Full-hydraulic wheel type integrated drilling machine

A fully hydraulic and drilling rig technology, applied in drilling equipment, earthwork drilling, drilling equipment and methods, etc., to achieve the effects of energy saving, dust avoidance and flexible operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0043] The present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

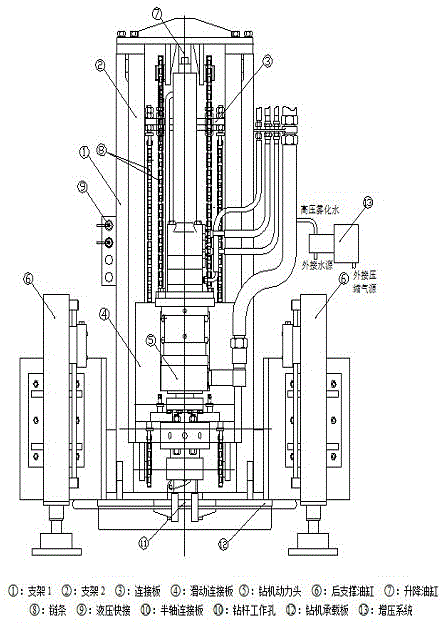

[0044] exist figure 1In , it shows the installation connection and working principle relationship of each component after the drilling rig is converted to a tractor. The entire frame is fixedly installed on the drilling rig bearing plate (12), and the drilling frame has two sets of brackets: bracket 1 (1) and bracket 2 (2). Composition, the sliding connecting plate (4) is welded and fixed to the bracket 2 (2), the drill power head (5) is fixedly connected to the sliding connecting plate (4), and the drill pipe works through the drill pipe opened at the rear of the drilling rig bearing plate (12) Hole (11) works. The lifting cylinder (7) is fixed on the bracket 2 (2), thus forming a linked whole. Through the work of the lifting cylinder (7), the bracket 2 (2) is driven to slide up and down, and the bracket 2 (2) drives the sliding connecting ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com