Automatic button assembling equipment

A technology for assembling equipment and buttons, applied in assembly machines, metal processing equipment, metal processing and other directions, can solve the problems of assembly accuracy affecting sensitivity, plastic parts being easily damaged or scratched, unable to meet production needs, etc., and achieving a simple structure. , avoid damage or scratches, reduce production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] In order to describe the technical content, structural features, and achieved effects of the present invention in detail, the following will be described in detail in conjunction with the embodiments and accompanying drawings.

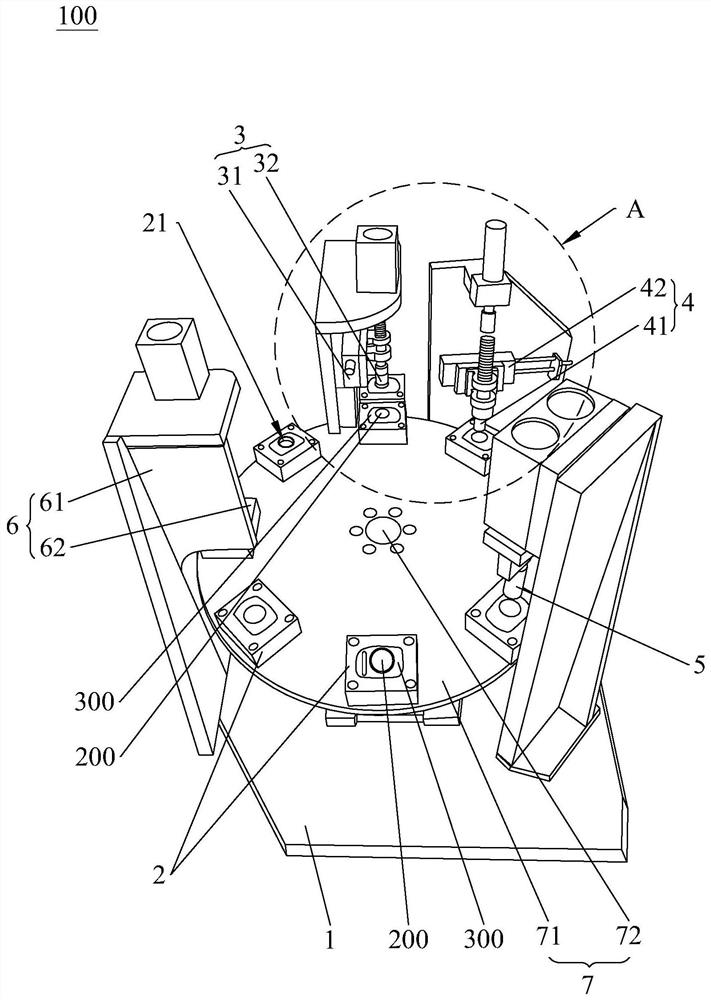

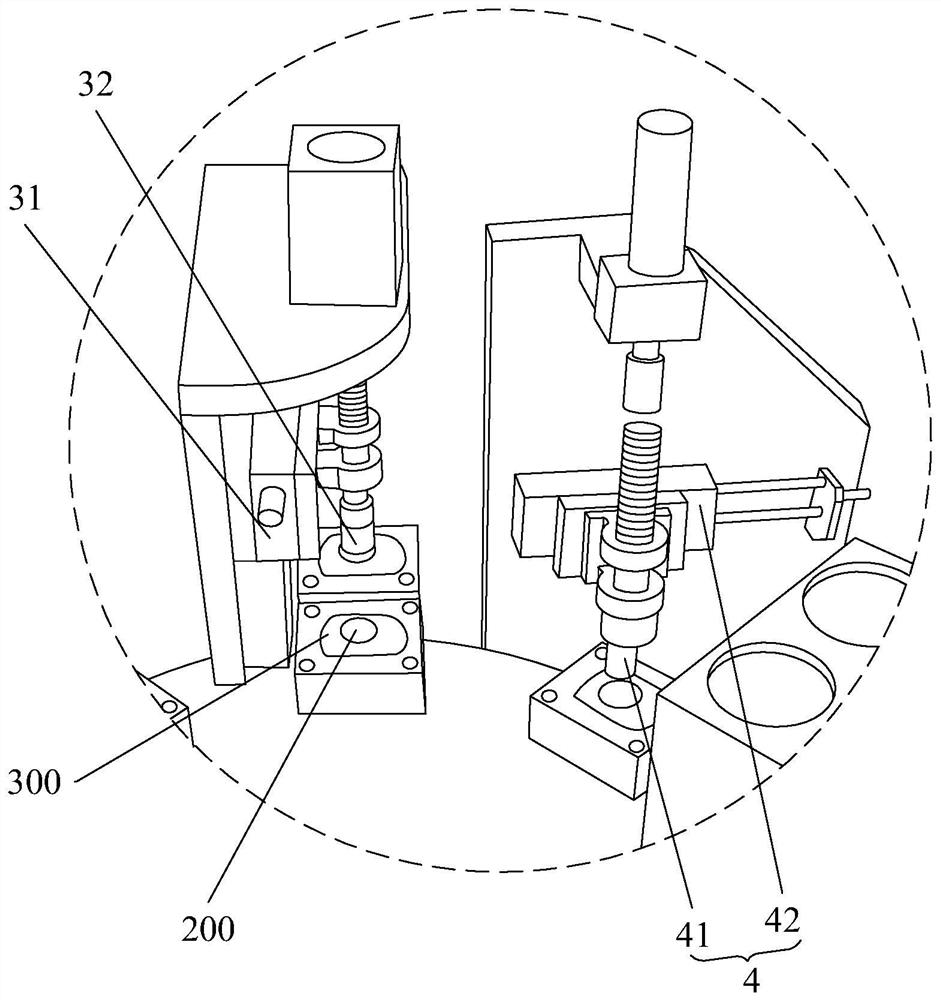

[0019] Such as Figure 1 to Figure 2 As shown, the present invention provides a button automatic assembly equipment 100, which is used to install the button 200 in the base 300. The button automatic assembly equipment 100 includes a frame 1, a carrier 2, a feeding device 3, and a pressing device 4 , a detection device 5, a conveying device 6 and a rotary table 7, the feeding device 3 is used to place the button 200 in the base 300, the pressing device 4 can press the button 200 to the base 300 by air pressure, the detection device 5 For detecting the assembly situation, the rotary table 7 is installed on the frame 1, the carrier 2 is used to carry the base 300, and the carrier 2 is arranged on the rotary table 7, and the carrier 2 has an outer c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com