Device and method for reducing temperature error of test adopting electric field fingerprint method

A technology for testing temperature and electric field fingerprints, which is applied to pipeline systems, mechanical equipment, gas/liquid distribution and storage, etc. It can solve the problems of corrosion monitoring results, unsatisfactory reference results, and untimely response of reference plate temperature. Achieve accurate results, prevent danger, and calculate precise effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0051] Figure 1~4 It is the best embodiment of the present invention, below in conjunction with attached Figure 1~4 The present invention will be further described.

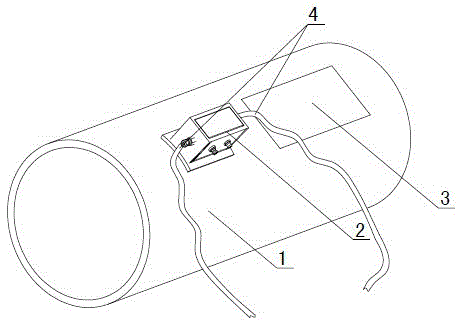

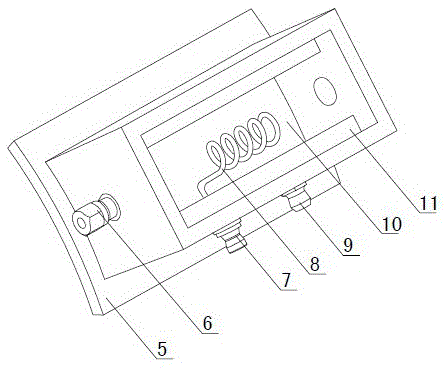

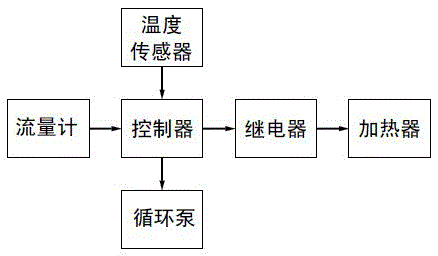

[0052] Such as figure 1 As shown, a device for reducing the temperature error of the electric field fingerprint method test includes a pipeline to be tested 1 and a voltage acquisition area 3 arranged on the pipeline to be tested 1, and an acquisition matrix composed of several capture electrodes is arranged in the voltage acquisition area (not shown in the figure), the acquisition matrix has the same row spacing and column spacing. An operation compensation device 2 is arranged on one side of the voltage collection area 3, and the operation compensation device 2 is arranged close to the pipeline 1 to be tested. The two ends of the operation compensation device 2 respectively lead out the medium circulation pipeline 4, and the medium circulation pipeline 4 is respectively connected with the inlet and outlet ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com