Method for preparing exterior wall decorating plate from combustible refuse

A decorative board and garbage technology, which is applied in the field of preparing exterior wall decorative boards, can solve the problems of troublesome installation and disassembly, complicated production process and high production cost, and achieves the effects of low production cost, improved bending resistance and low production cost.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

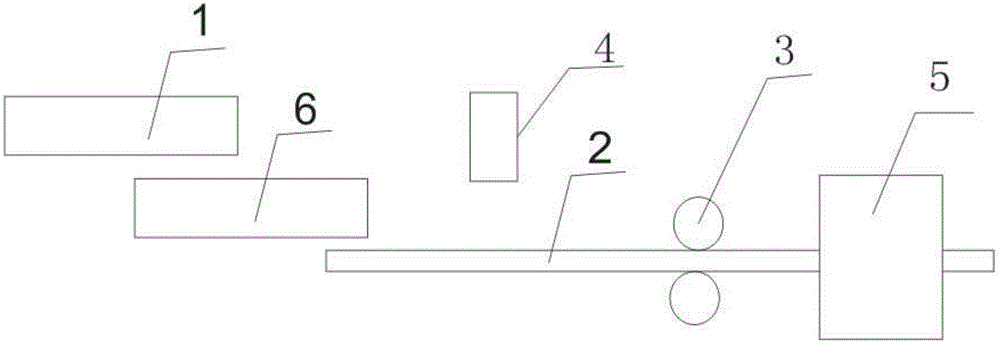

[0021] The production system of the present invention such as figure 1 As shown: the production system is composed of a grinding machine 1, a belt conveyor 2, two relatively rotating rollers 3, a cement spraying machine 4, a drying room 5, a mixer 6 and other components. The structures of rubbing mill 1, belt conveyor 2, two relatively rotating rollers 3, cement spraying machine 4, drying room 5 and mixer 6 are all prior art, and will not be repeated here.

[0022] The mixer 6 is located below the discharge port of the rubbing mill 1, the discharge port of the mixer 6 is located above the starting end of the belt conveyor 2, and the rear portion of the conveyor belt of the belt conveyor 2 passes through two rollers 3, the gap between the two rollers 3 can be adjusted. By adjusting the gap between the rollers 3, the thickness of the decorative wallboard can be adjusted. The cement shotcrete machine 4 is located above the belt conveyor 2 in front of the two relatively rotating...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com