Nitrile rubber composition

A technology of nitrile rubber and composition, applied in mechanical equipment, engine components, engine sealing and other directions, can solve the problems of large rubber volume change rate and low torque, and achieve the effect of suppressing the volume change rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

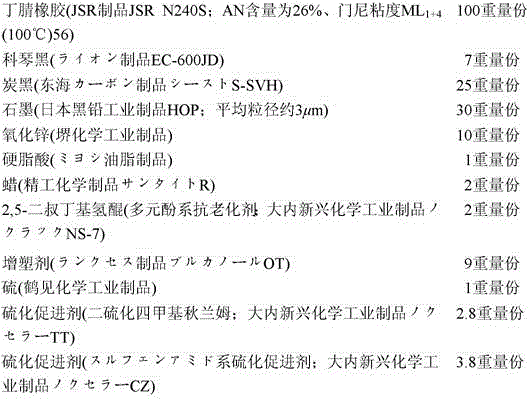

[0033] [Mixed Example I]

[0034]

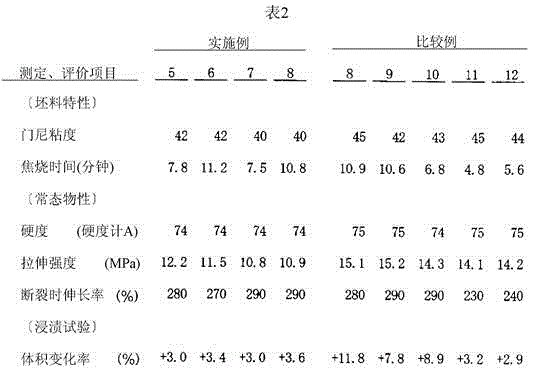

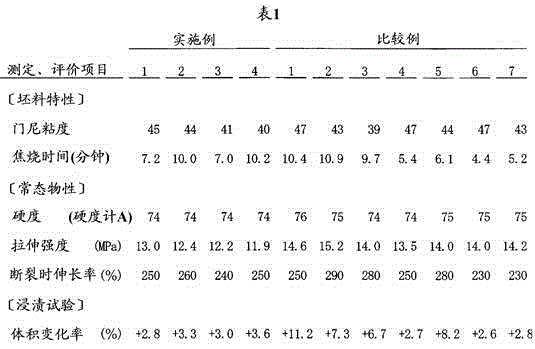

[0035] After kneading the above mixed components with a kneader and an open roll, and measuring the raw material properties (Mooney viscosity, scorch time), the kneaded product was subjected to press vulcanization at 170°C for 10 minutes and open at 150°C for 30 minutes. Formula vulcanization, produced 250 × 120 × 2mm and 50 × 20 × 0.2mm test pieces. Using the obtained test pieces, measurements of normal physical properties and immersion tests were performed.

[0036] Billet properties:

[0037] Based on JISK6300-1:2001 (Mooney test) corresponding to ASTMD1646;

[0038] Measure the minimum Mooney viscosity and scorch time T5 at 125°C;

[0039] Considering the stability of the billet and the vulcanization formability, the scorch time is preferably more than 6 minutes;

[0040] Normal physical properties:

[0041] Based on JISK6253-3:1997 corresponding to ASTMD2240 (hardness; durometer A instantaneous)

[0042] Based on JIS KK6251:2010 ...

Embodiment 2

[0053] In Example 1, the amount of 2,5-di-t-butylhydroquinone was changed to 1 part by weight and used.

Embodiment 3

[0055] In Example 1, an equivalent amount (2 parts by weight) of 2,5-di-tert-amylhydroquinone (polyphenol-based anti-aging agent; Ouchi Shinko Chemical Co., Ltd. Nocrack DAH) was used instead of 2,5-di-tert-amylhydroquinone. Butylhydroquinone.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com