Sugarcane preash pressing process

A pre-ash and process technology, which is applied in the directions of extracting juice from sugar cane, tearing sugar cane, and producing sucrose, etc., can solve the problems of incomplete reaction of organic acids, short pre-ash process, and increase of reducing sugar decomposition pigments, so as to avoid The effect of a large amount of decomposition of pigment increase

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The present invention presents many applicable inventive concepts that can be embodied in numerous specific contexts. The specific examples described in the following embodiments of the present invention are only used as illustrations of specific embodiments of the present invention, and are not intended to limit the scope of the present invention.

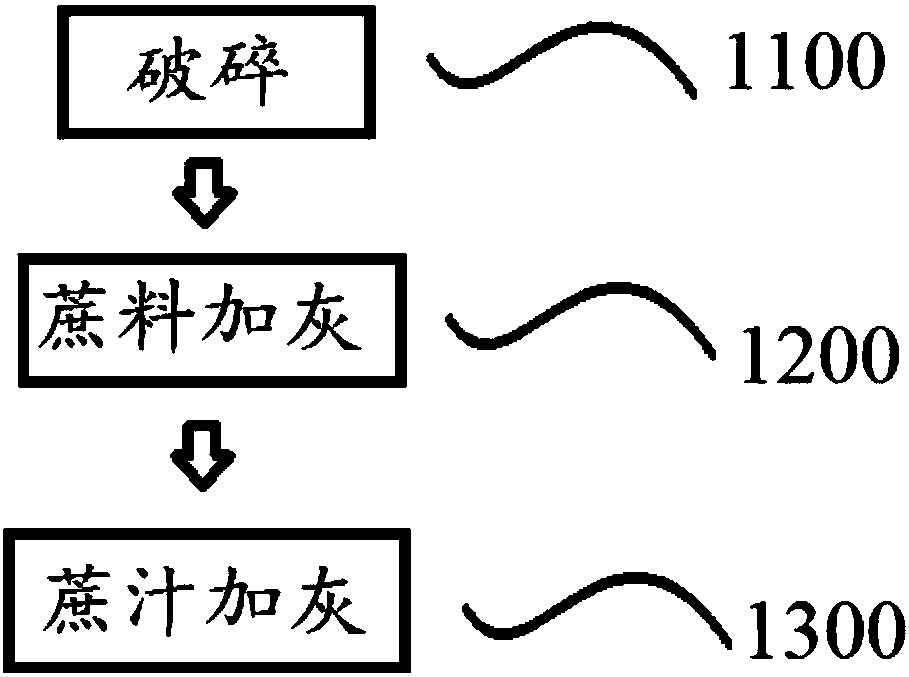

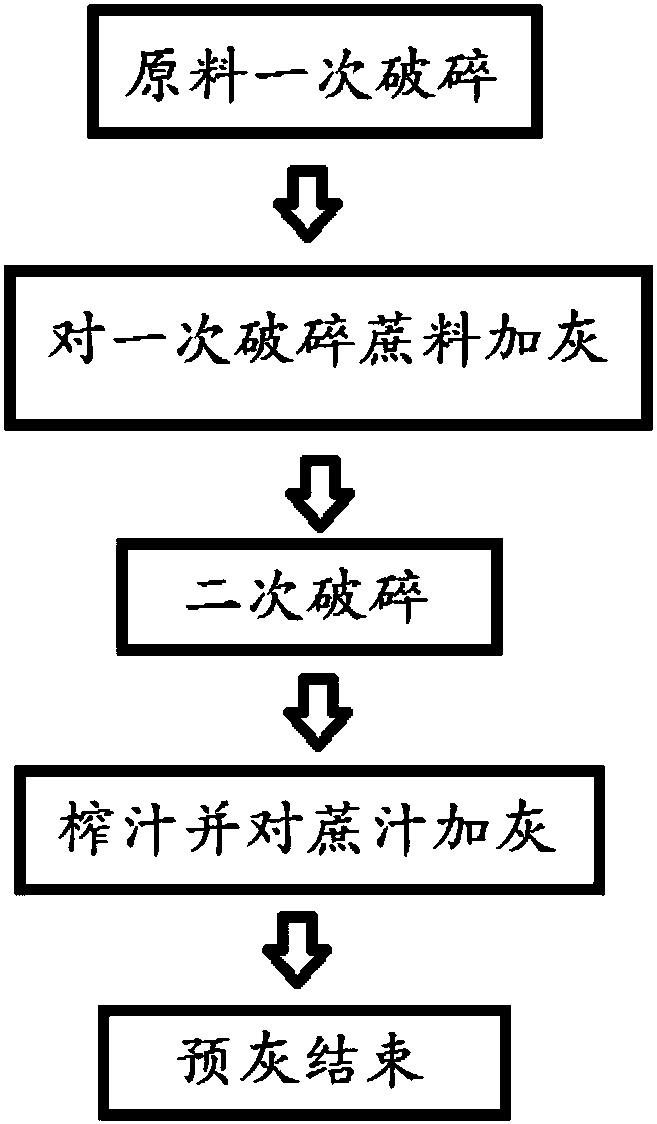

[0034] The invention provides a sugarcane preash pressing process, such as figure 1 The following steps are shown: 1100) crushing: crushing sugarcane raw materials to obtain crushed sugarcane material; 1200) adding ash to the sugarcane material: spraying lime milk into the crushed sugarcane material to adjust the pH value of the sugarcane material, and mixing evenly to obtain The crushed cane material mixed with lime milk, the amount of lime milk sprayed on the crushed cane material makes the PH of the initial pressed juice of the cane material 8-8.5; The juice is produced, and milk of lime is added to the cane juice to ad...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com