Conductive foam for fingerprint identification

A conductive foam and fingerprint recognition technology, which is applied in the direction of electrical components, magnetic/electric field shielding, coating, etc., can solve the problems of high resistance and large compression force of conductive foam, and achieve small resistance, low compression force, and good conductivity. The effect of grounding performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

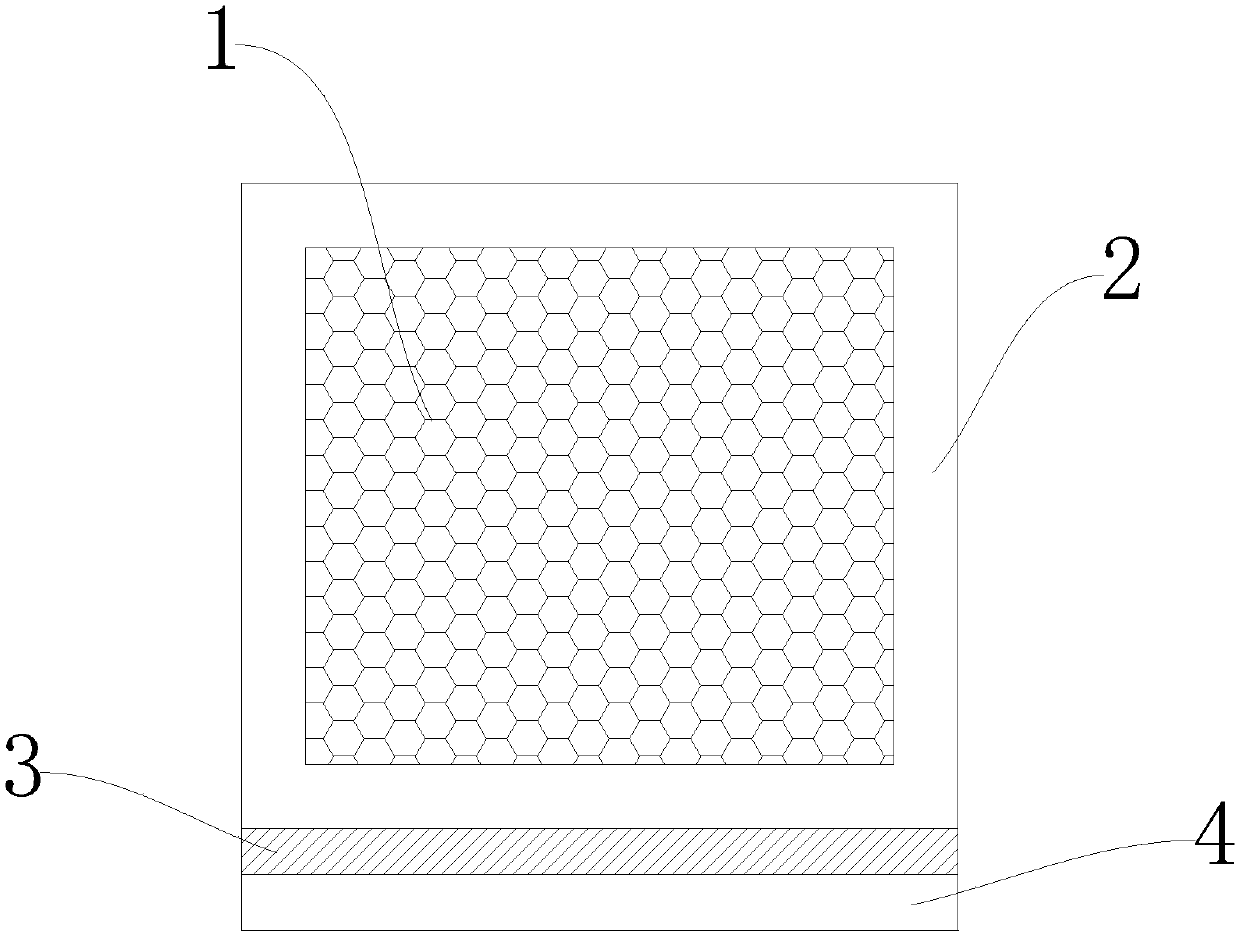

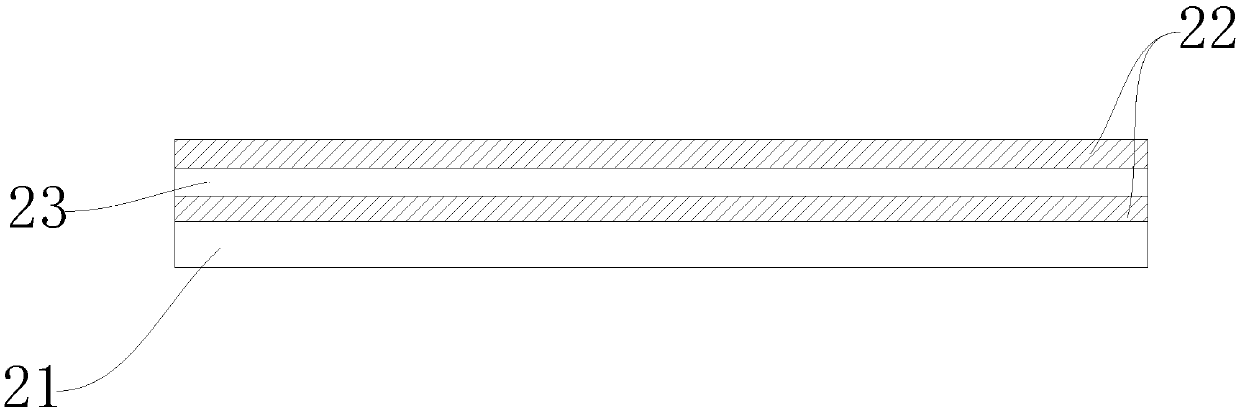

[0016] Such as figure 1 and figure 2 As shown, the conductive foam for fingerprint identification includes foam 1 as the inner core, and the foam 1 is provided with an outer cladding, and the outer cladding is conductive fiber 2 that can completely wrap the foam 1 therein, the Conductive fiber 2 comprises polyester fiber 21 base material, and nickel 22, copper 23, nickel 22 are electroplated successively on described polyester fiber 21 base material so as to form conductive layer, because polyester fiber is provided with conductive layer, thereby can play The function of electromagnetic shielding, in addition, the conductive fiber 2 of this structure has an extremely low grammage and extremely low resistance, and its grammage is 30g / m 2 up to 50g / m 2 , the resistance is less than 0.05ohms / inch 2 The other side of the polyester fiber 21 bas...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| Basis weight | aaaaa | aaaaa |

| tackiness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com