Oil filter for automobile

An oil filter and automobile technology, which is applied in the installation/connection of lubricant purification devices, lubricating parts, pressure lubricants, etc. Avoid reverse flow, improve stirring effect, improve filtering effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] It should be noted that, in the case of no conflict, the embodiments in the present application and the features in the embodiments can be combined with each other; the present invention will be described in detail below with reference to the accompanying drawings and in combination with the embodiments.

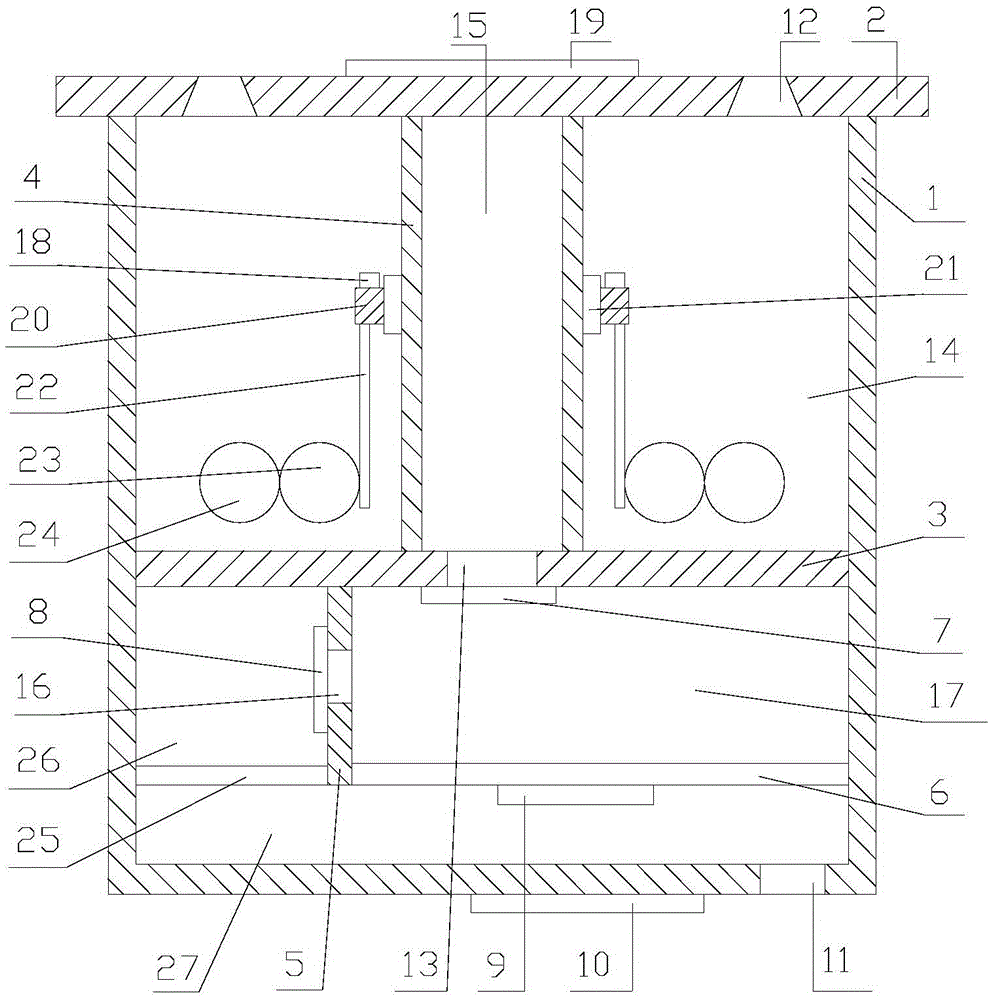

[0027] refer to figure 1 :

[0028] An automobile oil filter proposed by the present invention includes a housing 1, an end cover 2, a first partition 3, a first filter element 4, a second partition 5, an elastic sheet 6, a first one-way membrane 7, The second one-way film 8, the first magnetostrictive film 9, the first coil 10, the cleaning plate 20, the second magnetostrictive film 18, the second coil 19, the bristles 21, the rack 22, the first turntable 23, the second Two rotary discs 24, the second filter element 25.

[0029] The housing 1 is provided with an oil outlet 11 .

[0030] The end cover 2 is detachably mounted on the housing 1, and the end cover 2 is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com