Elevator balance coefficient detection device and method

A technology of balance coefficient and detection device, applied in the directions of transportation, packaging, elevators, etc., can solve the problems of cumbersome detection instruments, danger, time-consuming and labor-intensive, etc., and achieve the effect of reducing the calculation cost and making the test process convenient and quick.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

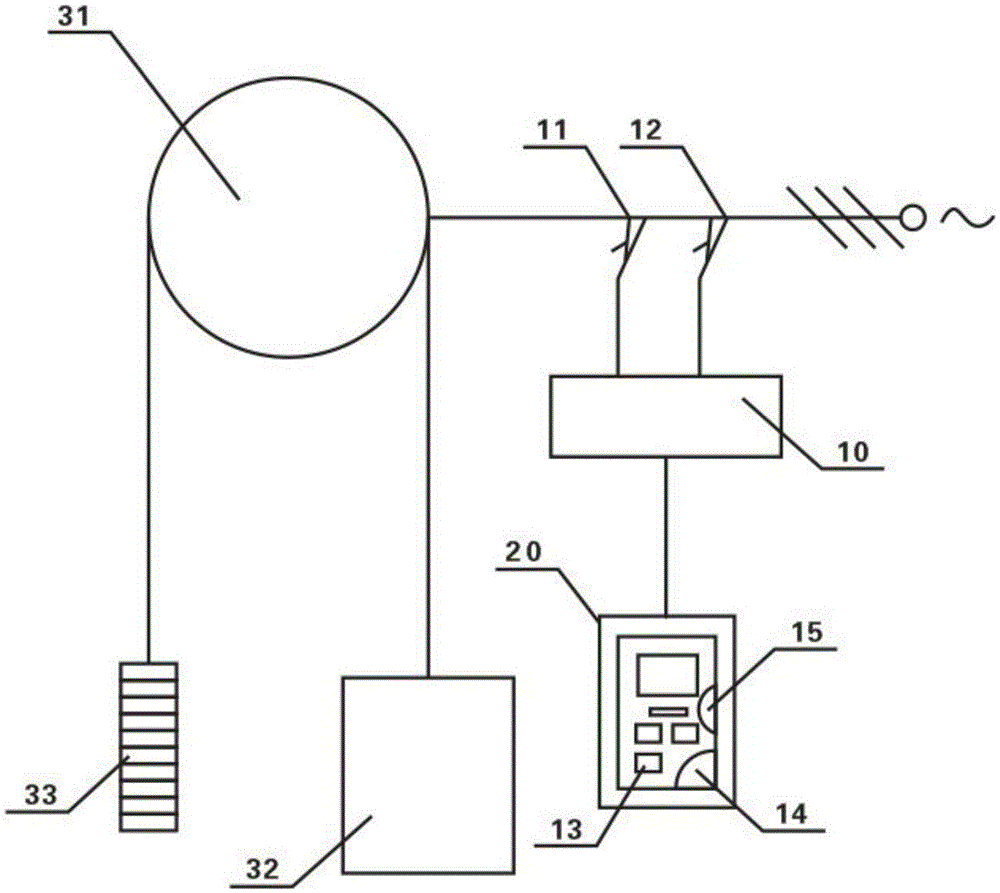

[0064] Such as figure 1 Shown, a kind of elevator balance coefficient detecting device of the present invention comprises

[0065] A power detection module 10, which is connected to the power line of the elevator traction machine 31, and is used to detect the power of the elevator traction machine 31; and

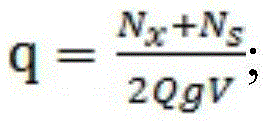

[0066] The user terminal 20 is connected to the power detection module 10, and outputs the elevator balance coefficient q according to the power of the elevator traction machine through the following formula:

[0067] q = N x + N s 2 Q g V ;

[0068] in,

[0069] q is the elevator balance coefficient;

[0070] Q is the rated load;

[0071] g is the acceleration due to gravity, preferably 9.8m / s 2 ;

[0072] N X is the no-...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com