Continuous conveying device for crystal precipitation

A transmission device and crystal technology, applied in packaging and other directions, can solve the problems of unfavorable large-scale continuous production and cumbersome obtaining steps, and achieve the effect of improving continuous production capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] Below in conjunction with accompanying drawing and embodiment the present invention is further described:

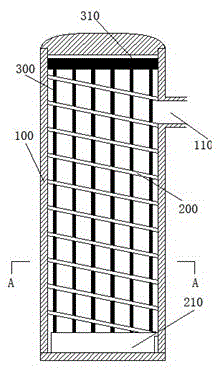

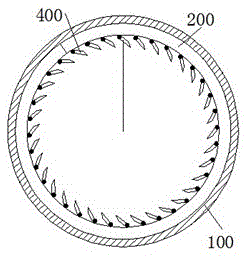

[0014] In this example, see figure 1 and figure 2 , the continuous conveying device for crystallization includes a cylindrical grid 300, a spring-shaped conveying paddle 200 and a cylindrical housing 100, the inner circumference of the conveying paddle 200 and the cylindrical grid 300 The outer circumference of the conveying paddle 200 is adapted to the inner circumference of the cylindrical housing 100, and the cylindrical grid 300, the conveying paddle 200 and the cylindrical housing 100 are sequentially nested to form three Layer nesting structure, one end inside the cylindrical housing 100 is provided with a motor-driven drive end cover 210 , and one end of the delivery paddle 200 is fixed on the drive end cover 210 . One end of the cylindrical housing 100 is provided with a discharge hole 110 matched with the conveying paddle 200 .

[0015] In the above-m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com