Novel carbon brush structure

A carbon brush, a new type of technology, applied in the direction of collectors, electrical components, rotating collectors, etc., can solve the problems of unfavorable collector ring heat dissipation, different wear speeds of carbon brushes, short-circuit accidents, etc., to facilitate daily inspection and maintenance, Prevents uneven stress and increases service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The specific implementation manners of the present invention will be further described below in conjunction with the accompanying drawings, so as to make the technical solution of the present invention easier to understand and grasp.

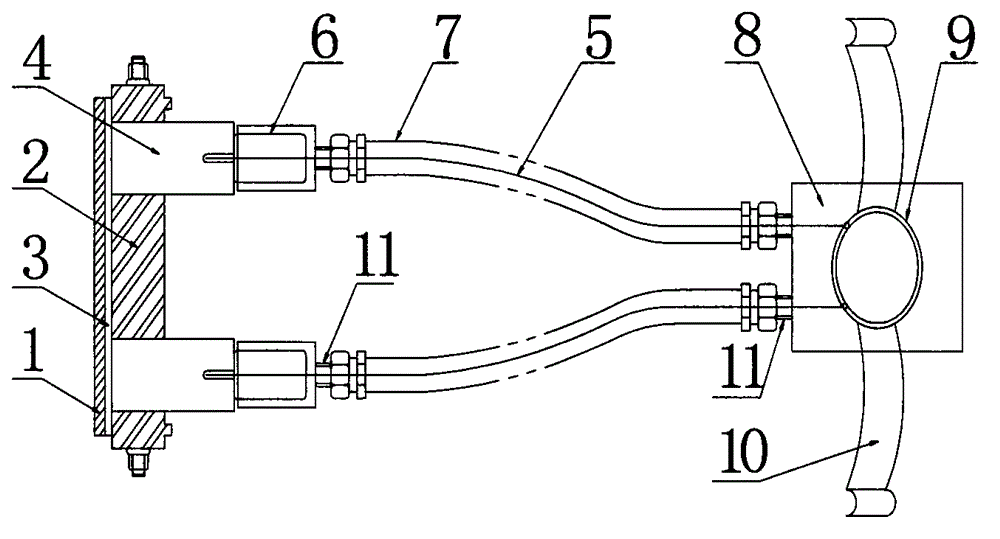

[0019] Such as figure 1 As shown, a new carbon brush structure includes a carbon brush base 1, a carbon brush tube base 2 fixed on the carbon brush base 1, and a carbon brush body 4 installed in the carbon brush tube base 2. The carbon brush tube The seat 2 is dumbbell-shaped, and a number of carbon brush tubes corresponding to the size and shape of the carbon brush body 4 are evenly distributed therein. The carbon brush tubes are all on the same plane. Elastic support 3.

[0020] Inside the carbon brush body 4 there is a lead wire 5, the wire 5 is a copper core flexible wire, the two ends of the wire 5 are respectively designed as bolts, one end is screwed into the screw hole inside the carbon brush body 4, and the other end is passed t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com