Flexible fixture for batch machining of shaft workpieces

A technology of shaft workpieces and flexible fixtures, which is applied in the direction of metal processing machinery parts, manufacturing tools, metal processing equipment, etc., can solve the problems of poor quality assurance, high comprehensive cost, and high input cost, so as to reduce fixture investment and comprehensive cost. Low, the effect of improving the processing quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

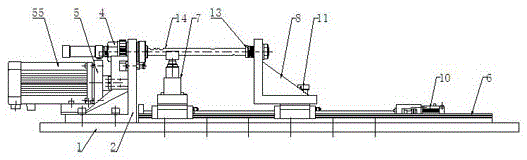

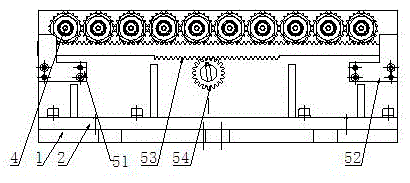

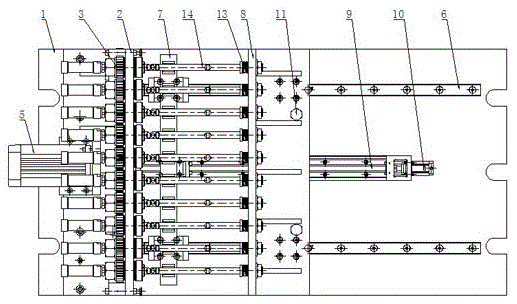

[0020] Such as figure 1 , figure 2 , image 3 and Figure 4 As shown, a flexible fixture for batch processing shaft workpieces includes a fixture bottom plate 1, a left bracket 2 is fixed on the left plate surface of the fixture bottom plate 1 by bolts, and a plurality of bearing holes arranged at intervals are arranged on the top of the left bracket 2 , each bearing hole is provided with a left sliding bearing 3, the cavity of the left sliding bearing 3 is provided with a centering positioning clamping mechanism 4, and the outer surface of the left bracket 2 stockings is provided with an indexing system 5, the indexing system 5 can Simultaneously drive a plurality of centering positioning clamping mechanisms 4; the linear guide rail 6 is fixed on the right plate surface of the fixture bottom plate 1 through countersunk bolts, and the linear guide rail 6 is provided with auxiliary support mechanisms 7 and right brackets 8 arranged at intervals for auxiliary support The me...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com