Novel LED heat dissipation lamp

A technology of LED light source and LED driver board, applied in lighting and heating equipment, cooling/heating devices of lighting devices, lighting devices, etc., can solve problems such as potential safety hazards, high heat generation, and failure of LED lights to reach predetermined brightness, etc., to achieve Guarantee the performance and service life, and enhance the effect of heat dissipation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

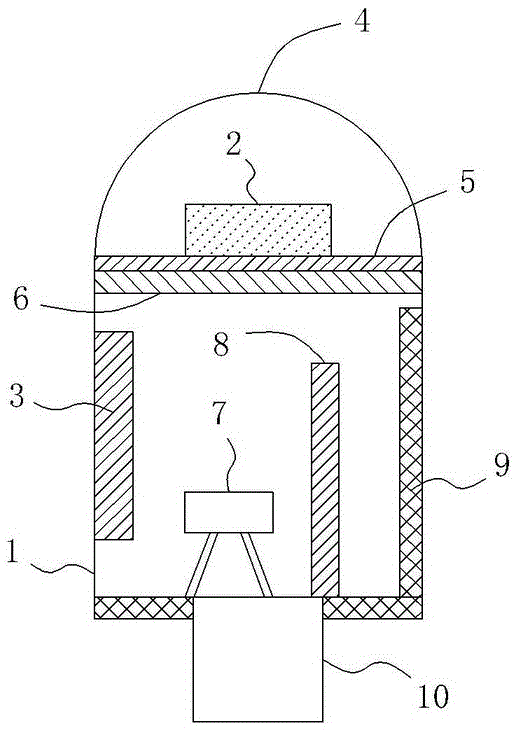

[0016] Such as figure 1 As shown, a new type of LED heat dissipation lamp includes a housing 1, and an LED light source 2 and an LED driver board 3 are respectively provided in the housing 1. The LED light source 2 is arranged on the top of the housing 1 and above the LED light source 2. There is also a condenser cover 4 connected to the housing 1, a heat conduction layer 5 is provided below the LED light source 2, a heat sink 6 is also provided below the heat conduction layer 5, and the LED driver board 3 is vertically arranged on the heat sink 6 and at the same time at the left end of the housing 1;

[0017] The right side of the LED driver board 3 is also provided with a heat dissipation fan 7, and the right side of the heat dissipation fan 7 is also provided with a vertically arranged guide plate 8, and a plurality of cooling fans are evenly distributed on the right side and the bottom of the housing 1. hole (not shown in the figure), and the right side and bottom end of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com