DIY 3D printer for fruit iced desserts

A 3D printer, freezing point technology, applied in the fields of frozen desserts, food science, applications, etc., can solve the problems of unseen ice products, cumbersome equipment, long time, etc., and achieves convenient offline operation, simple button-type operation, and convenient operation. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

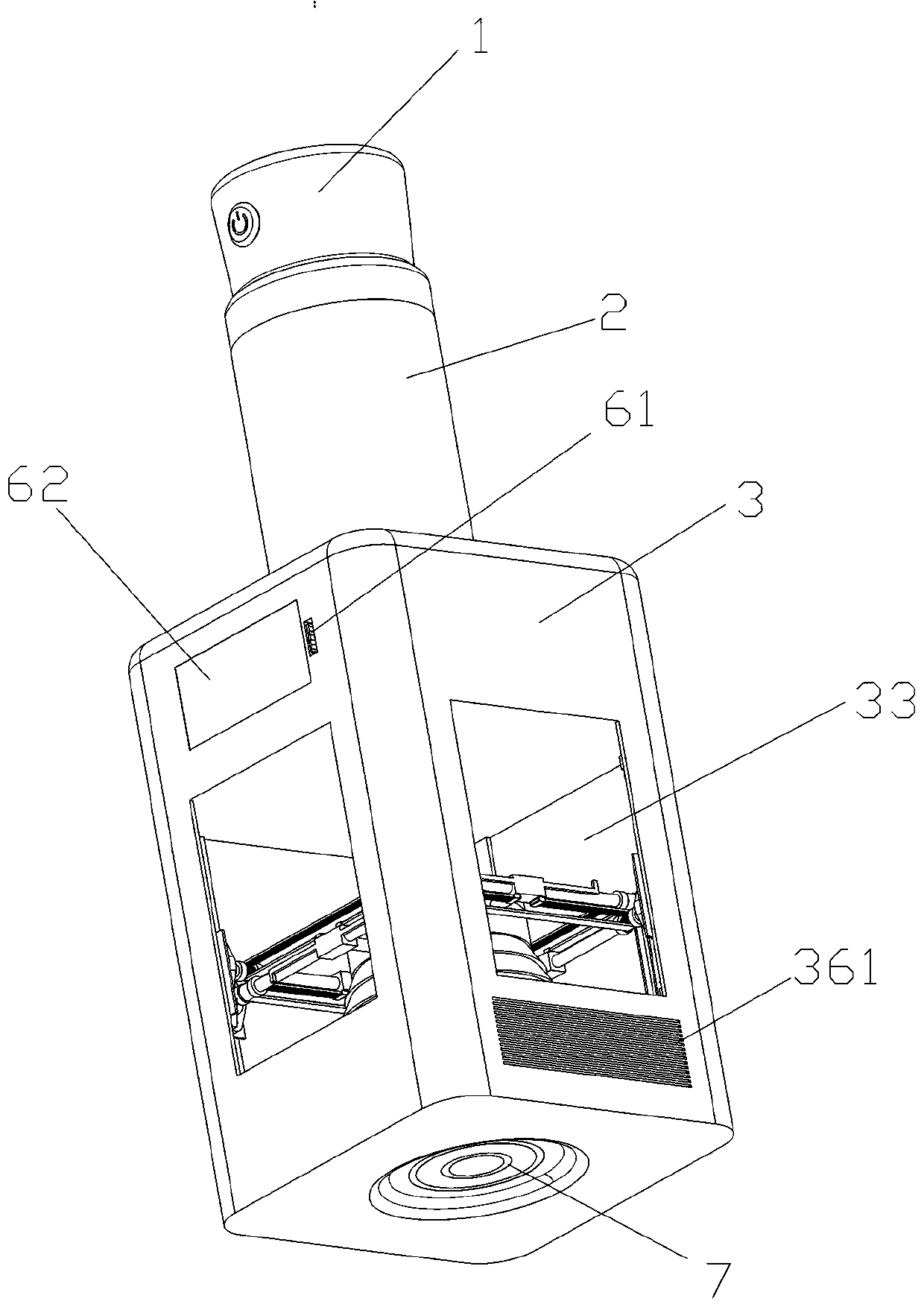

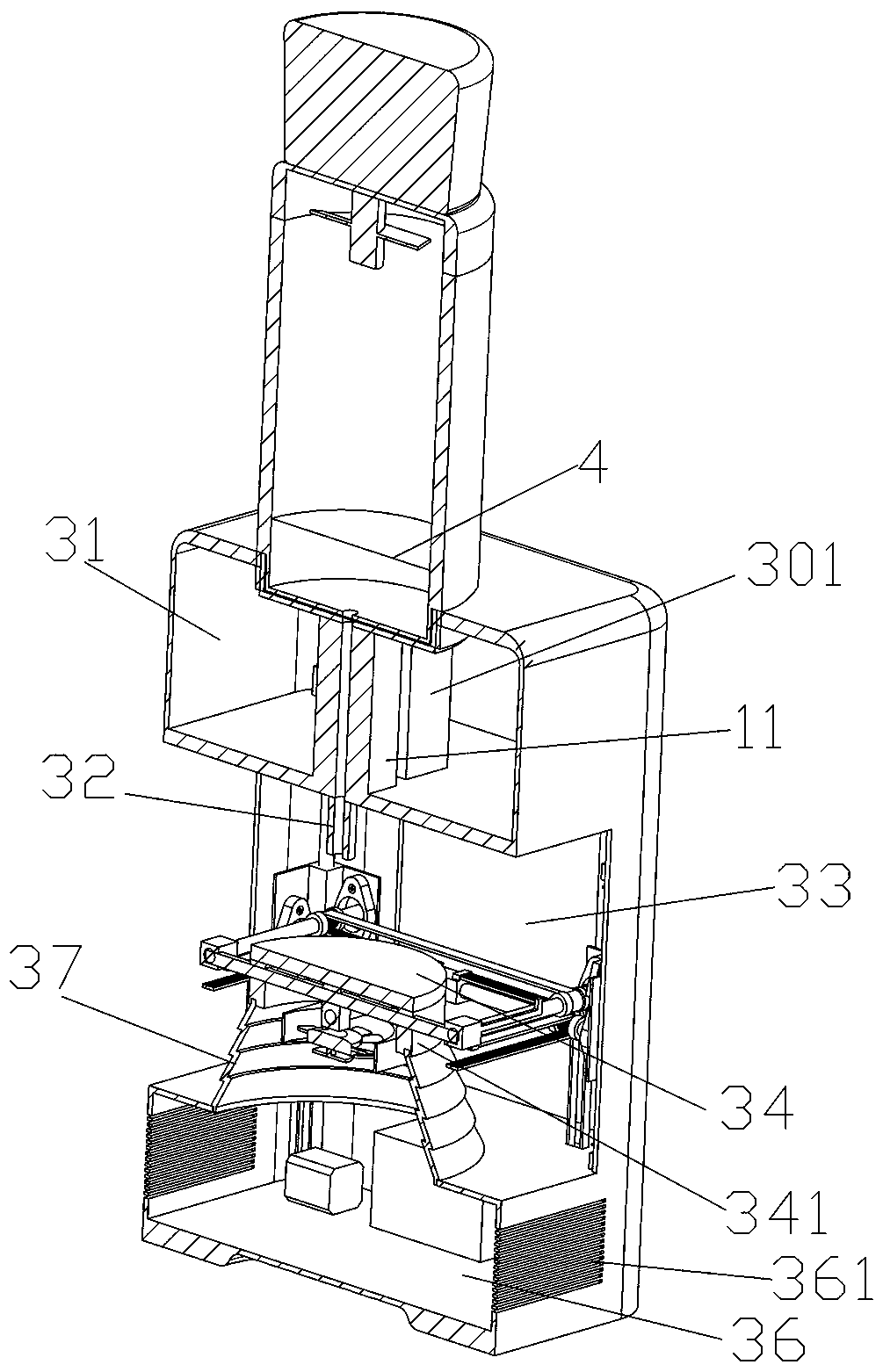

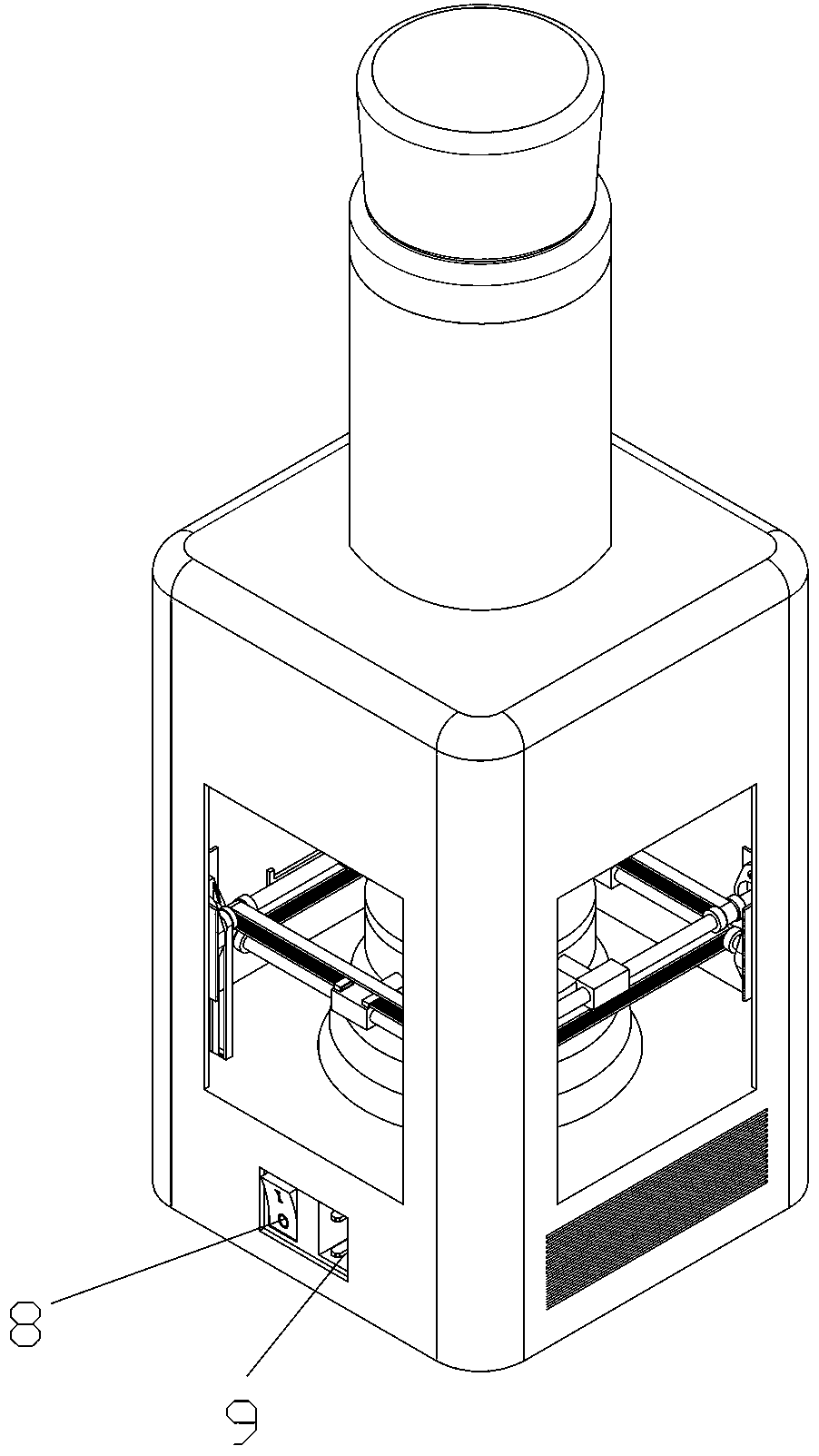

[0034] A DIY fruit freezing point 3D printer, comprising a fruit juicer agitator 1, a double-opened container cup 2 with openings connected to both ends of the fruit juicer agitator, and a freezing point printer 3, the double-opened container cup or the double-opened container cup A filter sieve 4 is provided between the open container cup and the freezing point printer.

[0035] The freezing point printer includes a buffer cavity 31 at the top with a delivery pipeline column 11 connected to the bottom juice outlet of the fruit juicer agitator, an outlet connected to the bottom of the buffer cavity and communicating with the lower port of the delivery pipeline column 11. The liquid pipe 32, the 3D printing chamber 33 connected to the bottom of the buffer chamber, the movable printing table assembly and the heat dissipation structure at the bottom of the printing table assembly located in the 3D printing chamber; The micro-air pump 301 of the open container cup is used to extru...

Embodiment 2

[0042] The difference from the above embodiments is that the moving device includes a vertical moving structure that enables the printing table assembly to move in the direction of gravity and a horizontal moving structure that is arranged on the vertical moving structure to enable the printing table assembly to move horizontally, so The horizontal moving structure includes a vertical structure and a horizontal structure; the vertical moving structure includes a plurality of vertical screw rods 51 vertically installed in the 3D printing chamber, and the horizontal moving structure includes a set A horizontal frame 52 on the screw mandrel, a horizontal rod 53 connected between two adjacent horizontal frames, and a mobile frame 54 connected between the underframe cover and the horizontal rod.

[0043] The horizontal screw rods are horizontal screw rods, and the horizontal screw rods include a pair of parallel longitudinal screw rod groups and a pair of parallel horizontal screw r...

Embodiment 3

[0045] The difference from the above embodiment is that the horizontal sliding rod is a horizontal sliding rod, and the horizontal sliding rod includes a pair of parallel longitudinal sliding rod groups and a pair of parallel horizontal sliding rod groups, and the moving frame rod The follower 541 provided at the end and having a socket hole slidingly socketed with the horizontal sliding rod is slidably connected with the horizontal sliding rod. Both ends of each horizontal sliding rod are provided with The toothed belt on the inside is connected to the gear section 531 of the horizontal slide bar of the same group, and the two free ends of each belt are connected to the nearby follower of the horizontal slide bar parallel to the belt, so that the rotation of the belt drives The follower moves. The above-mentioned structure drives the follower on the horizontal sliding bar in another group to slide along the horizontal sliding bar through the movement of the belt, and then dri...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com