Vertical agriculture picking mechanism

An agricultural and pipe-through technology, applied in the field of vertical agriculture, to achieve the effect of improving picking efficiency and improving efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

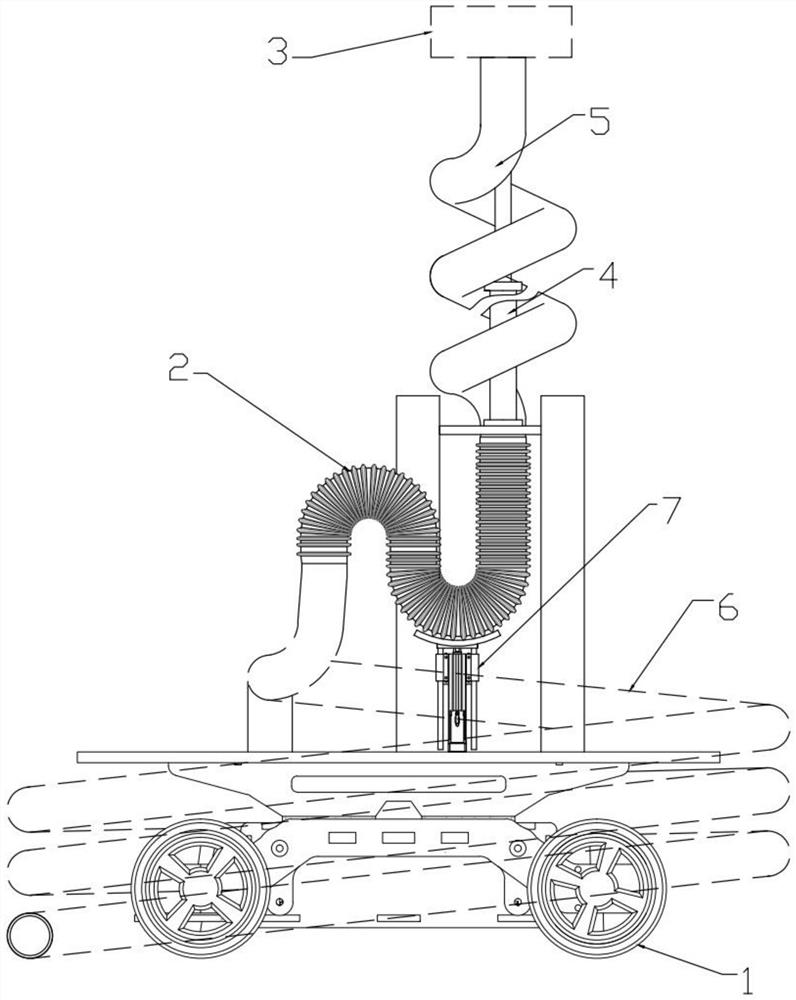

[0026] This embodiment is basically as figure 1 Shown: The vertical agricultural picking mechanism includes a self-propelled device, a dump device and a picking device. The self-propelled device adopts an AGV trolley 1, and the picking device adopts a negative pressure absorption type self-priming picker 3. The working part of the picker 3 is Cylindrical, the picker 3 can be installed on the AGV trolley 1 through a telescopic bracket, or the picking action execution part of the picker 3 itself can be telescopic. In this embodiment, it is preferably installed on the AGV trolley 1 through the telescopic cylinder 4 . The dumping device is an S-shaped through pipe 2 vertically erected. The S-shaped through pipe 2 is a threaded pipe made of plastic and can be bent freely. The two ends of the S-shaped through pipe 2 are respectively an inlet and an outlet. The discharge port of the discharge port is communicated through the telescopic hose 5, and the telescopic hose 5 spirals into ...

Embodiment 2

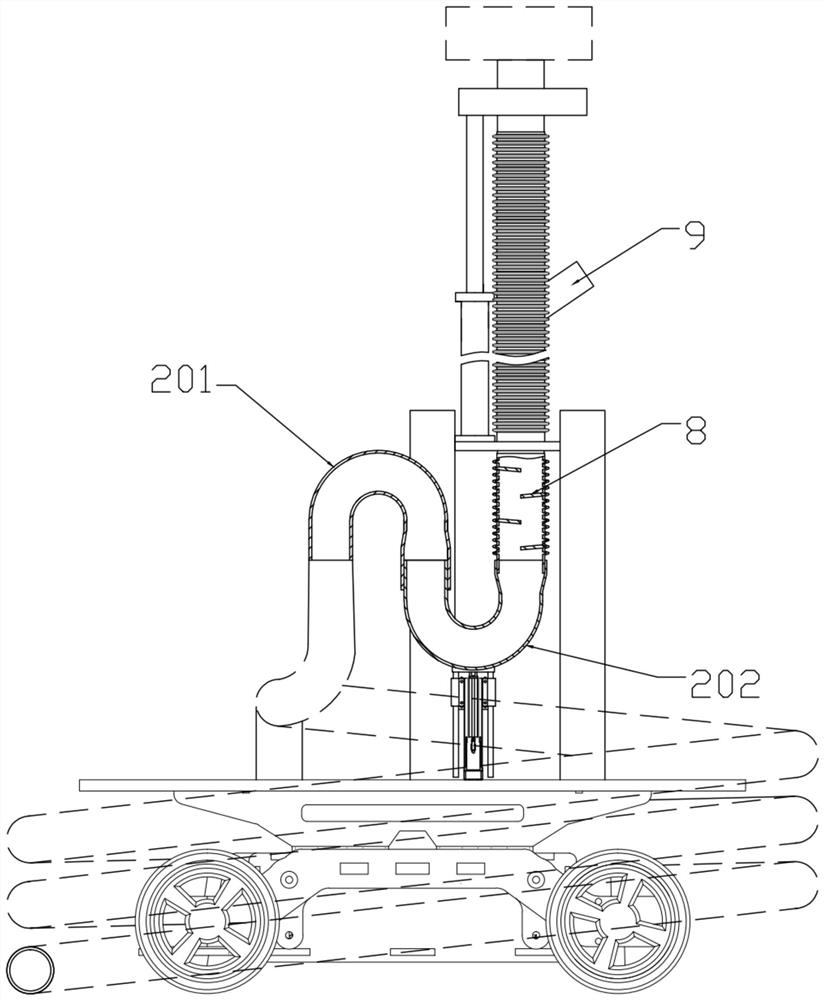

[0029] This example is attached figure 2 As shown, the difference from Embodiment 1 is that: the S-shaped through pipe 2 is connected by an upper U-shaped pipe and a lower U-shaped pipe, the upper U-shaped pipe is fixed on the AGV trolley 1, and the lower U-shaped pipe is passed through the sliding The bracket is slidably connected to the top surface of the AGV trolley 1, and one end of the upper U-shaped tube is docked with one end of the lower U-shaped tube. At the joint, the end of the lower U-shaped tube is inserted into the end of the upper U-shaped tube 201 and slides connection, and the connection is sealed by a sealing ring. The end of the lower U-shaped tube is inserted into the flexible hose 5 and is slidably connected with the lower end of the flexible hose 5, and the upper end of the upper U-shaped tube is inserted into the upper end of the slide pipe 6 away from the end of the lower U-shaped tube. Electric cylinder 7 is connected on the lower U-shaped pipe. The...

Embodiment 3

[0032] The difference from Embodiment 1 is that there are multiple S-shaped through-pipes 2 , and the number of S-shaped through-pipes 2 is determined according to the circumference around the top of the AGV trolley 1 and the length of a single S-shaped through-pipe 2 . The S-shaped through-pipe 2 is connected end to end, the entrance of the S-shaped through-pipe 2 at the head is communicated with the flexible hose 5, and the outlet of the S-shaped through-pipe 2 at the tail is communicated with the slide pipe 6.

[0033] The more the quantity of the S-shaped through pipe 2 is, the larger the fruit can be stored, which is more conducive to keeping the center of gravity of the whole picking mechanism at a low position.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com