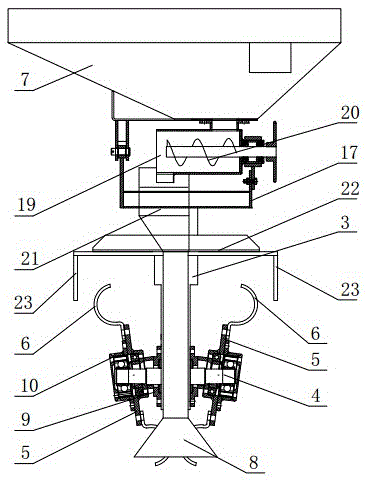

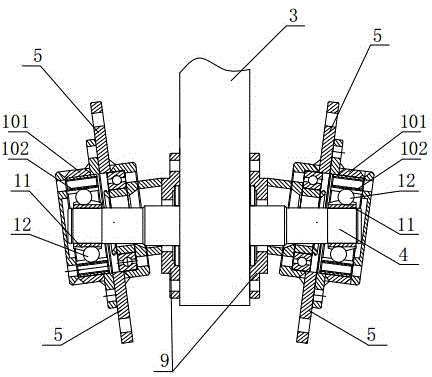

[0023] Such as figure 1 and Figure 4 The shown ditching and fertilizing integrated machine includes a frame 2 that can be connected to the power locomotive 1, and a gearbox 3 that is connected to the power mechanism is hinged on the frame 2. In this embodiment, the above-mentioned power mechanism Power comes from the power machine of power locomotive 1, also can adopt independent diesel engine to drive above-mentioned gearbox 3 certainly, the lifting power mechanism that drives gearbox 3 to swing is housed on frame 2, in the present embodiment, this lifting power mechanism is hinged on Oil cylinder 24 on the vehicle frame of power locomotive 1, the bottom of gearbox 3 is equipped with the power take-off shaft 4 that horizontal arrangement is equipped with, and the concrete structure of gearbox 3 is prior art, repeats no more here, power connection on the power take-off shaft 4 There are two ditching mounts 5 oppositely arranged, and a plurality of ditching knives 6 along its...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com