Demolding structure of multi-layer mold rubber vulcanizing machine

A technology of rubber vulcanization and demolding, applied in the field of demolding structure of multi-layer mold rubber vulcanizer, can solve the problems of difficulty in cleaning the pick-up mold, single function of the demolding mechanism, limitation of mold selection, etc., so as to improve the continuous production capacity, Reduce daily damage and maintenance, compact structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

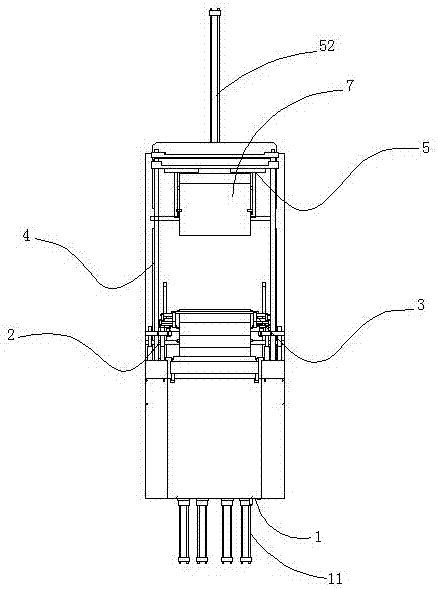

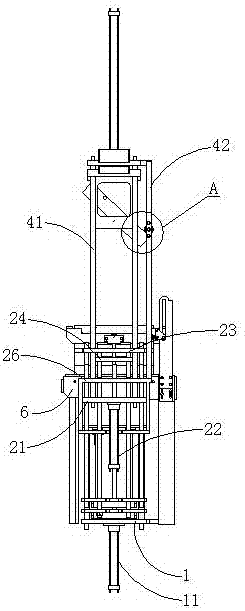

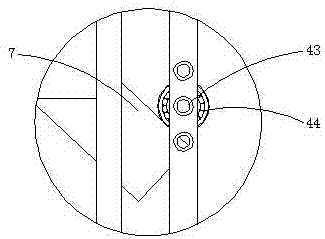

[0024] Such as Figure 1 to Figure 5 Shown is the structural representation of the present invention,

[0025] Wherein the reference signs are: main support 1, lower clap oil cylinder group 11, demoulding and ejecting group 2, demoulding frame plate 21, ejecting oil cylinder 22, ejecting plate 23, middle layer ejecting plate 24, demoulding pin group 25. Guide plate 26, flap group 3, upper flap group 31, flap connecting plate 32, guide groove 32a, buffer 33, connecting group 4, connecting bracket 41, connecting rod 42, guide wheel shaft 43, guide wheel 44, go up and clap group 5, go up and clap fixed rack 51, go up and clap oil cylinder 52, demoulding hook 53, go up and clap fixed pressing plate 54, slide rail 55, tooth bar 56, mounting bracket 57, intermediate support 6, mold 7.

[0026] Such as Figure 1 to Figure 5 as shown,

[0027] A d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com