A composite pipe inner support component

A technology for supporting components and composite pipes, applied in the direction of pipe elements, pipes/pipe joints/fittings, packaging, etc., to simplify the installation and maintenance process, meet the limit requirements, and meet the limit and structural strength requirements.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] The present invention is described in detail below in conjunction with accompanying drawing and embodiment:

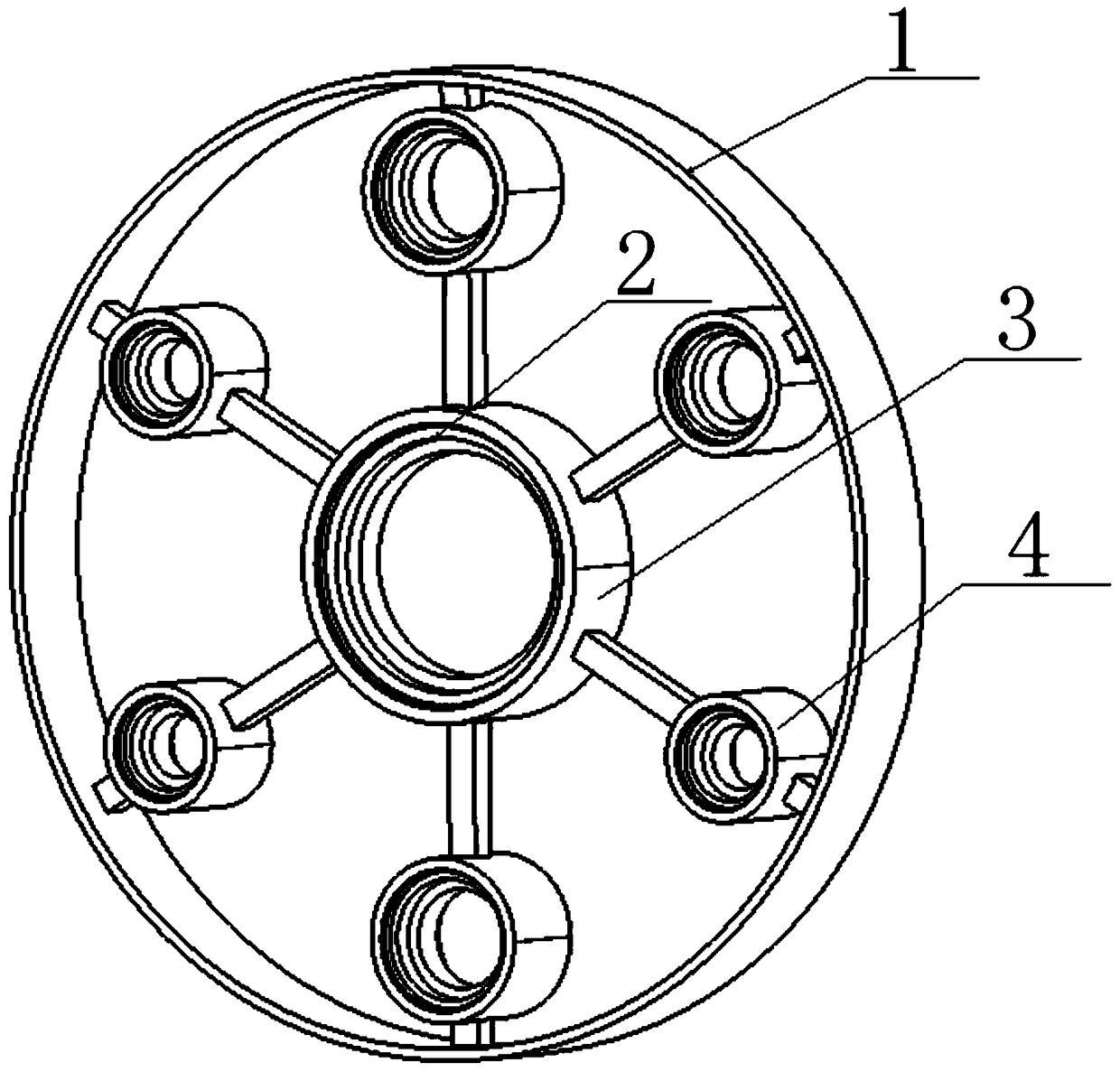

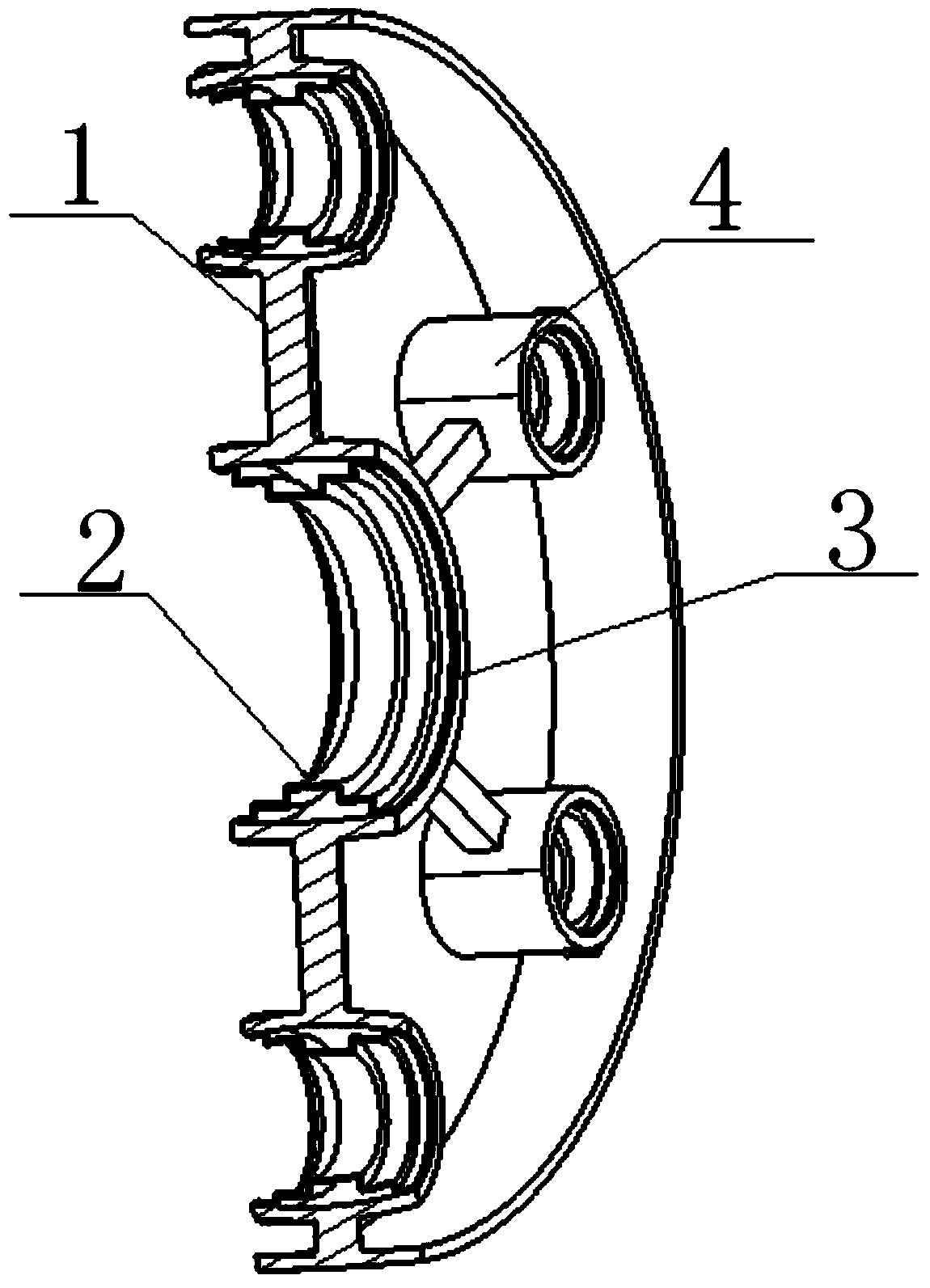

[0012] Such as figure 1 and 2 As shown, a composite pipeline internal support assembly includes a support body 1, a plurality of sleeves 4 are radially connected inside the support body 1, and the sleeves 4 are connected to the central sleeve 3 through connectors, wherein the central sleeve 3 and The bushings 4 are all stepped annular structures 2 in the shape of a "convex".

[0013] The material is stainless steel (304 or 316) in the present invention, but it is not limited to this in use. The size and size of the support body must match the pipe diameter of the composite piping system, and the thickness must meet the conditions that no inversion or deviation will occur, and the width of the contact surface can be adjusted reasonably according to requirements; the application of this component, the support The outer ring of the main body is in contact with t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com