Medicine placingtray

A medicine tray and medicine dispensing technology, applied in packaging and other directions, can solve the problems of slow operation, high error rate, cumbersome process, etc., and achieve the effect of reducing the error rate, reducing the error rate, and cleaning the environment.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

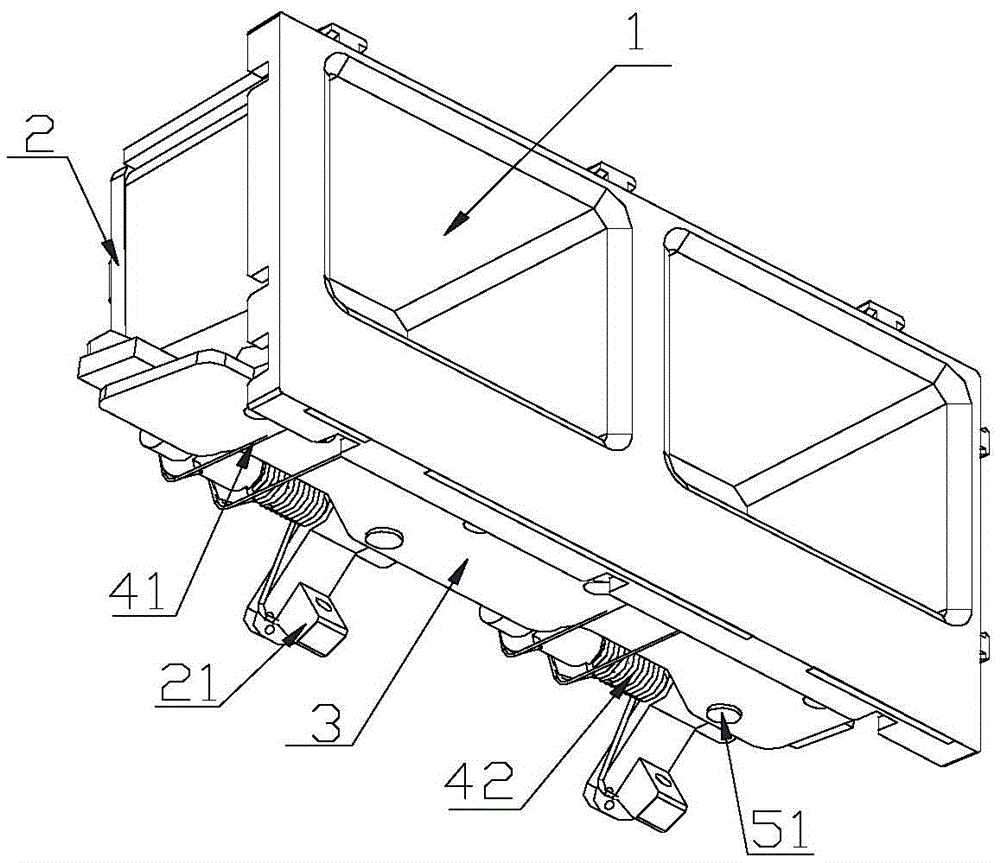

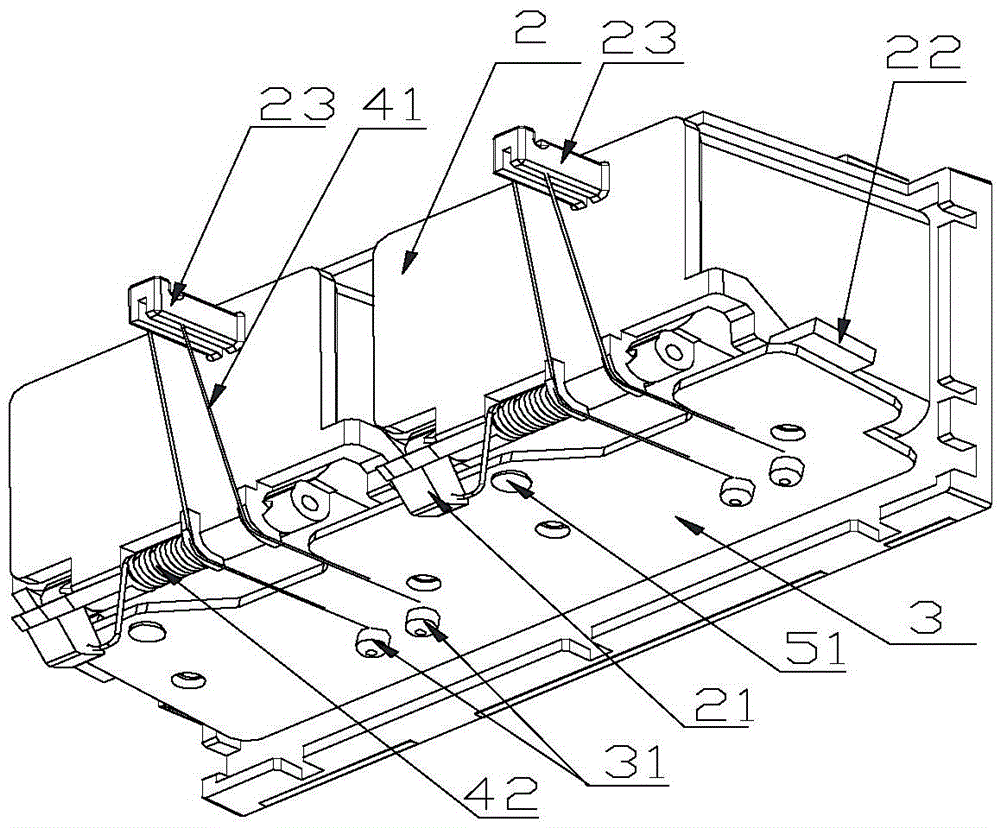

[0024] Such as figure 1 and figure 2 As shown, a medicine setting tray, the medicine setting tray includes a drug grid 1, a drug distribution mechanism and a detection mechanism, the drug distribution mechanism is located on the outside of the drug grid 1, the bottom surface 2 of the drug grid and the drug grid The side 3 of the drug compartment is movably connected, and the drug distribution mechanism is fixedly connected with the bottom surface 2 of the drug case and the side surface 3 of the drug case respectively, and the drug distribution mechanism drives the bottom surface 2 of the drug case to open and close. The drug dispensing mechanism includes a memory alloy wire 41, a torsion spring 42 and a power supply. The two ends of the memory alloy wire 41 are respectively fixedly connected to the bottom surface 2 of the drug case and the side surface 3 of the drug case. The bottom surface of the drug case 2 and the side 3 of the medicine grid are connected by a hinge, and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com