Luminous plate and manufacture method thereof

A luminous board and luminous technology, applied in the field of luminous boards, can solve the problems of weak light emission and short luminous time of luminous boards, and achieve the effect of saving power

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

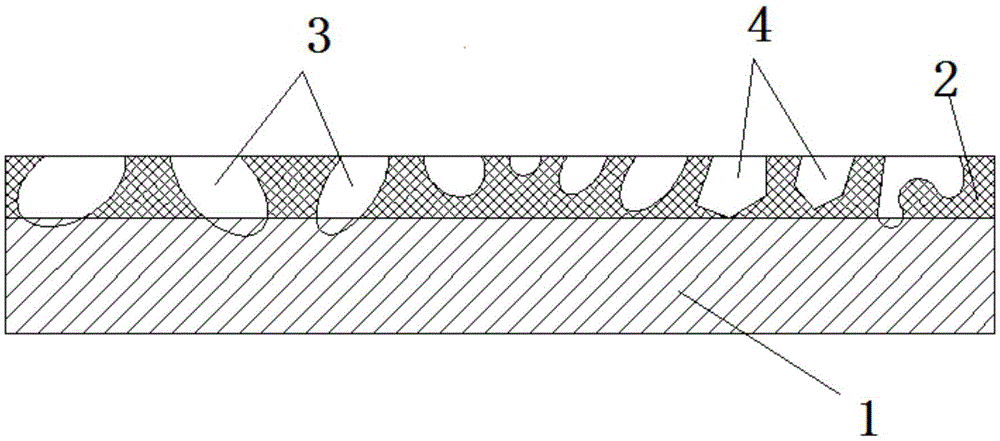

[0018] A luminous panel, such as figure 1 As shown, the luminous board is composed of a cement layer 1 and a luminous material layer 2 , and the luminous material layer is inlaid with luminous material particles 3 and colored stones 4 . The luminous substance particles are SrGa 2 o 4 :Eu,PbWO 4 , and Sr 5 (PO 4 )Cl:Eu is prepared according to the mass ratio of 1:1:1. The cement slurry adopts fast-hardening sulfoaluminate cement, because it belongs to the early-strength type, the setting time is fast, and the early strength is basically finalized, which can greatly save the construction period.

[0019] A preparation method of the above-mentioned luminous board, first prepare cement slurry, and add luminous material particles and colored stones into the slurry and stir evenly, then pour it into a board, dry and harden to reach a strength above C30, polish the surface smooth and Expose the luminescent substance.

[0020] The prepared luminous board can emit light for 36 h...

Embodiment 2

[0022] A luminous panel, such as figure 1 As shown, the luminous board is composed of a cement layer 1 and a luminous material layer 2 , and the luminous material layer 2 is inlaid with luminous material particles 3 and colored stones 4 . The luminous substance particles are M 2 Si 5 N 8 . The cement slurry adopts fast-hardening sulfoaluminate cement, because it belongs to the early-strength type, the setting time is fast, and the early strength is basically finalized, which can greatly save the construction period.

[0023] A preparation method of the above-mentioned luminous board is to shoot luminous material particles and colored stones on the surface of the cement board that has not yet solidified, and pour cement slurry between the particles for leveling, and the board after leveling is dried and hardened to a strength above C30 Finally, the leveled surface is sanded down to reveal the luminescent substance.

[0024] The prepared luminous board can emit light for 36...

Embodiment 3

[0026] A luminous panel, such as figure 1 As shown, the luminous board is composed of a cement layer 1 and a luminous material layer 2 , and the luminous material layer 2 is inlaid with luminous material particles 3 and colored stones 4 . The luminous substance particles are PbWO 4 ,SrS:Eu,(Y,Gd) 3 Ga 5 o 12 :Ce is mixed according to the mass ratio of 1:1:1. The cement slurry adopts fast-hardening sulfoaluminate cement, because it belongs to the early-strength type, the setting time is fast, and the early strength is basically finalized, which can greatly save the construction period.

[0027] A preparation method of the above-mentioned luminous board is to shoot luminous material particles and colored stones on the surface of the cement board that has not yet solidified, and pour cement slurry between the particles for leveling, and the board after leveling is dried and hardened to a strength above C30 Finally, the leveled surface is sanded down to reveal the luminescent...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com