A special infusion needle

An infusion needle and steel needle technology, which is applied in the field of special infusion needles, can solve the problems of harm, the special infusion set for preventing needle sticks cannot be located in different parts, and the needles are easily broken, so as to reduce broken needles and damage to the needle tip, reduce nosocomial infections, and reduce effect of microorganisms

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

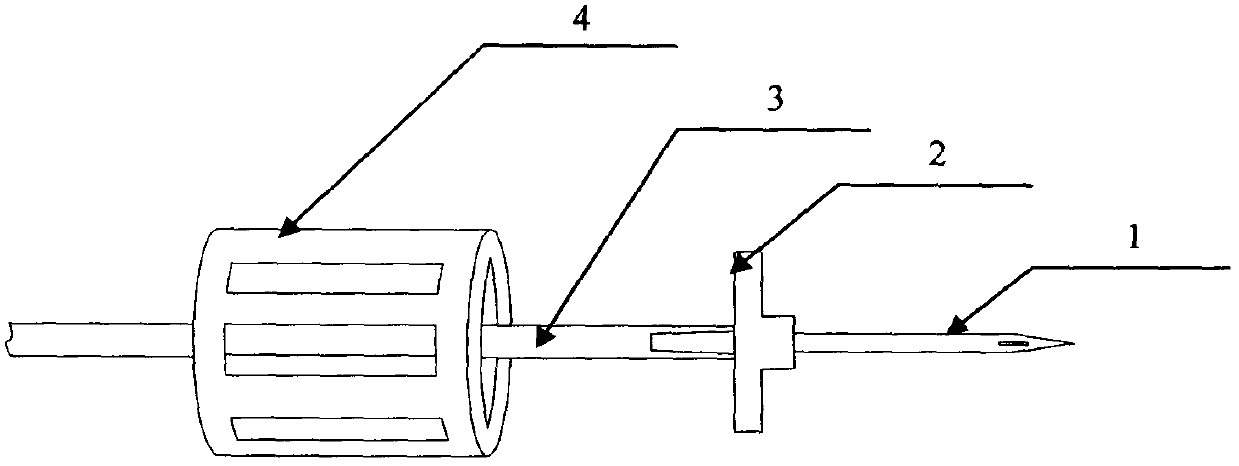

[0035] Embodiment one: see attached figure 1 Shown:

[0036] A special infusion needle, comprising a short side hole steel needle 1, a steel needle holder 2, and an infusion catheter 3 connected to the rear end of the steel needle holder 2, and the special infusion needle is covered with a protective cover that can accommodate a fixed piercing connector. Cover 4, this example is a protective cover 4 with multiple pores on the side wall. The axis of the protective sheath 4 can be far away from or close to the axis of the steel needle holder 2 .

[0037] In use, after the side-hole steel needle 1 is connected to the puncture-type connector, the protective cover 4 is inserted into the puncture-type connector for fixation, and can be fixed with adhesive tape or its own elasticity, so as to realize the suspended connection. In order to prevent needle sticks, the protective cover 4 can be set or pushed forward to completely cover the steel needle 1 before use and then connected. ...

Embodiment 2

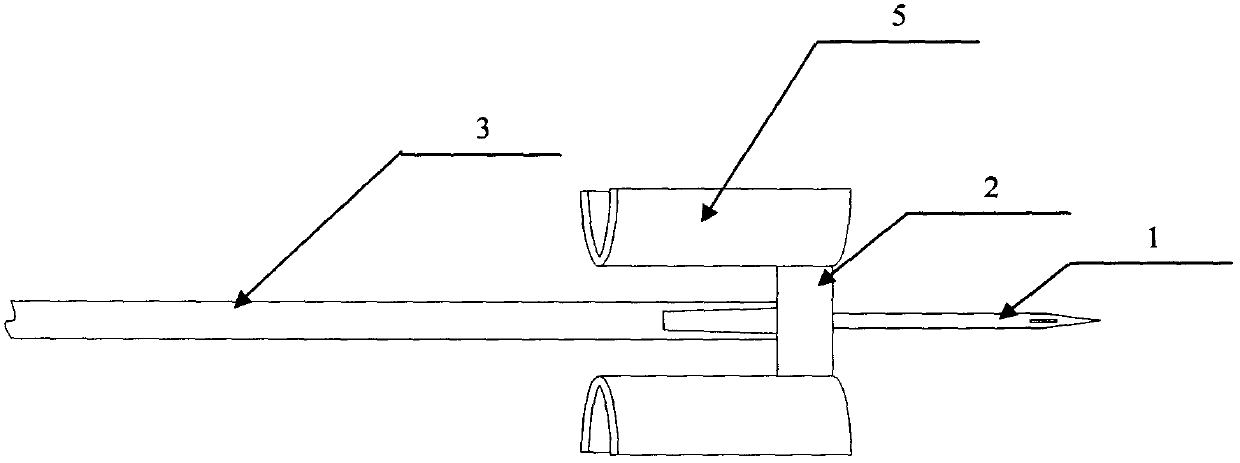

[0038] Embodiment two: see attached figure 2 Shown:

[0039] A special infusion needle, comprising a steel needle 1 with a conical needle point, an infusion hole located on the side wall of the needle tube behind the rear edge of the conical needle point, a steel needle holder 2 and an infusion catheter connected to the rear end of the steel needle holder 2 3. The infusion needle is fixed with a fixed protection device that can rotate and cover the surface of the piercing connector. In this example, it is two opposite tile-shaped plates 5 .

[0040] In use, after the infusion needle is connected to the puncture-type connector, the fixing protection device is covered on the surface of the puncture-type connector for fixation. The fixation here can be fixed with adhesive tape or its own rope or buckle to realize the suspended connection. The steel needle 1 with the conical needle tip is punctured at a point where the infusion end face of the puncture-type connector is connecte...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com