Stable lifting and conveying type tower crane

A tower crane, stable technology, applied in the direction of cranes, etc., can solve the problem of insufficient safety, achieve the effect of improving stability, stable structure, and convenient use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

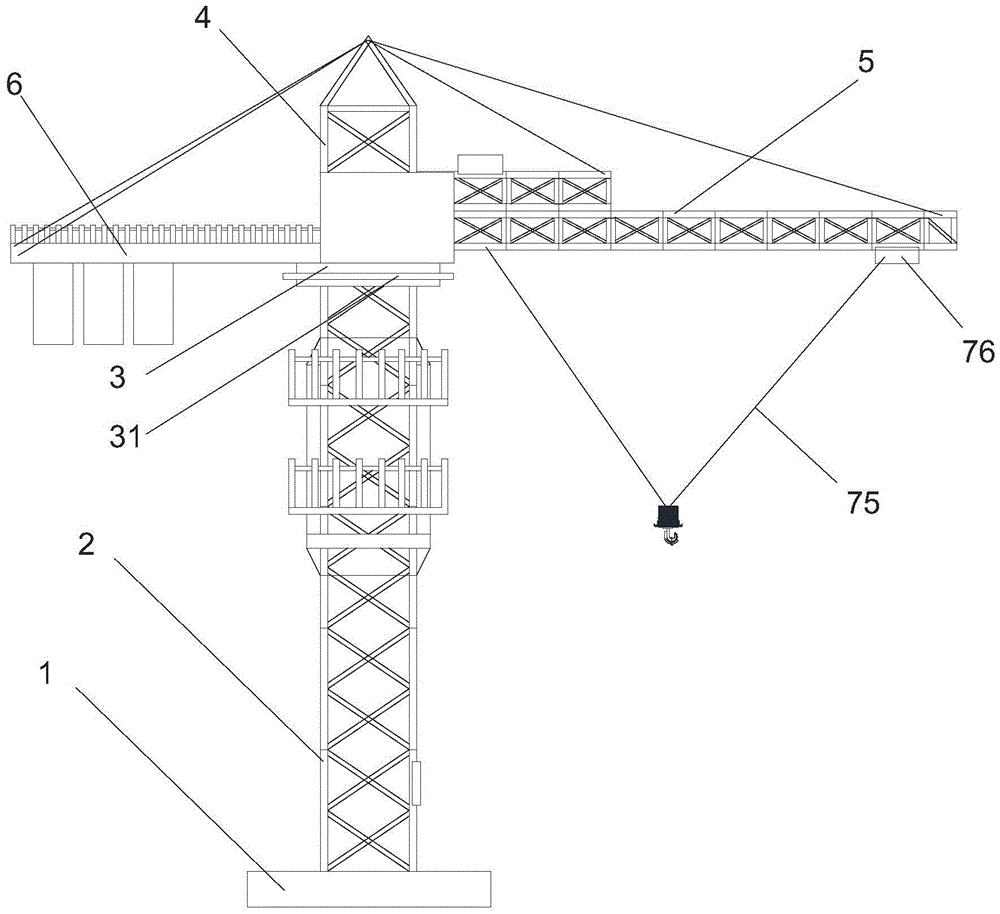

[0017] refer to figure 1 and figure 2 As shown, a kind of hoisting and stable tower crane proposed by the present invention includes a base 1, a tower body 2, a turntable 3, a tower top 4, a boom 5, a balance arm 6 and a lifting mechanism;

[0018] The tower body 2 is installed on the upper end of the base 1, the turntable 3 is installed on the upper end of the tower body 2, the tower top 4 is installed on the upper end of the turntable 3, the lifting arm 5 and the balance arm 6 are installed on the tower top 4 and are located at two opposite sides of the tower top 4. side;

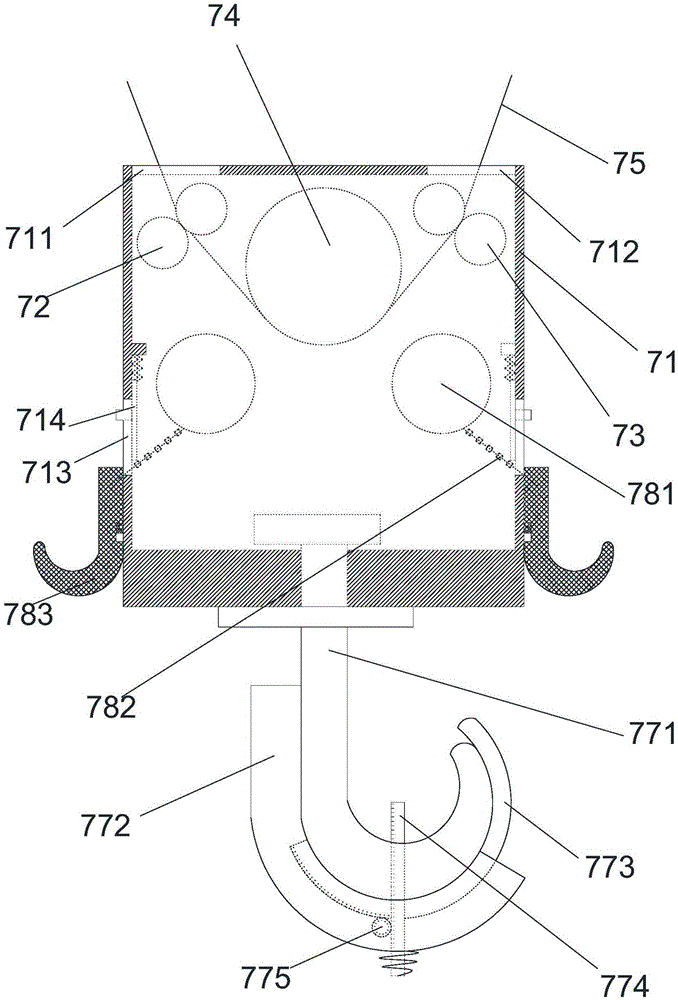

[0019] The lifting mechanism includes a wire box 71, a first positioning wheel set 72, a second positioning wheel set 73, a guide wheel 74, a traction line 75, a winding device 76, a first hanging device and two positioning devices;

[0020] Wire box 71 upper end is provided with wire inlet hole 711 and wire outlet hole 712, and first positioning wheel group 72 and second positioning wheel group 73 are...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com