Double coil large diameter plate installation rail vehicle anti-skid exhaust valve

A technology for rail vehicles and exhaust valves, applied in the directions of valves for ventilation, valve details, valve devices, etc., can solve the problems affecting the execution efficiency and response speed of the anti-skid system, the complex air path structure of the exhaust valve, affecting the excitation of the iron core. Efficiency and response reliability issues, to achieve the effect of improving response speed and system reliability, improving system reliability, and facilitating maintenance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

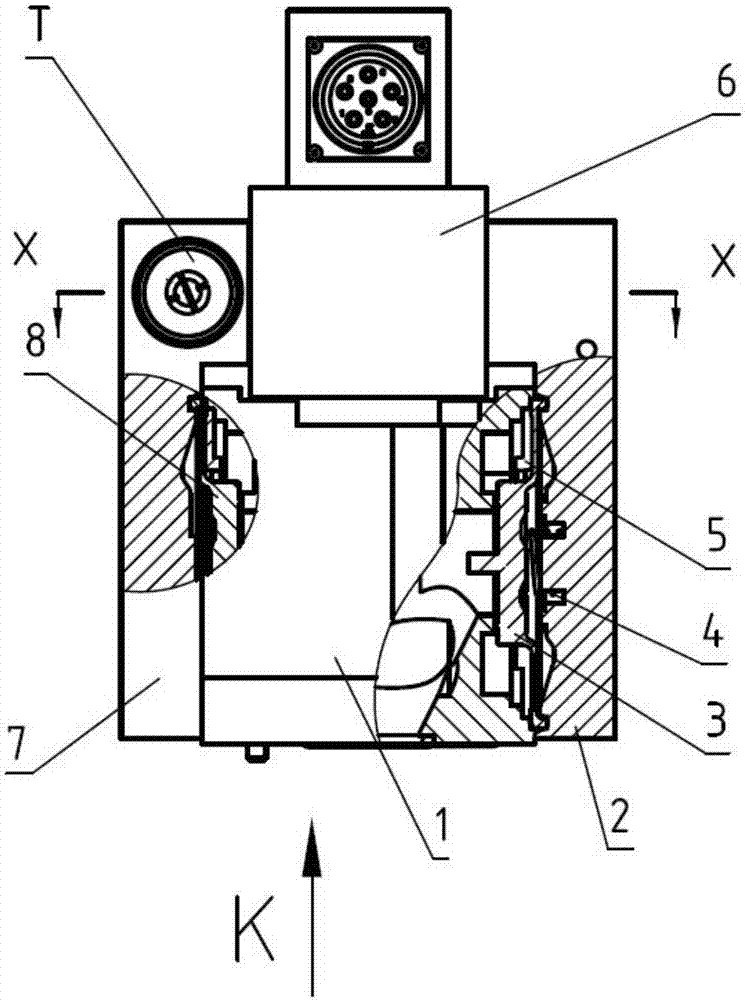

[0026] see figure 1 , a double-coil large-diameter plate-mounted anti-skid exhaust valve for rail vehicles, the exhaust valve includes a middle valve body 1, the left and right sides of the middle valve body 1 are respectively connected to the intake side plate 2 and the exhaust side plate through hexagonal bolts 7 connections.

[0027] Both the intake side plate 2 and the exhaust side plate 7 are provided with a pre-control air path structure, wherein the exhaust side plate 7 is provided with an independent exhaust port T.

[0028] An exhaust diaphragm 8 and an exhaust diaphragm support ring are installed between the middle valve body 1 and the exhaust side plate 7, and the exhaust diaphragm 8 divides the passage between the middle valve body 1 and the exhaust side plate 7 into an exhaust membrane. Diaphragm left chamber B1 and exhaust diaphragm right chamber B2. The exhaust diaphragm supporting ring is arranged on the outer ring of the exhaust diaphragm on the side of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com