Vehicle frame traveling mechanism device

A technology of moving mechanism and frame, applied in the direction of load-bearing body structure, superstructure, vehicle components, etc., can solve the problems of poor passability, poor stability, chassis mopping, etc., and achieve the effect of good passability and good stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

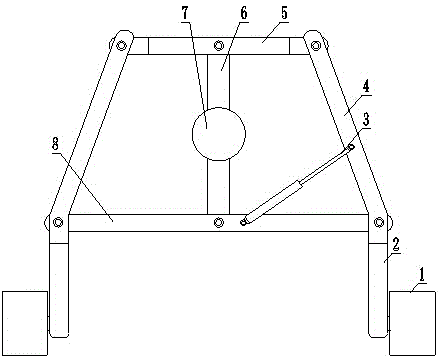

[0019] Such as Figure 1-Figure 2 As shown, the structure of the crawler-type low-frame mechanism is: the crawler-type low-frame mechanism is a single group mechanism, and the upper end is provided with a pull rod 5, and the two ends of the pull rod 5 are respectively hinged with the upper ends of the two rocking rods 4, and the bridge frame 18 The two ends of the rocker are respectively hinged with the lower ends of the two rockers-4, the lower end of the rocker-4 is fixedly connected with the upper end of the swing rod-2, the lower end of the swing rod-2 is connected with the crawler belt 1, and the middle of the tie rod-5 and the bridge frame-8 is hinged. Frame seat one 6, the middle part of frame seat one 6 is fixedly connected with the middle part of vehicle frame one 7, one side of bridge frame one 5 is equipped with hydraulic cylinder one 3, and the other end of hydraulic cylinder one 3 is installed on the rocker on the same side The lower end of a 4.

Embodiment 2

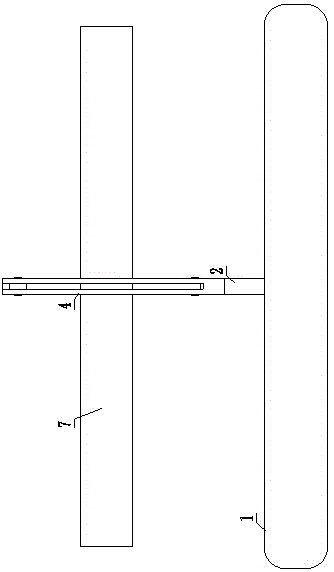

[0021] Such as Figure 3-Figure 4 As shown, the structure of the wheeled low-frame mechanism is: the wheeled low-frame mechanism is a combined mechanism, and the wheeled low-frame mechanism is two single-group mechanisms that are set correspondingly. Two ends, the structure of a single group is as follows: the upper end is provided with a pull rod two 13, the two ends of the pull rod two 13 are respectively hinged with the upper end of the rocker two 12, the two ends of the bridge frame two 15 are respectively hinged with the lower end of the rocker two 12, and the two ends of the rocker two 12 are respectively hinged. The lower end is fixedly connected to the swing rod two 10, the lower end of the swing rod two 10 is equipped with the wheel one 9, the middle hinged vehicle frame seat two 14 of the pull rod two 13 and the bridge frame two 15, and one side of the bridge frame two 15 is equipped with a hydraulic cylinder two 11, and the hydraulic pressure Cylinder two 11 other e...

Embodiment 3

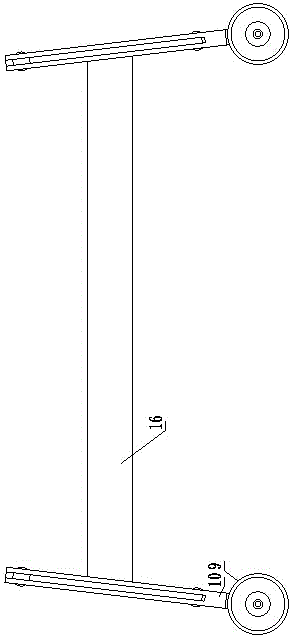

[0023] Such as Figure 5-Figure 6 As shown, the structure of the wheeled overhead mechanism is as follows: the wheeled elevated mechanism is a combined mechanism, and the wheeled elevated mechanism is two single-group mechanisms that are set correspondingly. , the bottom of the frame seat 3 22 of the two single-group mechanisms is hinged with the two ends of the longitudinal bridge 25, and the structure of the single-group mechanism is: the upper end is provided with a pull rod 3 21, and the two ends of the pull rod 3 21 are respectively hinged to the rocker 3 on both sides. The upper end of 20, the lower end of the rocking bar 3 20 of bridge frame 3 23 hinged respectively; The other end of three 19 is installed on the lower end of rocking bar three 20 on the same side, the lower end of swing bar three 18 is equipped with wheel two 17, the middle hinged frame seat four 26 of longitudinal tie bar 24 and longitudinal bridge frame 25, the lower end of car frame seat four 26 Fixe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com