Supporting steel structure for curved exterior curtain wall with spring device suspender and its construction method

A spring device and steel structure technology, applied in the direction of walls, building components, building structures, etc., can solve the problems of large vertical deflection, high cost, and large cross-section of components, and achieve the effect of simple adjustment and convenient installation and construction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

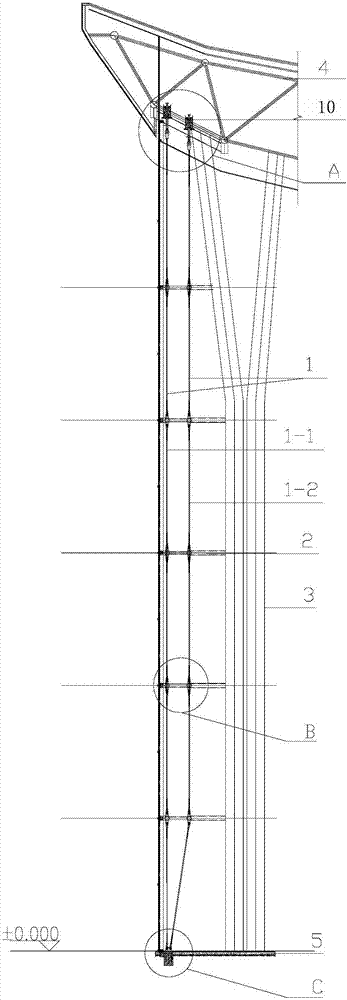

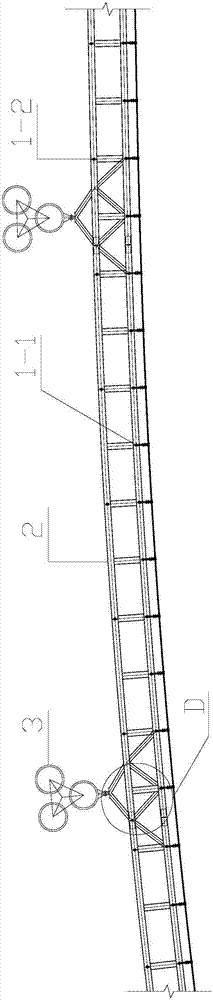

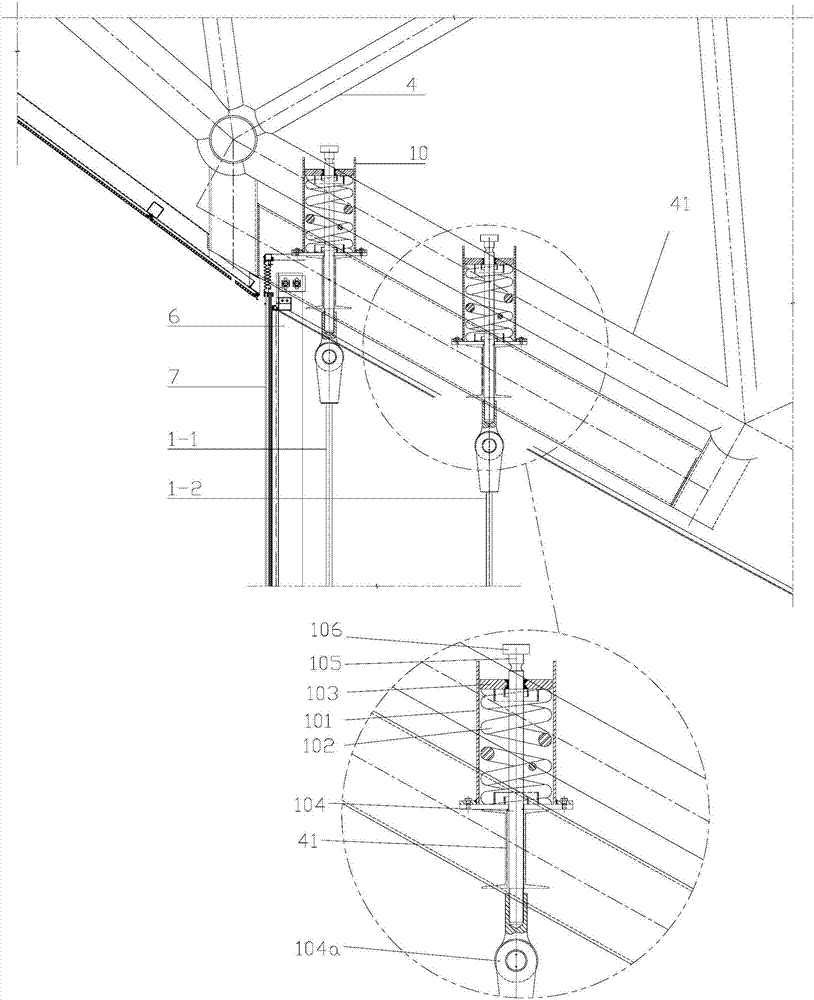

[0051] Such as figure 1 with figure 2 As shown, it is an embodiment of the supporting steel structure for the curved outer curtain wall with spring suspension rods provided by the present invention, including spring suspension rods 1 and horizontal steel pipe trusses 2, and several horizontal steel pipe trusses 2 simulate the level of the curtain wall through stretch bending. The curved surface in the direction is hingedly set on the main structure, specifically, set on the steel column 3 of the main body. Several suspenders 1 with springs are divided into two groups, respectively arranged along the outer edge and inner edge of the horizontal steel pipe truss 2, one group is arranged on the front side of the outer edge of the horizontal steel pipe truss 2 as the front end suspender 1-1, and the other One group is arranged on the rear side of the inner edge of the horizontal steel pipe truss 2 as the rear end suspenders 1-2.

[0052] The structure of the front boom and the r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com