a folding terminal

A terminal and bending technology, which is applied in the field of folding terminals, can solve the problems of insufficient pressing support at the bending part, insensitive pressing at the bending part, and large length, and achieve the effect of improving the pressing sensitivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

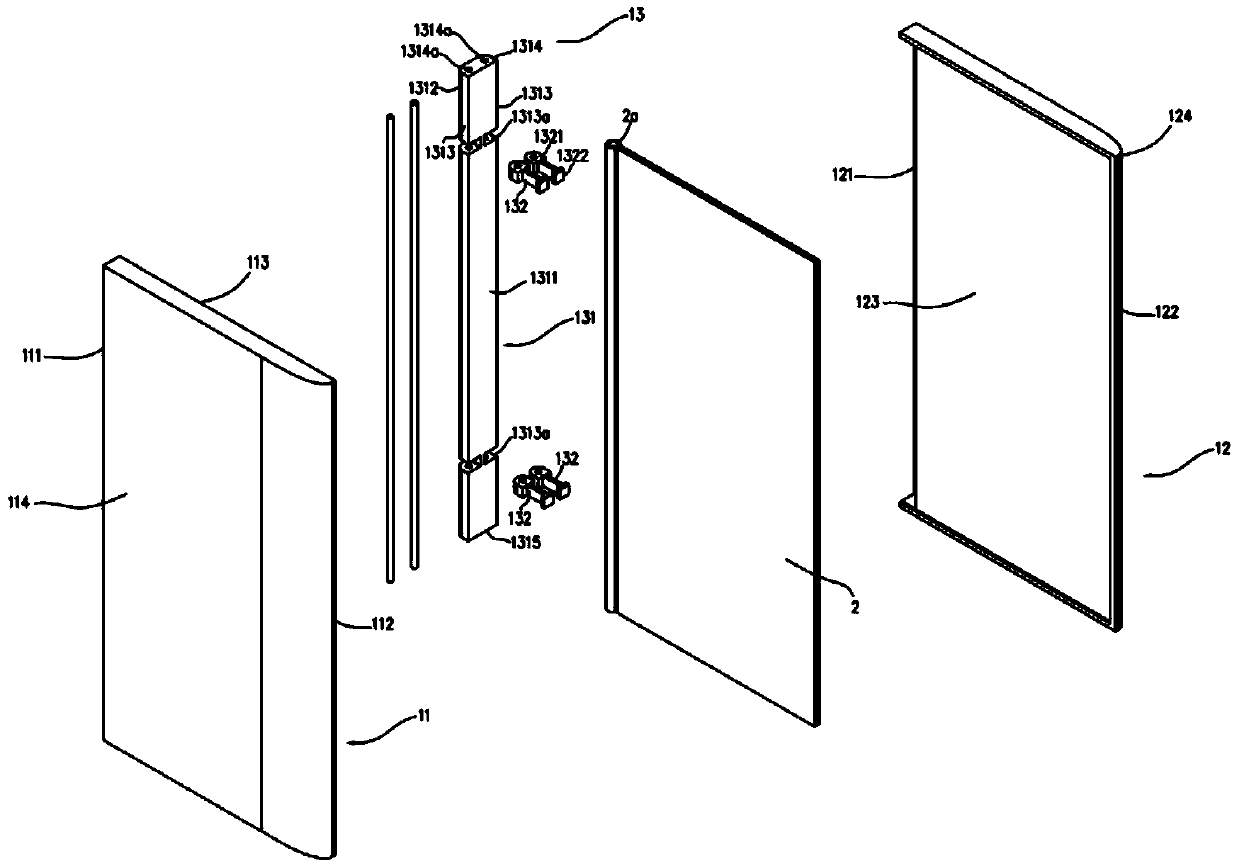

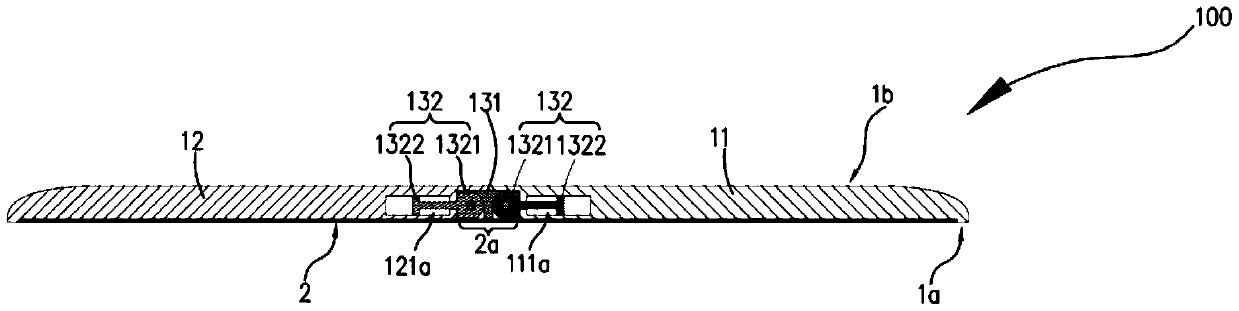

[0031] Please refer to Figure 1 to Figure 5 , a folding terminal 100 provided by the present invention, including a main body 1 and a flexible screen assembly 2,

[0032] The main body 1 includes a first structural member 11, a second structural member 12 and a bending assembly 13; the first structural member 11 and the second structural member 12 are connected together through the bending assembly 13; on the inner surface 1a;

[0033] Wherein, the bending assembly 13 includes a fixing member 131 and a sliding rod 132; by rotating the first end 1321 of the sliding rod 132 to the side wall 1313 of the fixing member 131, the second ends 1322 of the two sliding rods 132 are respectively slidably connected On the first structural member 11 and the second structural member 12, there is a slidable displacement between the fixing member 131 and the first structural member 11 and the second structural member 12; furthermore, as the main body 1 is gradually unfolded, the two The sec...

no. 2 example

[0058] Please refer to Figure 6 , is another foldable terminal 200 provided in the embodiment of the present invention, the first foldable terminal 100 provided in the embodiment of the present invention is basically the same, the difference is that the first sliding cavity 2111a has the same opening as the first sliding cavity 2111a Opposite to the first bottom wall, the second sliding chamber 2121a has a second bottom wall opposite to the opening of the second sliding chamber 2121a, the bending assembly 213 further includes two elastic pieces 214, and one elastic piece 214 is elastically connected to the sliding rod 2132 Between the second end 21322 of the sliding rod 2132 and the first bottom wall; another elastic member 214 is elastically connected between the second end 21322 of the sliding rod 2132 and the second bottom wall.

[0059] In this embodiment, preferably, in order to better provide a deformation space, the elastic member 214 is a spring. Specifically, the el...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com