Unloading device used for steel structure support and unloading method thereof

A technology of unloading device and steel structure, which is applied in building structure, processing of building materials, construction, etc. It can solve problems such as small unloading space, complex sand box structure, and dangerous brackets, so as to prevent excessive force , Precisely adjust the elevation and save construction cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

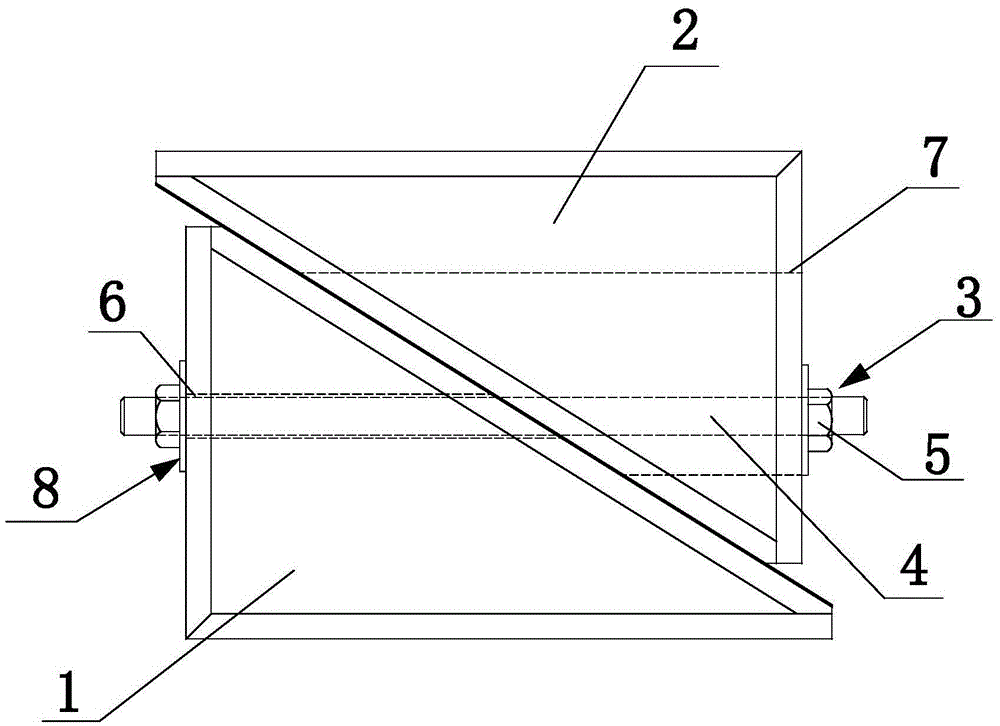

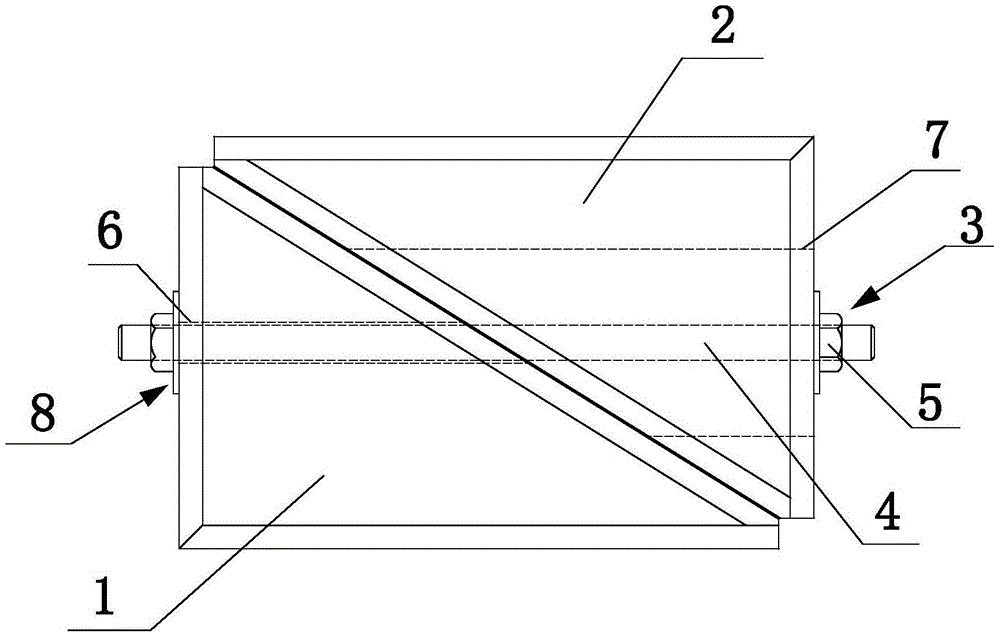

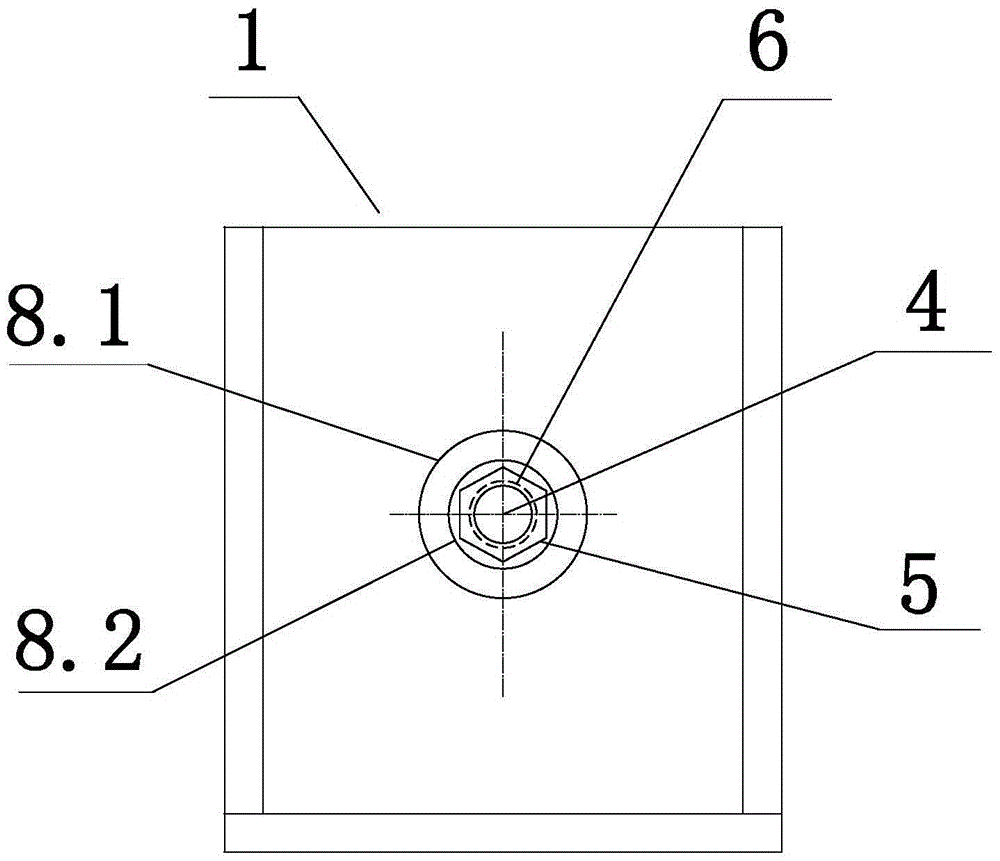

[0024] Such as figure 1 An unloading device for a steel structure support shown in , including a lower wedge 1, an upper wedge 2 that fits on the wedge surface of the lower wedge 1, and an upper wedge 2 for adjusting the The adjustment assembly 3 whose inclination direction slides relative to the lower wedge block 1, the inclined wedge surface of the lower wedge block 1 and the upper wedge block 2 have the same inclination angle, and the inclined wedge surfaces of the two are arranged in close contact, the lower wedge block 1 and the upper wedge block 2 The upper wedge block 2 is detachably connected together through the adjustment assembly 3, and its whole can withstand a vertical load within 800kN. As a preferred solution, the inclination angles of the wedge surfaces of the lower wedge block 1 and the upper wedge block 2 are both 3...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com