Hollow glass with controllable dimming structure

A controllable, hollow technology, applied in parallel glass structures, optics, building components, etc., can solve problems such as unfavorable environmental protection, dazzling and strong light, and inability to change the direction of light irradiation, saving energy, low manufacturing costs, and solving problems. Sunshine effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

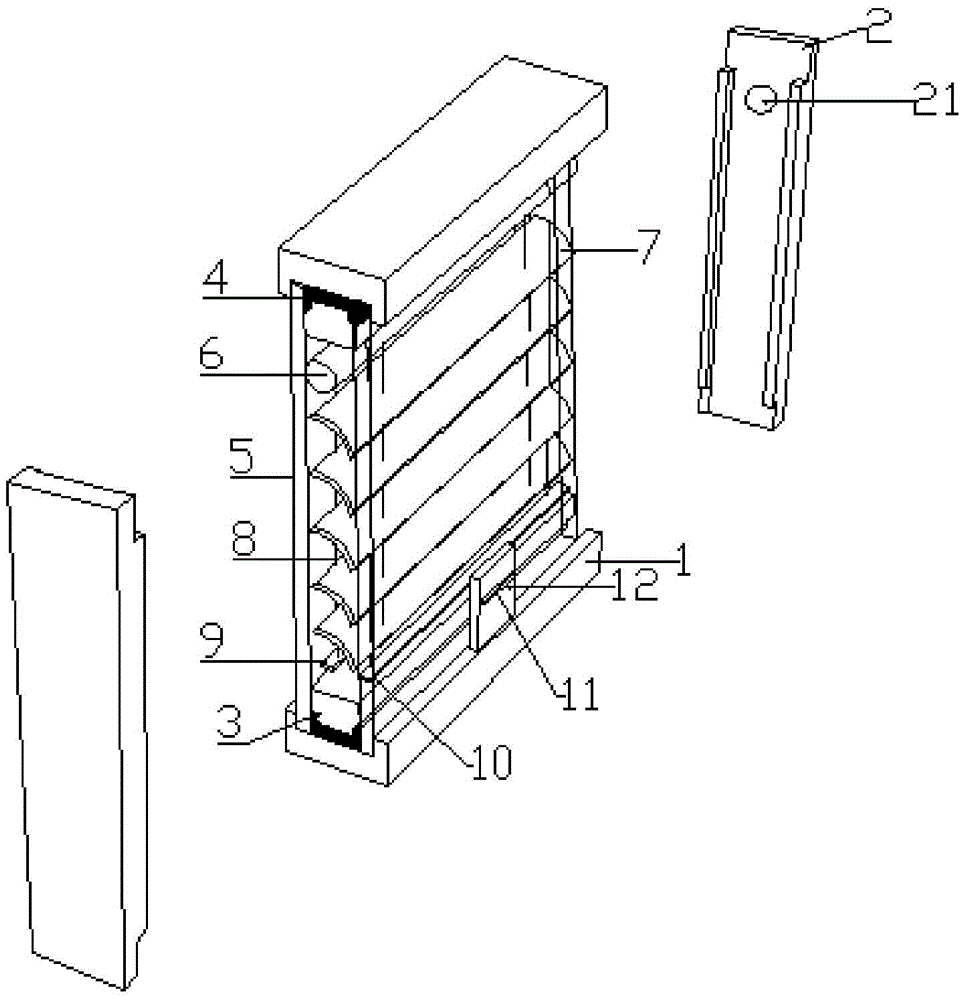

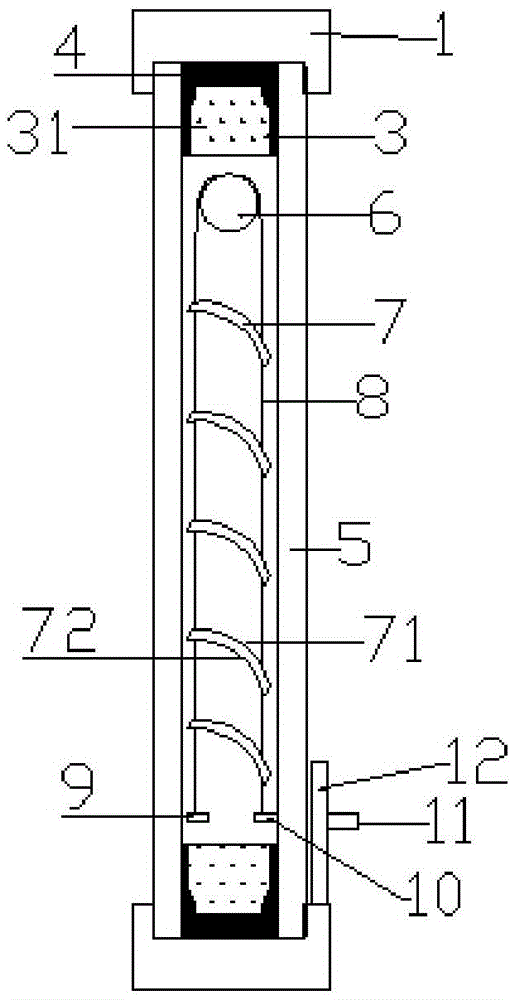

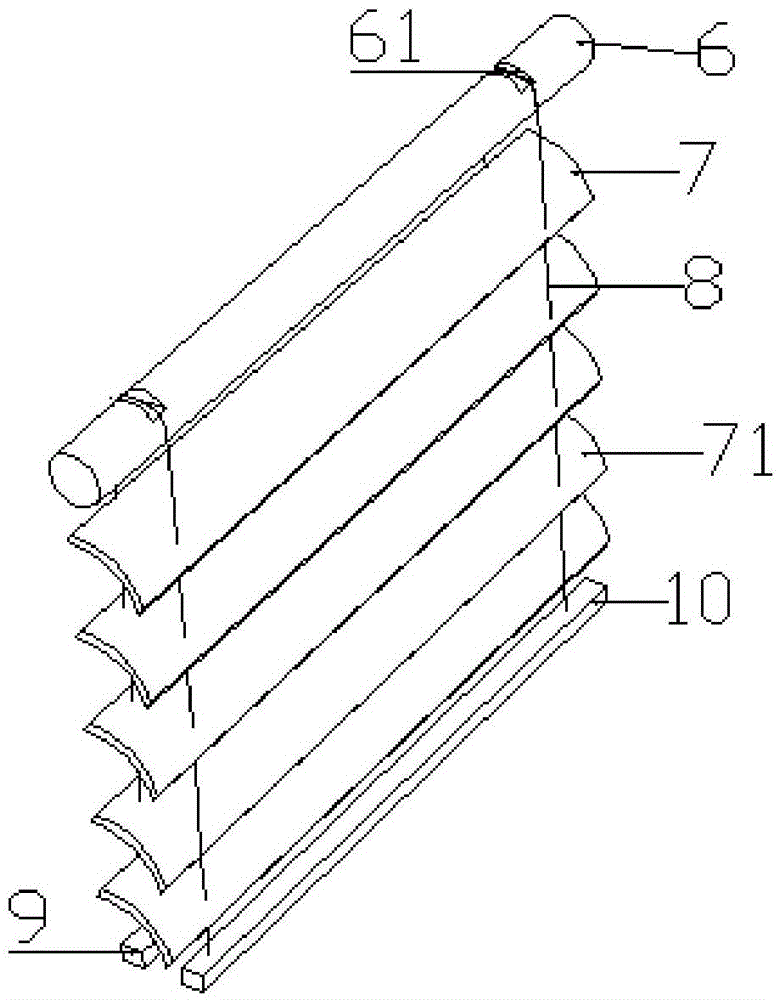

[0041] Such as figure 1As shown, a hollow glass with a controllable dimming structure includes a horizontal window frame 1, a vertical window frame 2 and a hollow glass sheet 5, and the hollow glass sheet 5 is selected from tempered glass, and the hollow glass sheet 5 is sandwiched between the horizontal window frame 1 and the longitudinal window frame 2, the hollow glass sheet 5 is provided with a spacer 3 and a sealant 4, and the hollow glass sheet 5 and the spacer 3 are sealed Glue 4 forms a hollow cavity, and the sealant 4 is a double-channel sealant comprising one sealant and two sealants, the first sealant is hot-melt butyl rubber, and the second sealant is silicone Structural glue, the hollow cavity is filled with air, the spacer 3 is a plastic warm edge strip, the spacer 3 is provided with a molecular sieve hollow glass desiccant, and the hollow cavity is provided with a controllable dimming structure, the controllable dimming structure includes a traction shaft 6 and...

Embodiment 2

[0044] Figure 7 Be another embodiment of the present invention, in the present embodiment, the basic structure of the present invention is the same as embodiment 1, the difference between embodiment 2 and embodiment 1 is that described spacer bar 3 selects stainless steel bar for use, so Molecular sieve hollow glass desiccant is provided in the stainless steel bar, argon gas is filled in the hollow cavity, coated glass is used for the hollow glass sheet 5, and the specular reflection surface 71 and the diffuse reflection surface 72 of the dimming panel 7 are are flat.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com