Method for determining cut tobacco composition based on near infrared spectrum

A near-infrared spectroscopy and measurement method technology is applied in the field of tobacco composition determination based on near-infrared spectroscopy.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

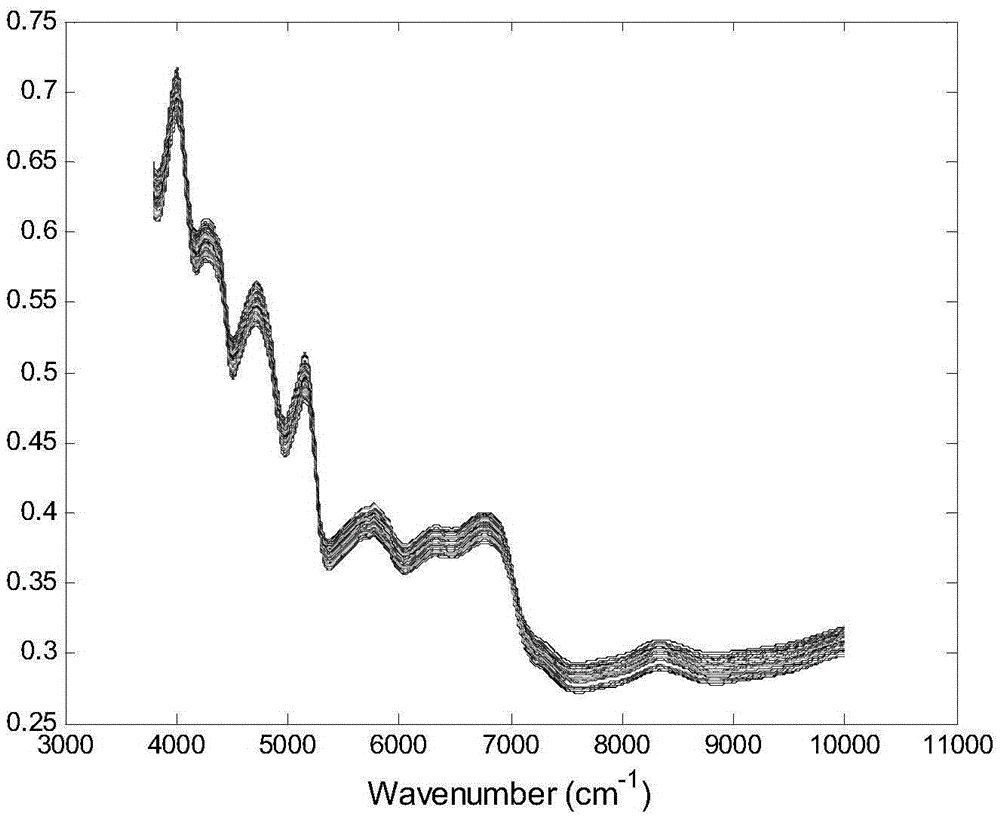

[0032] The method for determining the composition of shredded tobacco based on near-infrared spectroscopy of the present invention will be described in detail below in conjunction with the accompanying drawings.

[0033] (1) Collect flue-cured tobacco shreds, expanded stems, expanded shredded leaves and tobacco flakes, and prepare them into powder according to the tobacco industry standard "YC / T31-1996 Tobacco and Tobacco Products Sample Preparation and Moisture Determination Oven Method" sample.

[0034] (2) According to the blending ratio shown in Table 1, the flue-cured tobacco shred powder, expanded cut stem powder, expanded shredded leaf powder and tobacco flake powder were evenly mixed to prepare corresponding powdered cut tobacco samples.

[0035] Table 1

[0036]

[0037]

[0038] A total of 32 kinds of cut tobacco samples with different blending ratios were prepared, and two samples of each blending ratio of shredded tobacco samples were prepared independently,...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Granularity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com