Turntable type automatic slag-crushing combustion machine

A rotary disc type, burner technology, applied in combustion methods, combustion equipment, combustion of solid fuels, etc., can solve the problems of blocking and sealing, low efficiency, labor and time consuming, etc., to ensure quality, prevent slagging, and prolong use. effect of life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

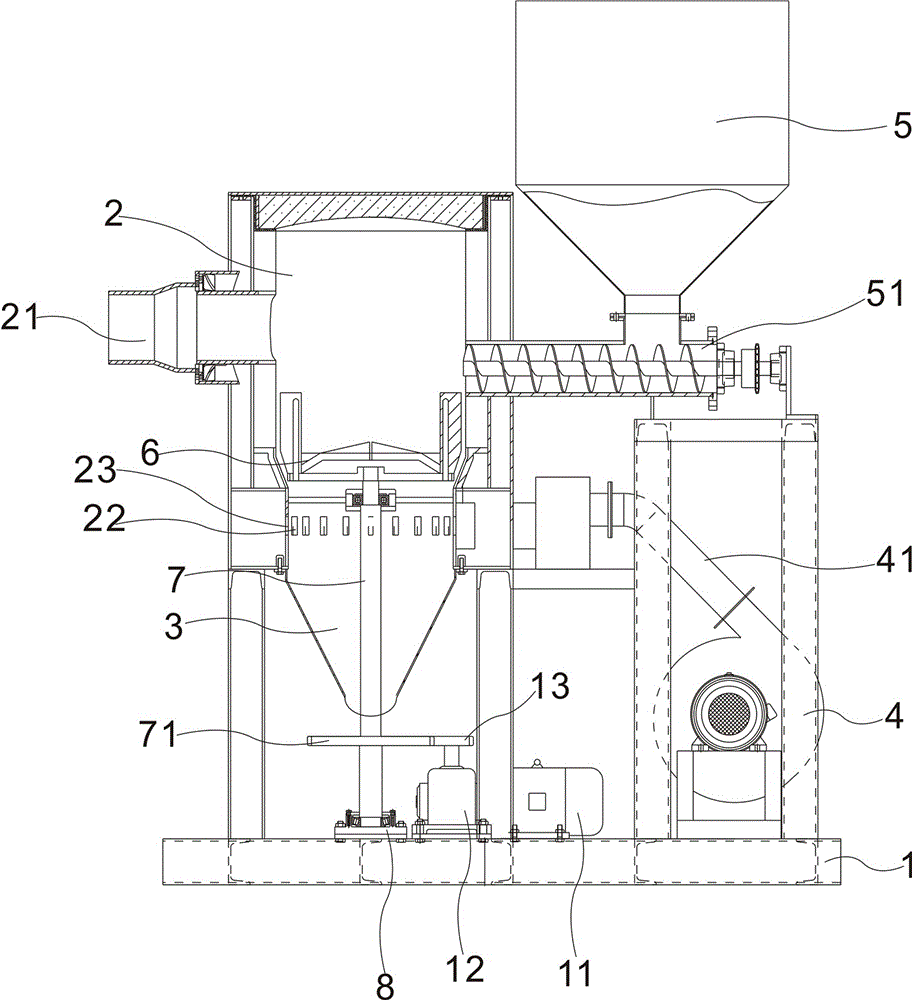

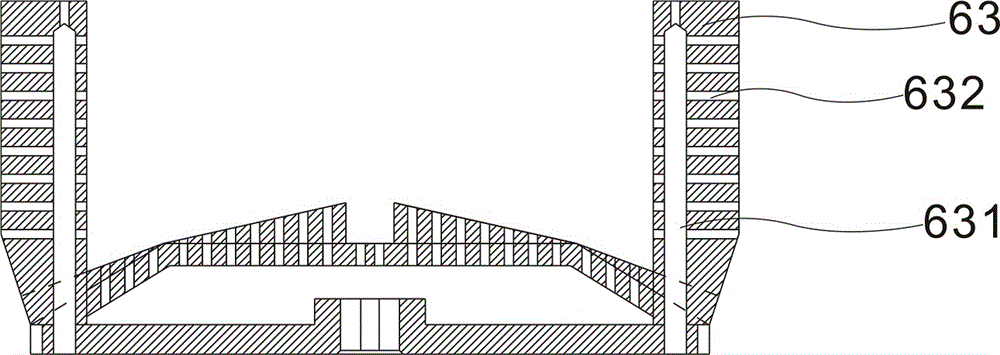

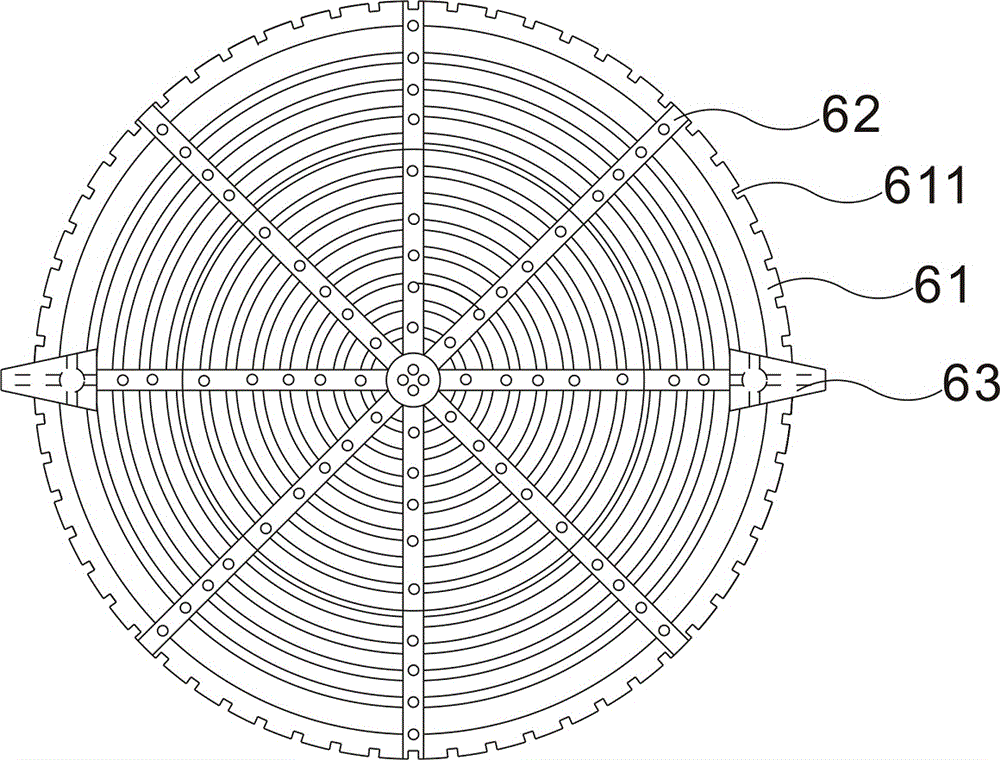

[0013] Such as figure 1 As shown, the rotary table type automatic slag burner includes a frame 1, and a furnace, an air supply device, a feeding device, and a slag removal device arranged on the frame 1. The furnace is composed of an upper cylindrical combustion chamber. The chamber 2 and the lower conical blanking chamber 3 are connected to form, the combustion chamber 2 is provided with a flame nozzle 21, and the bottom of the blanking chamber 3 is provided with a discharge port, and the air supply device includes a blower fan 4 and an air duct 41, The blower fan 4 is communicated with the combustion chamber 2 through the air duct 41, and the feeding device is composed of a lower hopper 5 connected to a screw feeder 51, and the discharge port of the screw feeder 51 is communicated with the combustion chamber 2, and the described removal The slag device is located in the furnace, and it includes a slag removal tray 6 and a rotating shaft 7. The bottom of the slag removal tray...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com