Online detection method for performance of oil displacement foams

A detection method and foam technology, applied in the direction of measuring devices, material analysis through optical means, instruments, etc., can solve the problems of complex operation, unfavorable large-scale promotion and application, and inability to guarantee, and achieve the effect of simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

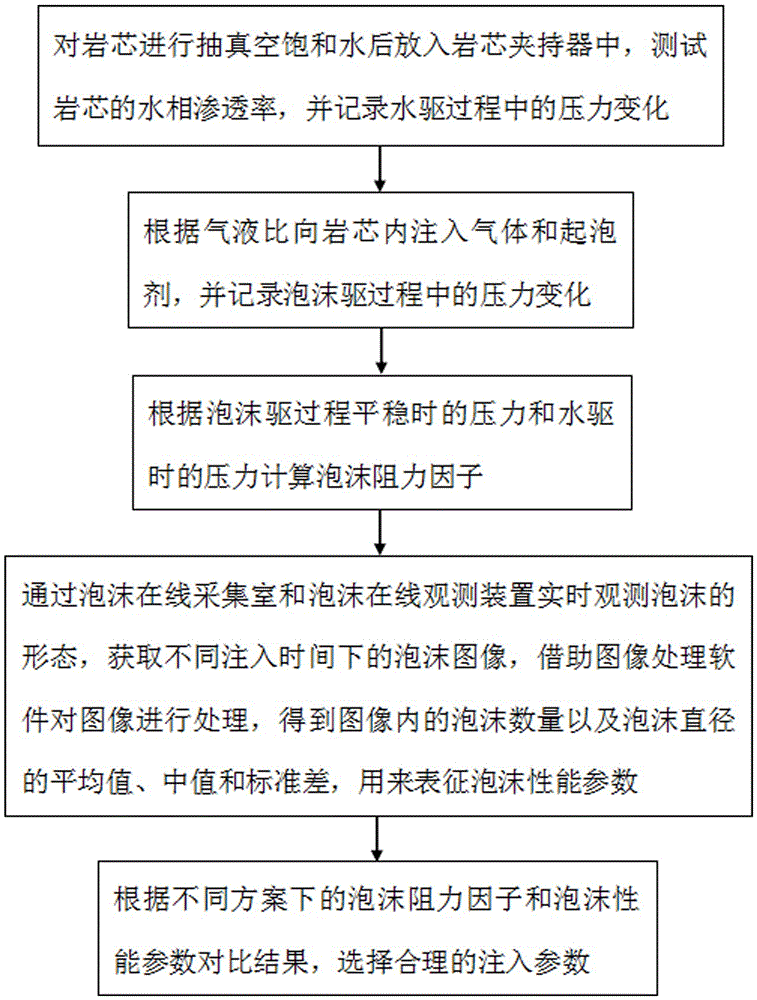

[0042] Such as figure 1 As shown, according to an embodiment of the on-line detection method of the oil displacement foam performance of the present invention, the following steps may be included in sequence:

[0043] Step 1: Vacuumize the core and saturate it with water, put it into the core holder, test the water phase permeability of the core, and record the pressure change during the water flooding process;

[0044] Step 2: Inject gas and foaming agent into the core according to the gas-liquid ratio, and record the pressure change during foam flooding;

[0045] Step 3: Calculate the foam resistance factor according to the pressure when the foam flooding process is stable and the pressure during water flooding;

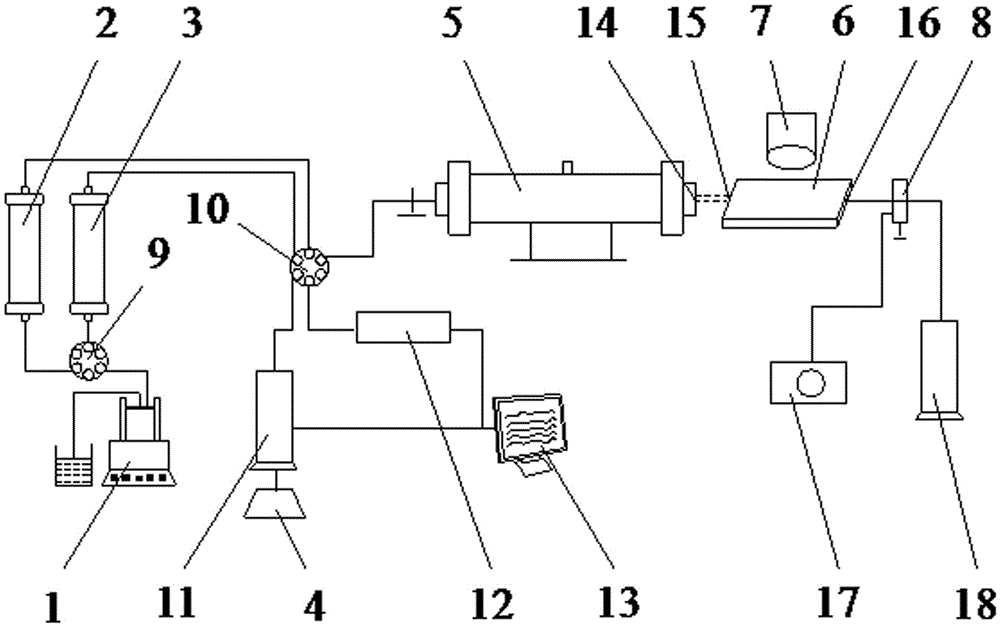

[0046] Step 4: Observe the shape of the foam in real time through the online foam collection room and the online foam observation device, obtain foam images at different injection times, and process the images with the help of image processing software to obtain t...

Embodiment 2

[0059] According to another embodiment of the on-line detection method of the oil displacement foam performance of the present invention, its technology, working principle, on-line detection device adopted and beneficial effect etc. are all the same as embodiment one, the difference is:

[0060] In the on-line detection device of foam performance for oil displacement, a metal pipeline is set between the inlet end of the foam line collection chamber and the outlet end of the core holder, and steel sand is filled inside the metal pipeline. The metal pipeline is very short, only 5mm, which can reduce the flow time of the foam after it leaves the core holder to a certain extent, thereby reducing the experimental error and obtaining the data information of the original foam. The outlet end of the metal pipeline and the core holder and the inlet end of the foam on-line detection device should be well sealed. Steel sand is filled inside the metal pipeline to simulate the existence of...

Embodiment 3

[0062] According to another embodiment of the on-line detection method of the oil-displacement foam performance of the present invention, its process, working principle, on-line detection device adopted and beneficial effect etc. are all the same as Embodiment 1, the difference is: in the oil-displacement foam In the online detection device of performance, the length of the inner space of the foam online collection chamber is 80 mm, the width is 30 mm, and the height is 5 μm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com