Concrete mixer truck

A technology of mixer truck and concrete, applied in the field of construction vehicles, can solve the problems of the driver, the high fatality rate of the car accident, the serious car accident, etc., and achieve the effect of reducing the probability of car accident, good safety, and reducing the risk.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

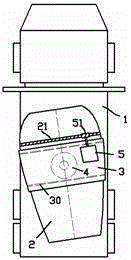

[0013] Embodiments of the present invention are as figure 1 As shown, the concrete transport mixer truck includes a main body 1 and a rotating drum 2; the rotating drum 2 is placed in a ring sleeve 3, and cooperates with the ring sleeve 3 through a ring groove 30, so that the rotating drum 2 can be placed in the ring sleeve 3 rotates around the axis of the rotating drum 2 itself; the ring sleeve 3 is fixed on a horizontal turntable 4, the horizontal turntable 4 is set on the body 1 of the vehicle body, and can rotate around its own axis, and the horizontal turntable 4 has a rotational pre-tightening force and, the axis of the horizontal turntable 4 intersects the axis of the rotating drum 2, and its intersection is between the center of gravity of the rotating drum 2 and the end of the rotating drum near the headstock, that is, the rotating drum 2 is on the axis of the horizontal rotating disc 4 The quality of the two sides is not equal.

[0014] In the static state of the bo...

Embodiment 2

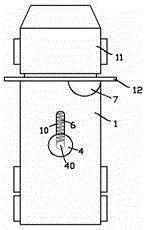

[0018] figure 2 Shown is the second embodiment of the present invention, considering the clarity of the drawing, figure 2 has been omitted figure 1 The drum 2, the ring sleeve 3, and the driving mechanism 5; in fact, the drum 2, the ring sleeve 3, and the driving mechanism 5 in the second embodiment are the same as those in the first embodiment; the difference between the second embodiment and the first embodiment is , the axis of the horizontal turntable 4 has a rotating shaft 40 that can rotate relative to the horizontal turntable, and the rotating shaft 40 is constrained in the chute 10 on the body body; the chute 10 is opened in the center of the body body 1 On the cut surface; the support spring 6 extending along the chute is also provided in the chute 10 to provide cushioning and restoring force for the sliding of the rotating shaft 40 in the chute 10; A vertical baffle 12; the vertical baffle 12 is provided with a hemispherical recoil block 7; the recoil block 7 is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com