New construction method for non-stop high-speed rail

A construction method and high-speed rail technology, applied in the direction of overhead lines/cable equipment, etc., can solve problems such as the influence of the normal operation order of high-speed rail, achieve good overall strength and stability, avoid excessive force, and overcome unreliable load-bearing effects.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] A new non-stop high-speed railway construction method, which is realized by the following steps:

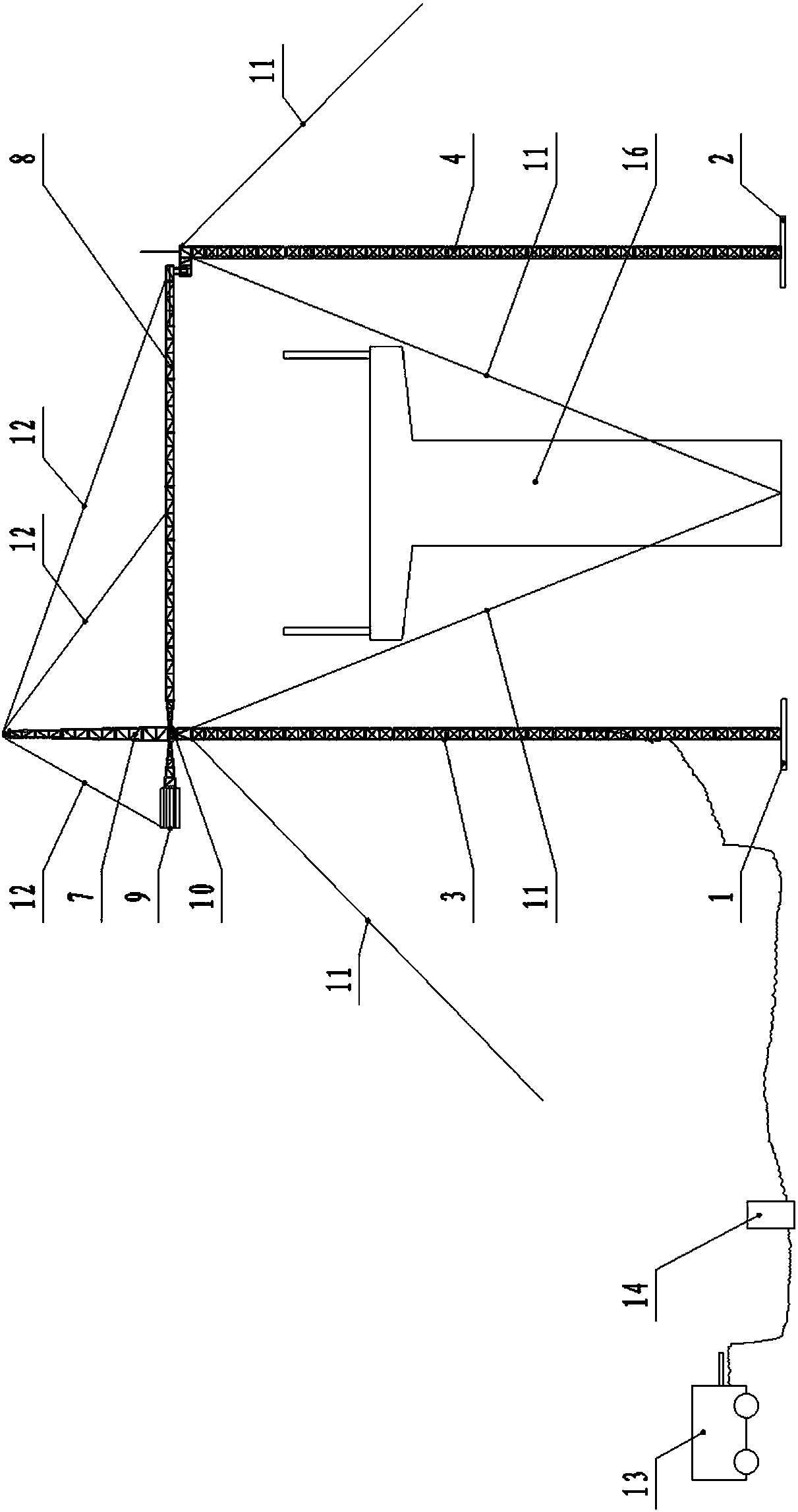

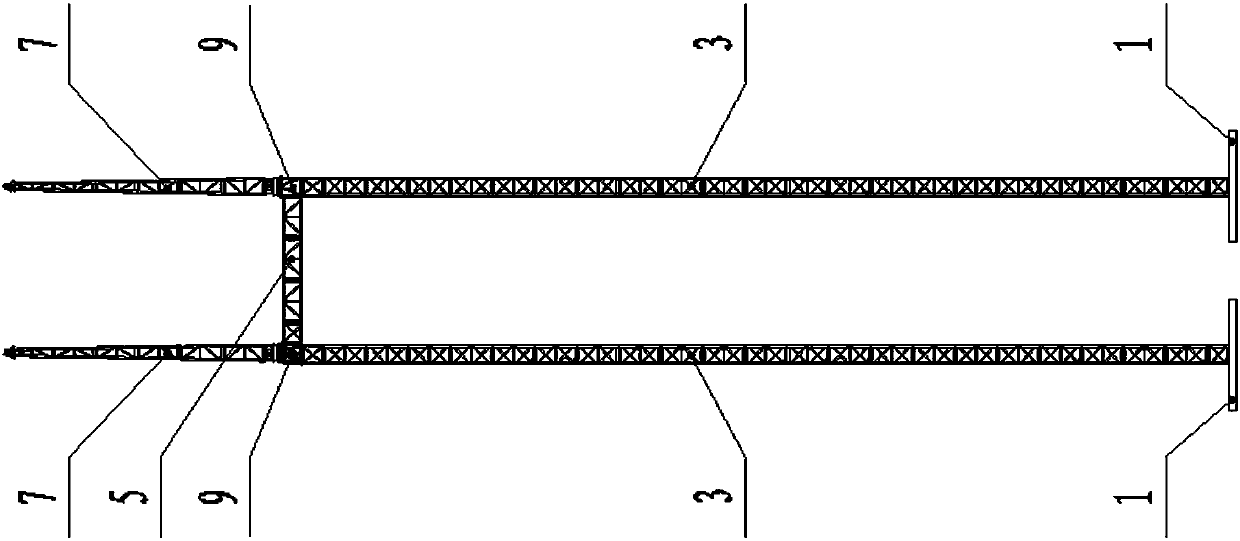

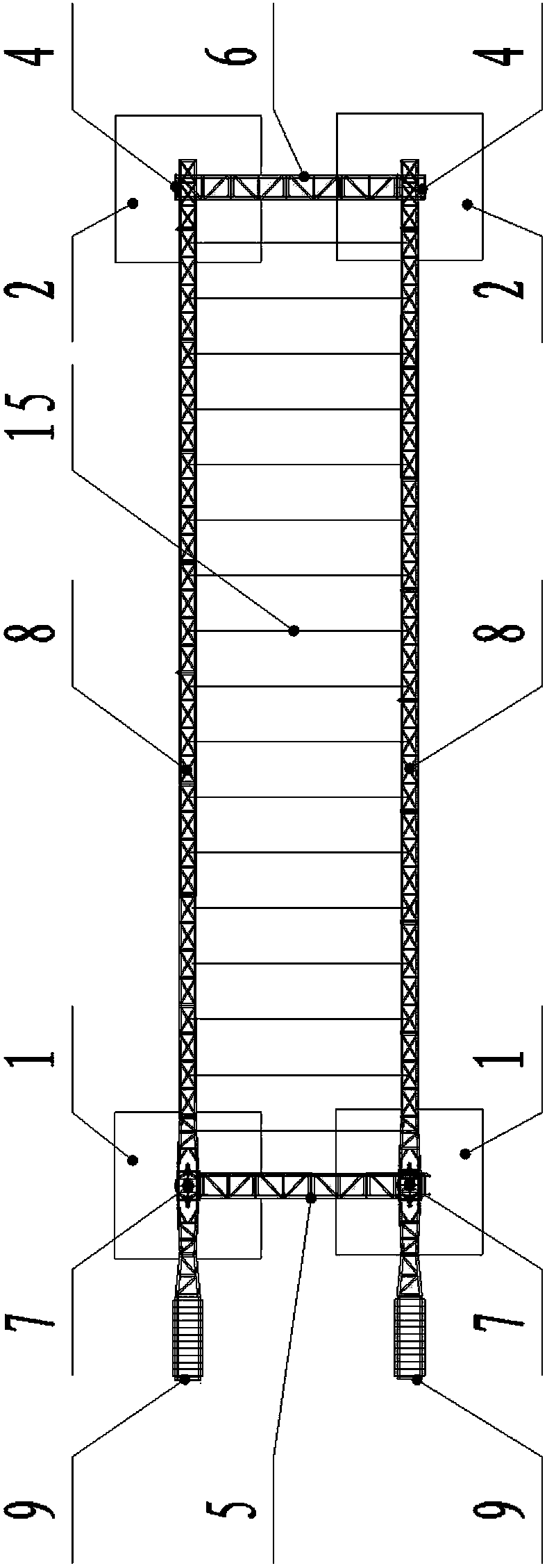

[0016] Step a. According to the high-speed rail skylight point period stipulated by the railway department, set up the spanning construction equipment within the range specified on both sides of the high-speed rail in advance; the spanning construction equipment includes the main base 1, the auxiliary base 2, the main column 3, the auxiliary column 4, The main cross-beam load-bearing beam 5, the auxiliary cross-beam load-bearing beam 6, the mast 7, the horizontal rotating arm 8, the balance beam 9, and the rotating mechanism 10; wherein, the number of the main base 1 is two; the two main bases 1 are fixed On the ground on one side of the high-speed rail; the number of sub-bases 2 is two; the two sub-bases 2 are fixed on the ground on the other side of the high-speed rail; the number of main columns 3 is two; the two main columns 3 are respectively fixed vertically On the t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com