Calorimetric testing method and device of continuous flow gas-phase reaction technology

The technology of a testing device and a testing method, which is applied in the field of calorimetric testing of a continuous flow gas phase reaction process, can solve problems such as the lack of calorimetric testing of a continuous flow chemical process, improve collection sensitivity, meet measurement accuracy requirements, and solve temperature measurement problems Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

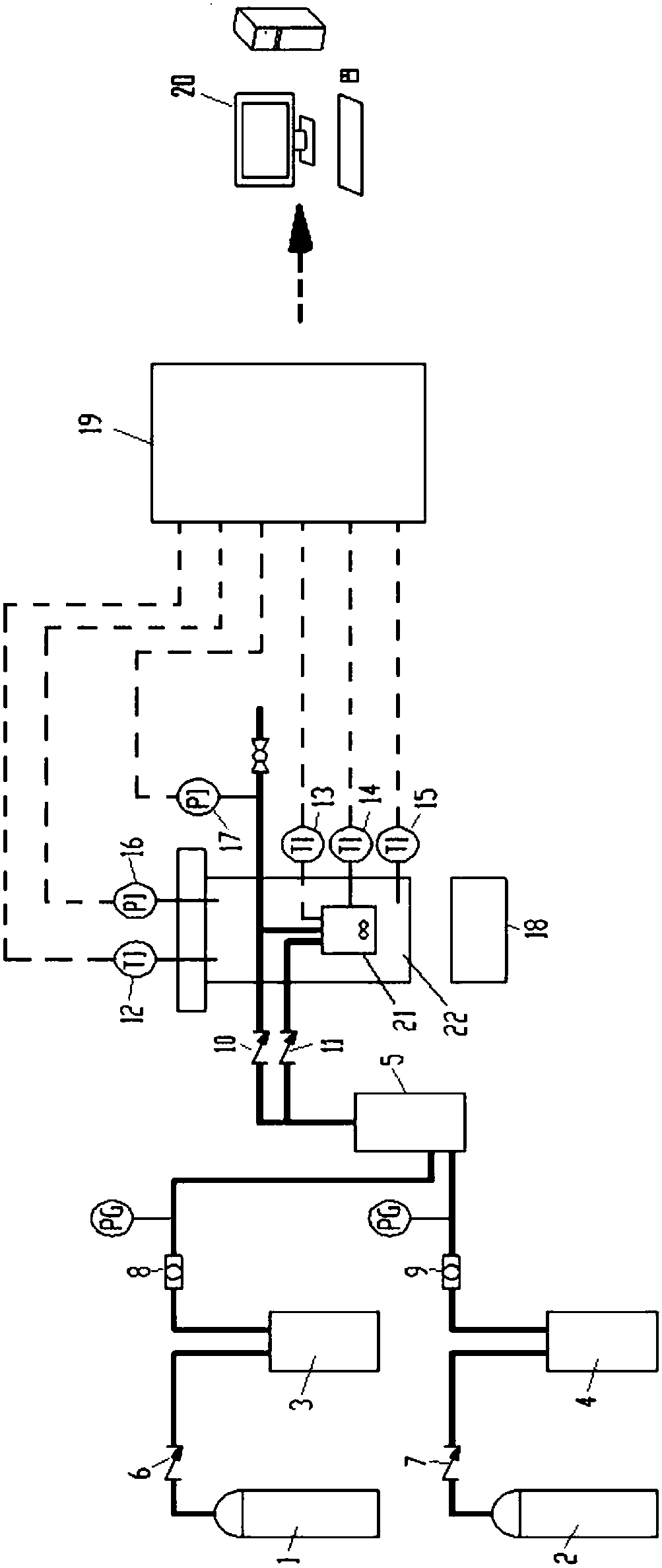

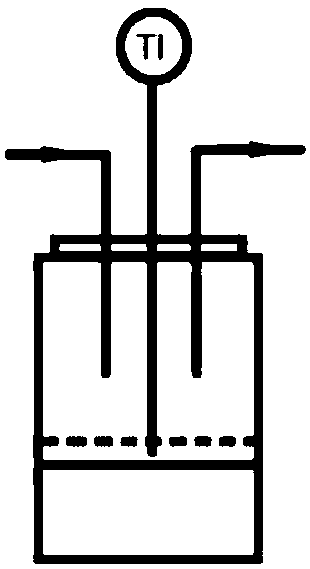

[0042] Such as figure 1 As shown, the present invention includes a reactor 22, a control unit 19, a central control system 20 and a plurality of sensors, wherein the reactor 22 is provided with a reaction test pool 21, and the reactor 22 and the reaction test pool 21 are both airtight , the reactor 22 provides a sealed reaction environment for the reaction test pool 21, and the multiple sensors include sensors for monitoring the internal temperature and pressure of the reactor 22 and sensors for monitoring the reaction test pool. 21 internal temperature and pressure sensors, each sensor is connected to the control unit 19, the control unit 19 is connected to the central control system 20, and the reaction test pool 21 is provided with independent feed channels and outlets. The feed channel, and both the feed channel and the discharge channel extend to the outside of the reactor 22, and the feed channel is connected with the feed system. Both the reactor 22 and the reaction te...

Embodiment 2

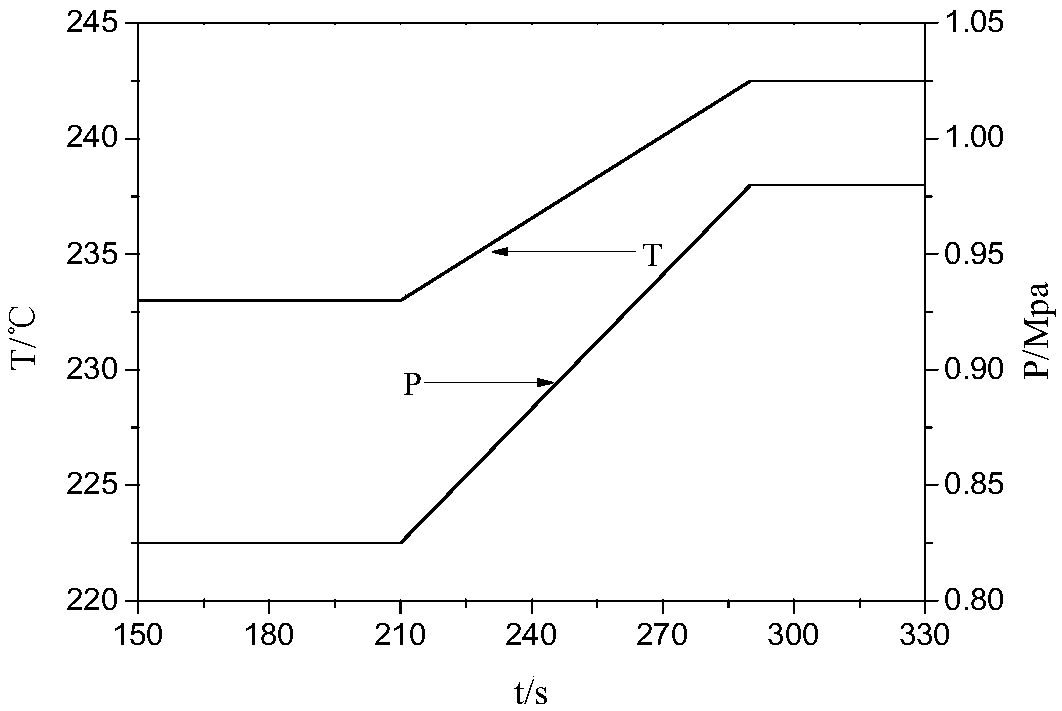

[0062] In this example, the process of trichlorethylene and hydrogen fluoride to generate 1,1,1-trifluoro-2-chloroethane through addition and substitution reaction is taken as an example, and the solid catalyst is CrO-Y 2 o 3 . The invented calorimetric test method will be described. The feed molar ratio of chloroalkene and hydrogen fluoride is 1:3.05, the reaction temperature range is 220-300°C, the material residence time is 30-90s, and the reaction pressure is 0.8-1.05Mpa.

[0063] experiment procedure:

[0064]1) Air tightness test of the reaction system. Connect the reaction system to the nitrogen cylinder, feed nitrogen into the system through the pressure reducing valve, the nitrogen pressure reaches 2.0MPa, keep the pressure for 1 hour, during the pressure keeping process, the pressure drop of the reactor system is less than 0.01bar / min, it is considered that there is no leakage in the reaction system , the end of holding pressure;

[0065] 2) Pressure relief. Af...

Embodiment 3

[0082] This embodiment takes 1,1,2-trifluoro-1,2,2-trichloroethane and hydrogen as an example to generate chlorotrifluoroethylene through catalytic reaction, and selects copper, lanthanum and activated carbon supported solid catalyst (copper is the main active component, lanthanum is the modifier component, and activated carbon is the carrier). The invented calorimetric test method will be described. The feed molar ratio of 1,1,2-trifluoro-1,2,2-trichloroethane and hydrogen is 1:3, the reaction temperature range is 130-180°C, and the material residence time is 30-40s. The pressure is 0.1-0.15Mpa.

[0083] Adopt the device described in embodiment 1 to carry out the measurement that above-mentioned reaction is carried out calorimetry, test procedure is identical, derives experimental data through IQ, analysis experimental result is as follows Figure 4 According to the data analysis, 1,1,2-trifluoro-1,2,2-trichloroethane reacts with hydrogen to generate chlorotrifluoroethylene...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com