Nitrile rubber composition

A technology of nitrile-butadiene rubber and composition, applied in the field of nitrile-butadiene rubber composition, can solve the problems of low torque, large rubber volume change rate, etc., and achieve the effect of suppressing the volume change rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

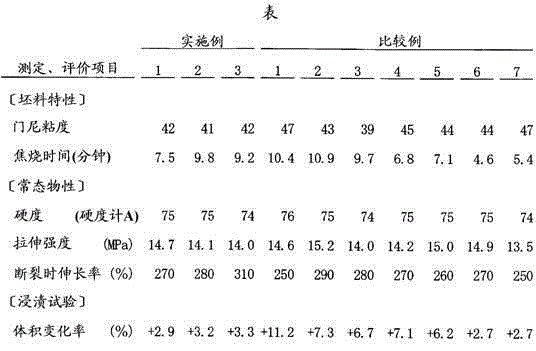

Examples

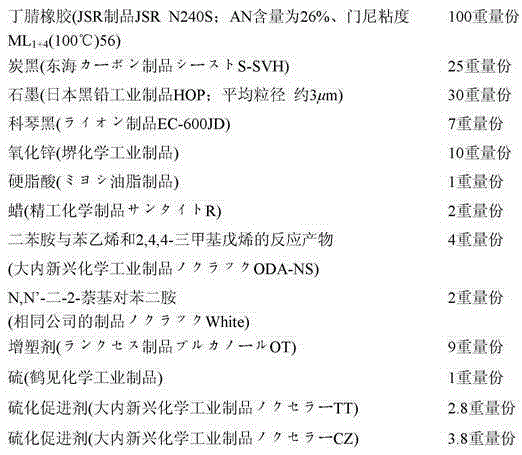

Embodiment 1

[0030]

[0031] After kneading the above mixed components using a kneader and an open roll, and measuring the raw material properties (Mooney viscosity, scorch time), the kneaded product was subjected to press vulcanization at 170°C for 10 minutes and open curing at 150°C for 30 minutes. Formula vulcanization, produced 250 × 120 × 2mm and 50 × 20 × 0.2mm test pieces. Using the obtained test pieces, measurements of normal physical properties and immersion tests were performed.

[0032] Billet properties:

[0033] Based on JISK6300-1:2001 (Mooney test) corresponding to ISO289-1:1994 and ISO289-2:1994;

[0034] Measure the minimum Mooney viscosity and scorch time T5 at 125°C;

[0035] From the perspective of the stability of the billet and the vulcanization formability, the scorch time is preferably more than 6 minutes;

[0036] Normal physical properties:

[0037] Based on JISK6253:1997 corresponding to ISO7619:2004 (hardness; durometer A instantaneous);

[0038] Based on ...

Embodiment 2

[0049] In Example 1, the amount of N,N'-di-2-naphthyl-p-phenylenediamine was changed to 1 part by weight and used.

Embodiment 3

[0051] In Example 1, instead of N,N'-di-2-naphthyl-p-phenylenediamine, 1 part by weight of dilauryl thiodipropionate (Nokrack 400 manufactured by Ouchi Shinko Chemical Co., Ltd.) was used.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com