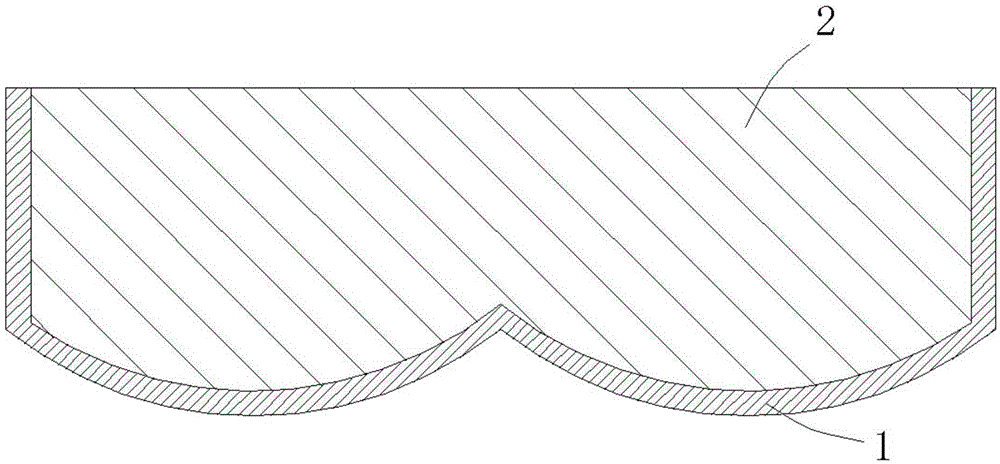

Damping cushion block and fabrication method thereof

A technology for a shock-absorbing cushion block and a manufacturing method, which is applied to clothing, footwear, shoe soles, etc., can solve the problems of being difficult to repair, easy to be punctured, and the strength of the air cushion block is not high, and the manufacturing method is simple and effective, not easy to damage, and saves money. effect of material

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

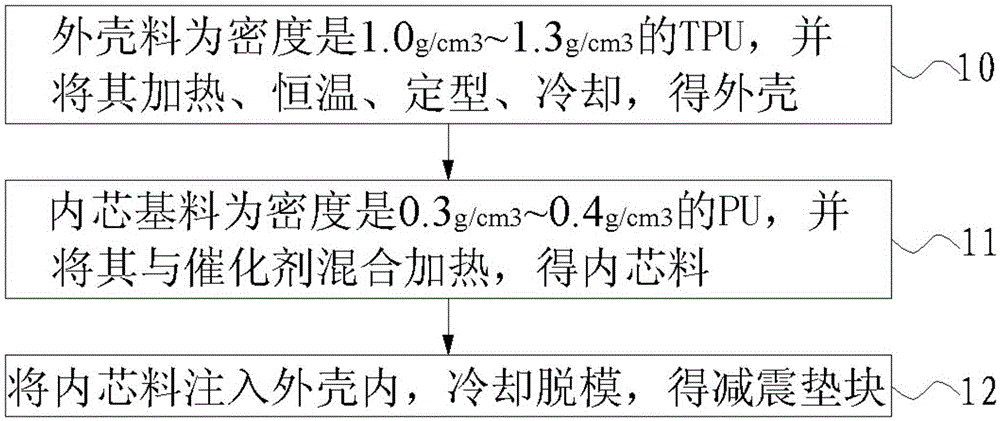

Embodiment 1

[0035] refer to figure 2 , the manufacture method of damping pad, comprises the following steps:

[0036] Step 10: Select the TPU supplied by Wenzhou Huafeng Industrial Group Co., Ltd. for the shell material, and control the density of the shell material at 1.0g / cm 3 , Put the shell material into the material tank of the TY8112 plastic injection machine supplied by Dongguan Taiyu Plastic Machinery Co., Ltd., heat it to 130°C, and keep the temperature constant for 15s, and then inject it into the mold of the plastic injection machine to shape it. After cooling Obtain the shell, and then put the shell into the mold of the DL330PU pouring machine supplied by Wenzhou Daling Machinery Manufacturing Co., Ltd.

[0037] Step 20: Choose the PU supplied by Wenzhou Huafeng Industrial Group Co., Ltd. as the base material for the inner core, and choose a mixture of triethylenediamine and ethylene glycol as the catalyst, and the ratio is 1:800. Put the base material and catalyst into the ...

Embodiment 2

[0040] refer to Figure 4 , the manufacture method of damping pad, comprises the following steps:

[0041] Step 10: Select the rubber of model 2003 supplied by Lianyungang Daolang Chemical Co., Ltd. for the shell material, and control the density of the shell material at 1.3g / cm 3 , Put the shell material into the material tank of the TY8112 plastic injection machine supplied by Dongguan Taiyu Plastic Machinery Co., Ltd., heat it to 170°C, and keep the temperature constant for 25s, and then inject it into the mold of the plastic injection machine to shape it. After cooling A shell with a cavity is obtained. Then put the shell into the mold of the DL330PU type pouring machine supplied by Wenzhou Daling Machinery Manufacturing Co., Ltd.

[0042] Step 20: Choose the EVA supplied by Yongcheng Adhesive Products Industrial Co., Ltd. as the base material for the inner core, and choose a mixture of triethylenediamine and ethylene glycol as the catalyst, and the ratio is 1:1000. Put ...

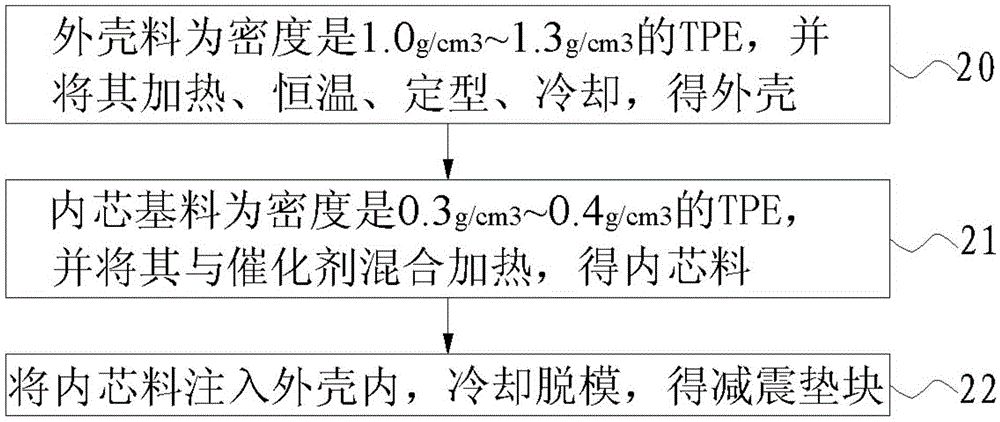

Embodiment 3

[0045] refer to image 3 , the manufacture method of damping pad, comprises the following steps:

[0046] Step 10: Select the TPE with product number ZF75A-4 supplied by Dongguan Subo Rubber & Plastic Co., Ltd. for the shell material, and control the density of the shell material at 1.2g / cm 3 , Put the shell material into the material tank of the TY8112 plastic injection machine supplied by Dongguan Taiyu Plastic Machinery Co., Ltd., heat it to 170°C, and keep the temperature constant for 20s, and then inject it into the mold of the plastic injection machine to shape it. After cooling Obtain the shell, and then put the shell into the mold of the DL330PU pouring machine supplied by Wenzhou Daling Machinery Manufacturing Co., Ltd.

[0047] Step 20: Choose the TPE with product number ZF75A-4 supplied by Dongguan Subo Rubber & Plastic Co., Ltd. as the base material for the inner core, and choose a mixture of triethylenediamine and ethylene glycol as the catalyst at a ratio of 1:9...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Density | aaaaa | aaaaa |

| Density | aaaaa | aaaaa |

| Density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com