Vacuum mold made from epoxy resin compound materials, for preparing carbon nanotubes

An epoxy resin and composite material technology, applied in the field of vacuum molds, can solve the problems of reducing the quality of castings, poor sealing, difficult demoulding, etc., and achieve the effects of reducing difficulty, low cost, and eliminating uneven casting

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

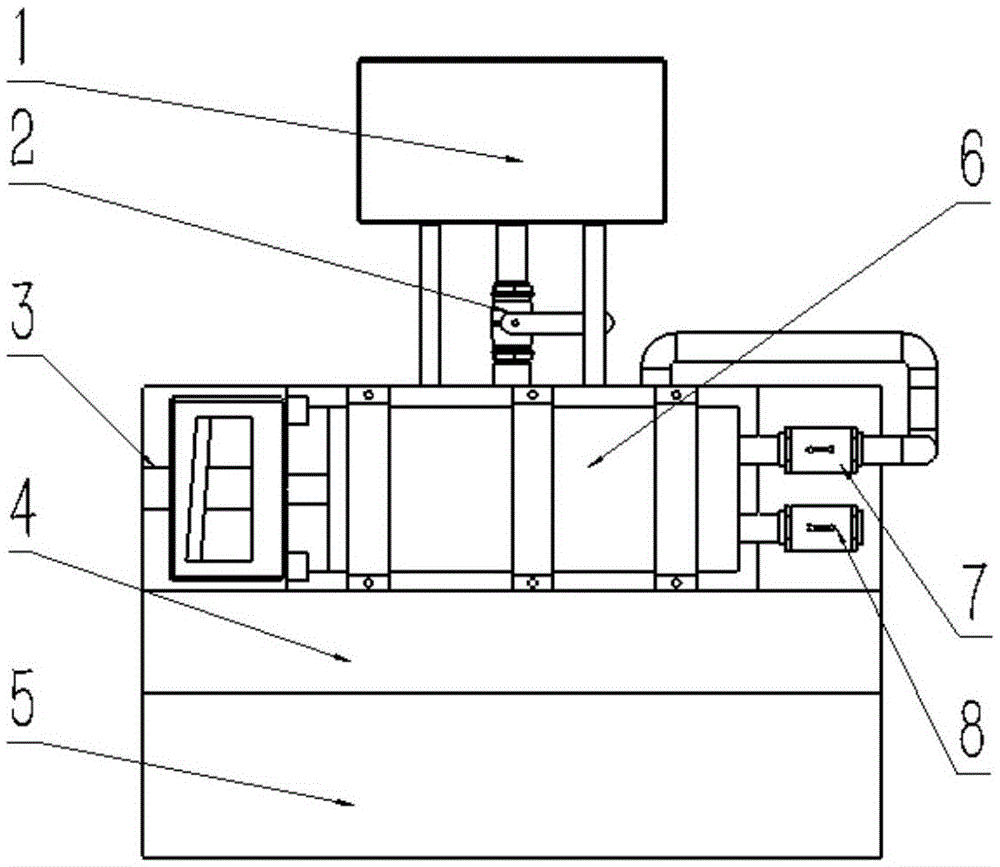

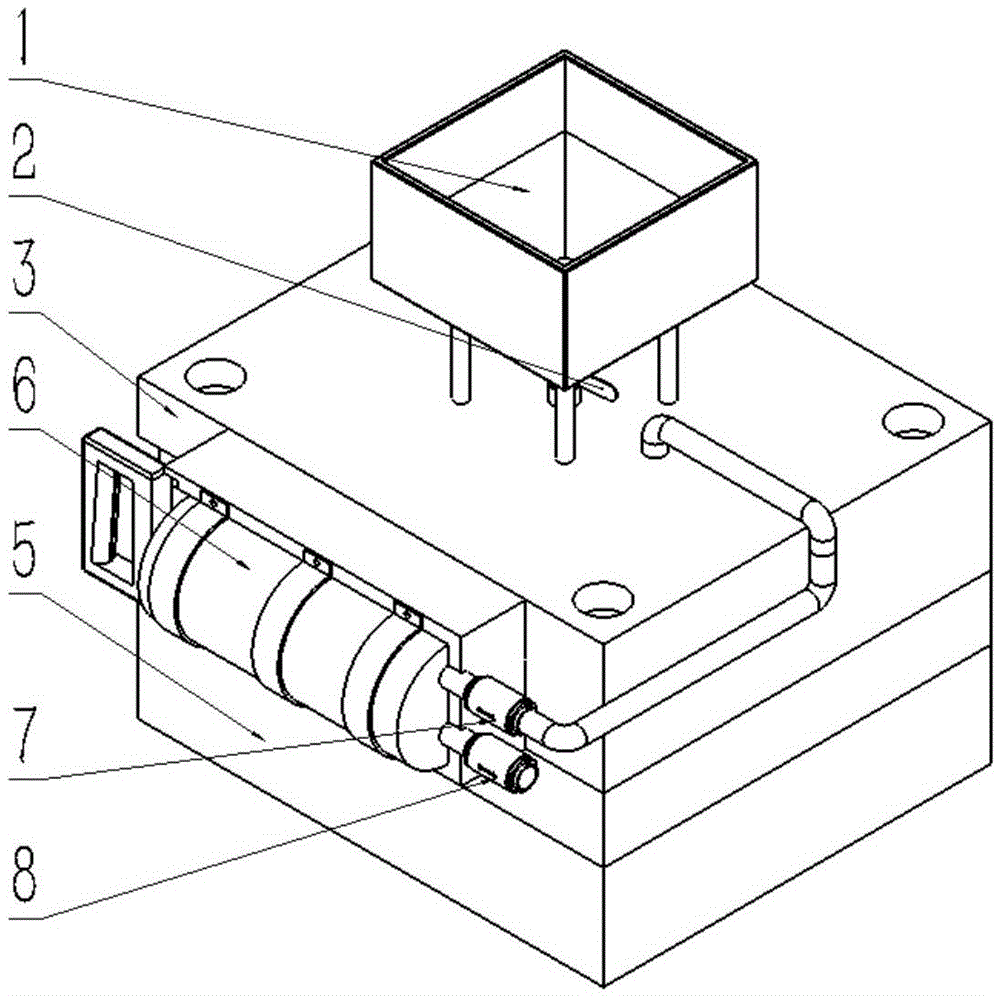

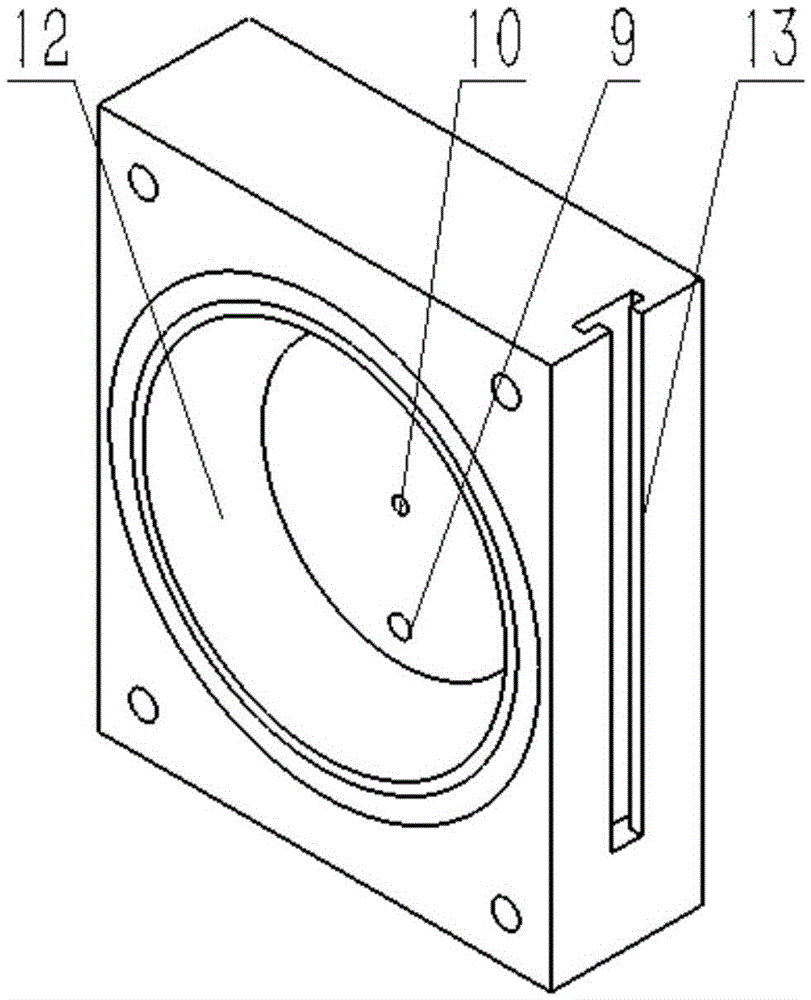

[0023] Such as Figure 1 to Figure 6 Shown, a kind of vacuum mold that is used to prepare carbon nanotube epoxy resin composite material comprises upper mold 4, middle mold 5 and lower mold 6; The bottom surface of described upper mold 4 is provided with first concave platform 12, and described first A concave platform 12 is provided with a pouring port and an exhaust hole 9, and the pouring port 10 is connected with the storage bin 1 through the pouring valve 2; the top surface of the lower mold 6 is provided with a second concave platform 16; the middle mold 5 Located between the upper mold 4 and the lower mold 6, and the upper part of the outer periphery of the middle mold 5 matches the shape of the first concave platform 12, the lower part matches the shape of the second concave platform 16, and the middle part matches the shape of the product A cavity is formed, and the middle mold 5 is embedded in the concave platform of the upper mold 4 and the lower mold 6, and the upp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com