Balance alarm and real-time protective device for aerial working platform of crawler travelling vehicle

A high-altitude work platform, real-time protection technology, applied in the direction of lifting devices, lifting equipment safety devices, etc., can solve the problems of increased center of gravity moment, reduced operating efficiency, and roll accidents of the operating platform, so as to achieve stable operation, ensure safety, The effect of high reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

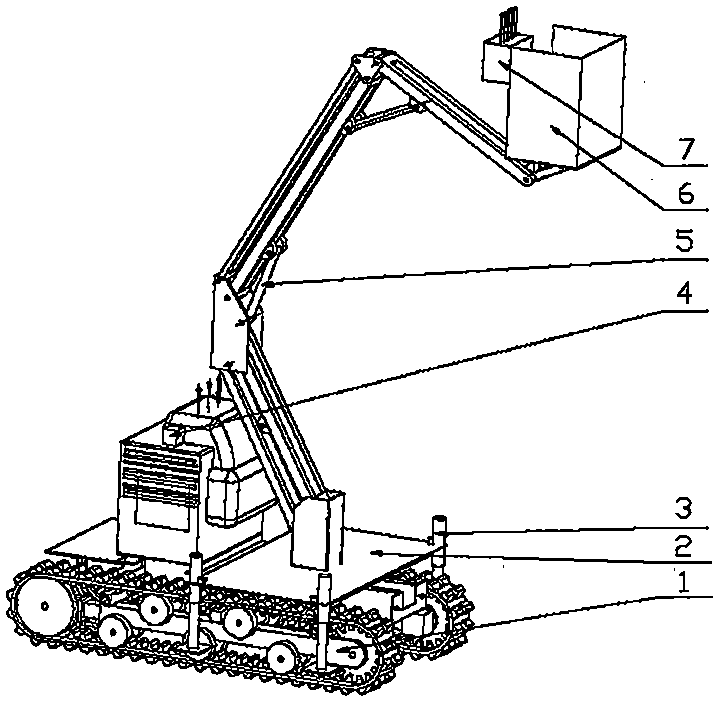

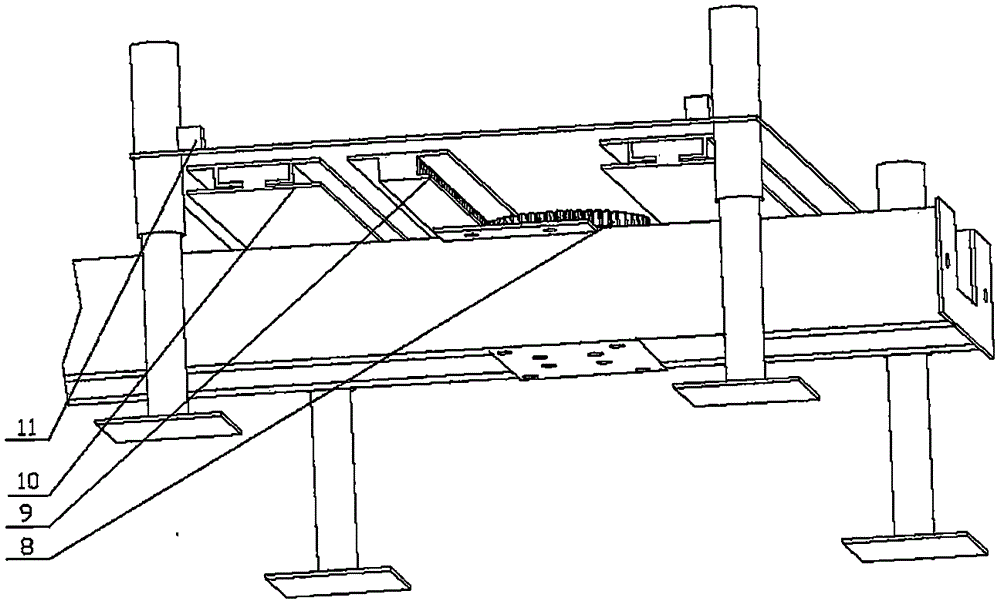

[0012] see figure 1 and figure 2 , the present invention includes a crawler walking system 1, four hydraulic cylinder telescopic outriggers 2, four pressure sensors 3, an ECU controller 4, a rack 5, a gear 6, a hydraulic motor 7, a working platform base 8, a slider 9, and a platform Lateral sliding T-shaped track 10.

[0013] The longitudinal beam of the above-mentioned crawler walking system 1 is equipped with two platform lateral sliding T-shaped rails 10 and a rotary gear 6 driven by a hydraulic motor 7 .

[0014] The slide block 9 corresponding to the T-shaped track 10 for lateral sliding of the platform and the rack 5 that drives the movement of the work platform base 8 are installed below the above-mentioned work platform base 8 .

[0015] The above-mentioned four hydraulic cylinder telescopic outriggers 2 are respectively installed at the four symmetrical top corners of the work platform base, and a hydraulic cylinder pressure sensor 3 is installed on the top of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com