Synchronous reluctance motor rotor and synchronous reluctance motor

A technology for synchronous reluctance motors and rotors, applied in the direction of magnetic circuit rotating parts, magnetic circuits, electrical components, etc., can solve the problems of performance degradation, motor salient pole difference reduction, etc., to improve magnetic flux leakage, increase motor output, and improve The effect of motor performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The present invention is described below based on examples, but the present invention is not limited to these examples. In the following detailed description of the invention, some specific details are set forth in detail. The present invention can be fully understood by those skilled in the art without the description of these detailed parts. To avoid obscuring the essence of the present invention, well-known methods, procedures, procedures, and components have not been described in detail.

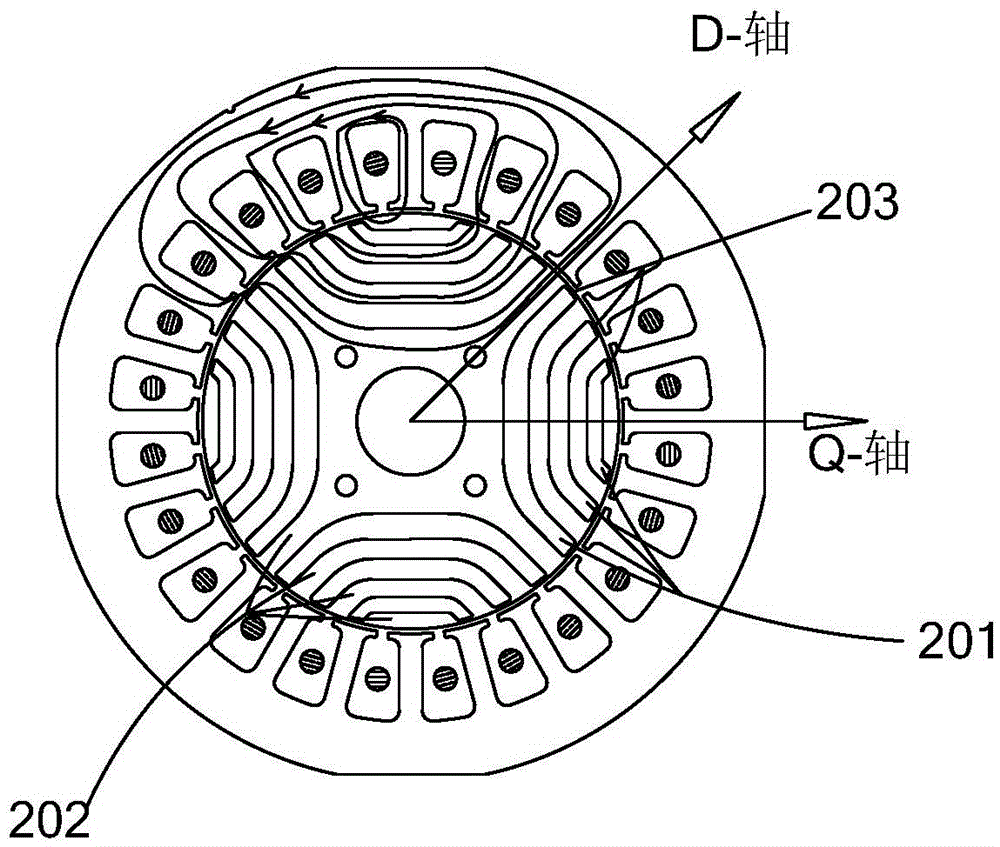

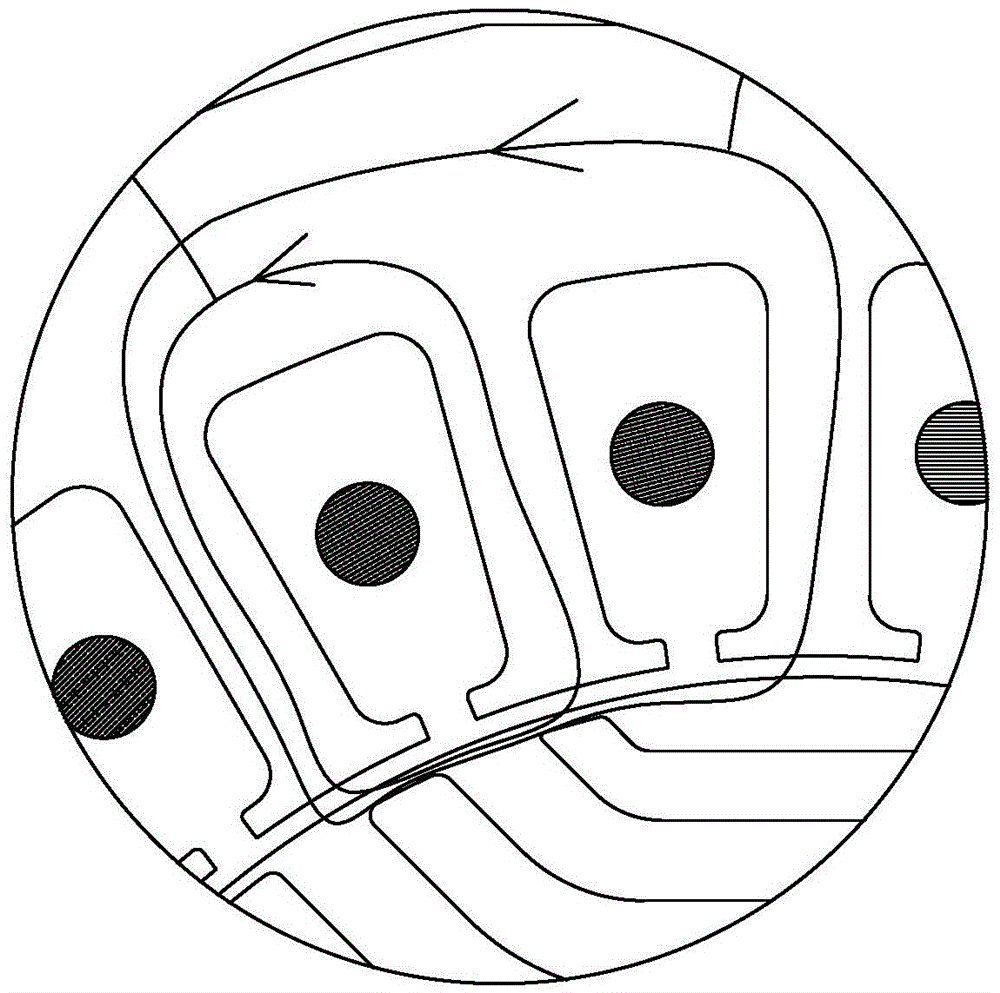

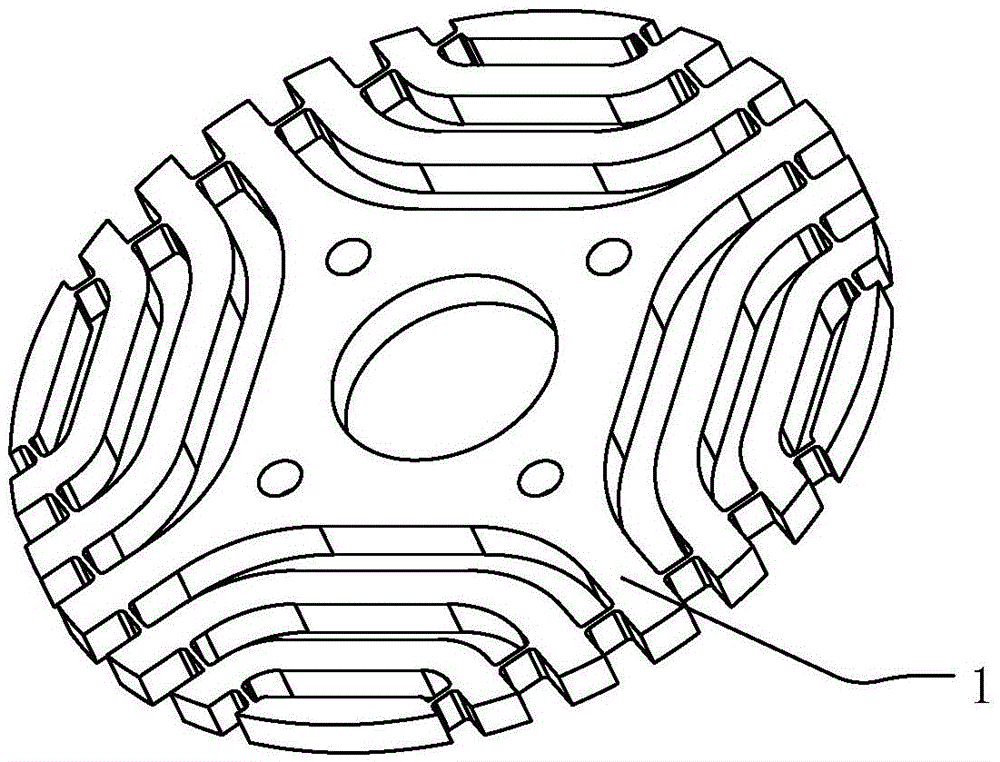

[0031] The following combination Figure 3-6 The rotor structure of the synchronous reluctance motor in the first embodiment of the present invention is described in detail, as Figure 5 As shown in , the rotor core 1 is included, and the rotor core 1 includes a plurality of flux barrier groups 11 . Each flux barrier group 11 includes at least two flux barriers arranged at intervals in the radial direction of the rotor core 1, a magnetic conduction channel is provided between a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com