Curve segment immersed tube binding jig frame supporting device and supporting method

The technology of a support device and a support method is applied in the field of curved section immersed tube tying tire frame support devices, which can solve the problems that the supports cannot correspond to the fixed beams and cannot support the steel cage, etc., so as to achieve better support, ensure the center of gravity, and good stability sexual effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

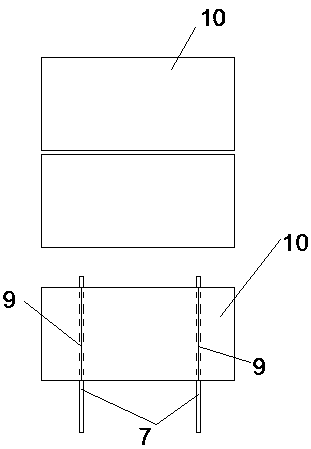

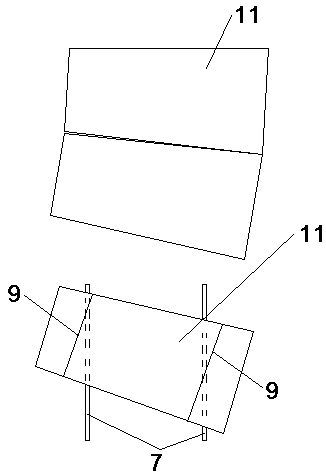

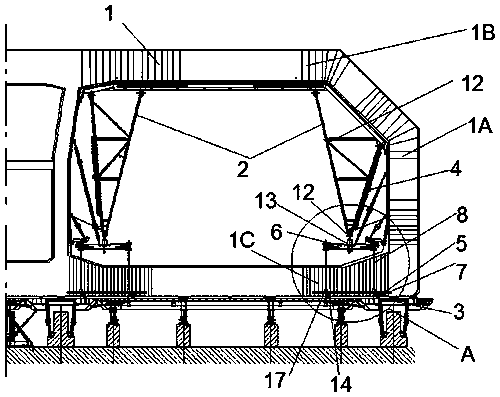

[0054] Such as image 3 , Figure 4 and Figure 5 As shown, the curved section immersed tube binding tire frame support device includes a basic support 12 for supporting the inner tire frame, the bottom of the basic support 12 is provided with a tire frame base 6, and a tire frame base 6 is connected below the tire frame base 6 for supporting the tire frame. The support member 8 of the frame base 6, the below of the support member 8 is provided with a load-sharing beam 5 transversely arranged on the fixed beam 7, and the load-distribution beam 5 extends to the below of the support member 8 along both sides of the fixed beam 7, so that The supporting member 8 can be installed vertically on the load sharing beam 5 .

[0055] At the same time, the reinforcement cage 1 of the immersed tube in the curved section includes wall reinforcement 1A, roof reinforcement 1B and floor reinforcement 1C. In order to ensure sufficient support for the reinforcement cage 1 of the curved section...

Embodiment 2

[0071] Such as image 3 , Figure 4 and Figure 5 As shown, the curved section immersed tube binding tire frame support method specifically includes the following steps:

[0072] a. Install the fixed beam 7, and install the fixed beam 7 on the sliding track 3;

[0073] b. Bind bottom plate reinforcement 1C, bind the lower half of the stirrup and the horizontal and vertical reinforcement of the first layer until it is completed;

[0074] c. Locate the load-sharing beam 5, stake out the load-sharing beam cylinders 17 at the ends of both sides of the immersed tube segment, and determine the positions of the centers of the remaining load-sharing beam cylinders 17 to complete the positioning of the load-sharing beam 5;

[0075] d. Fix the load sharing beam 5 and complete the binding of the bottom plate steel bar 1C;

[0076] e. Install the supporting member 8 , the tire frame base 6 and the tire frame base support 12 .

[0077] By installing the load-sharing beam 5, the gravit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com