A rotary joint connection device for prefabricated component braces and its use method

A technology of rotary joints and prefabricated components, applied in building construction, building material processing, construction, etc., can solve the problems of eccentric compression of diagonal braces, affecting the installation quality of prefabricated components, etc., and achieves easy operation, safe and efficient verticality, Good promotion effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

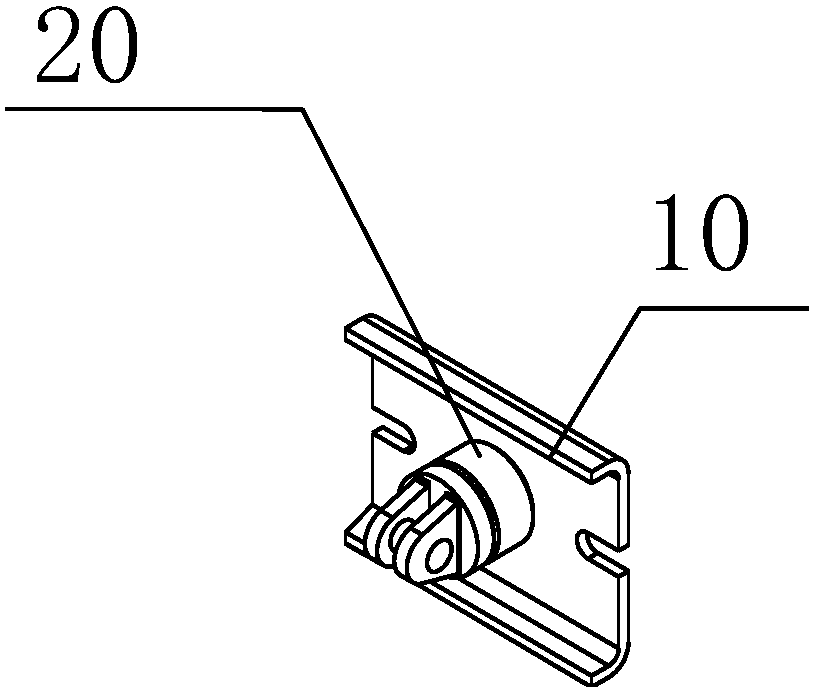

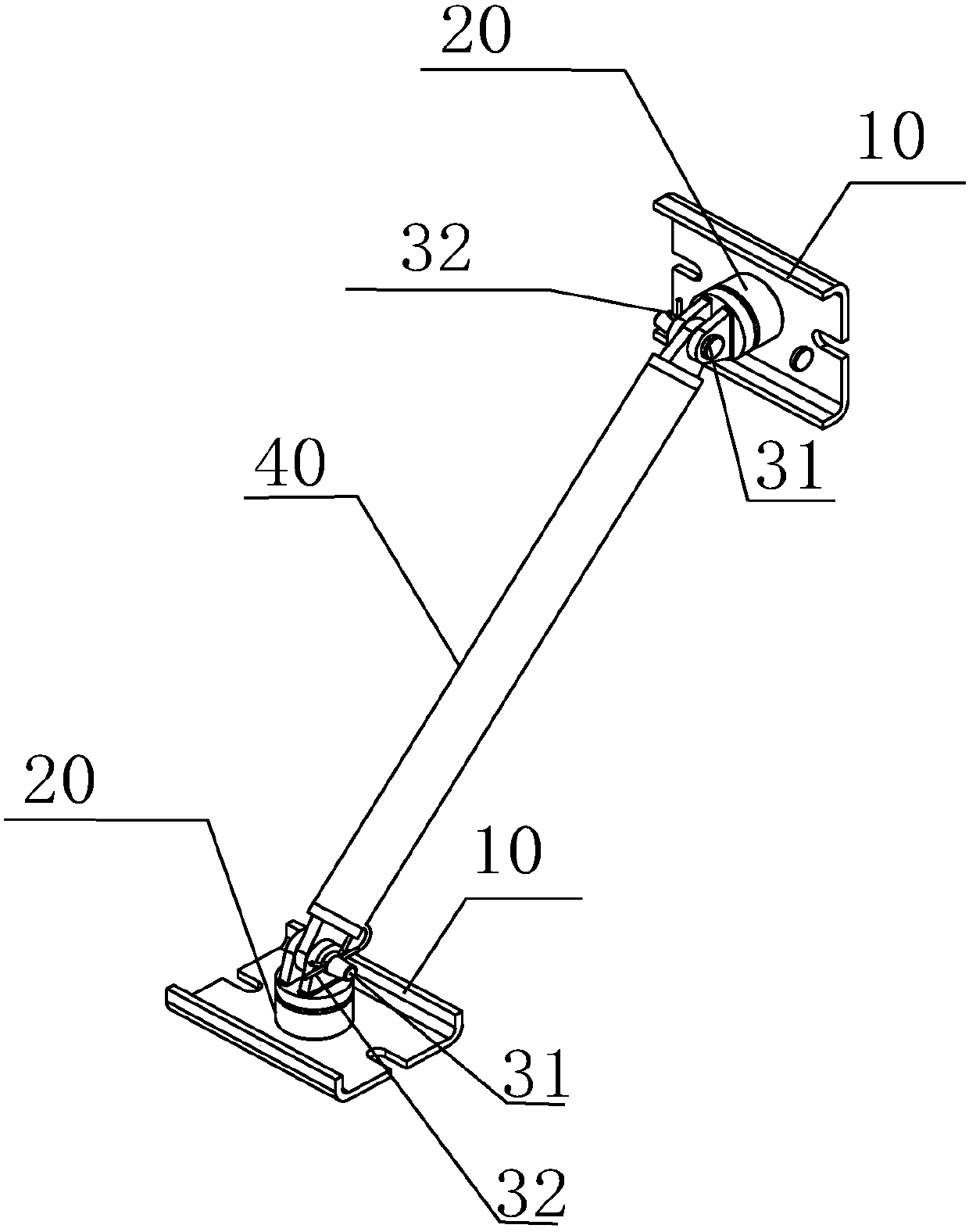

[0023] combine figure 1 and figure 2 The rotary joint connection device for prefabricated component braces of the present invention is described. The rotary joint connection device for prefabricated component braces includes embedded plates 10, 360-degree rotary joints 20 and limit members. The embedded plates 10 pass through the embedded parts respectively. (not shown) is fixedly connected with prefabricated wall components (not shown) or prefabricated floor components (not shown), and the 360-degree swivel joint 20 can be set perpendicular to the prefabricated wall components or prefabricated floor components and fixedly connected with the buried slab The end of the limiting member passing through the brace 40 is fixedly connected to the free end of the 360-degree rotatable joint 20 . The device can realize the "hinge" of the joints and avoid additional stress on the plates and supporting rods.

[0024] Specifically, in order to make the prefabricated wall components and ...

Embodiment 2

[0033] Continue to refer to the following figure 1 and figure 2 , taking the installation of a brace 40 as an example to describe in detail the method of using the swivel joint connection device for the brace of a prefabricated component according to the embodiment of the present invention.

[0034] A method for using a swivel joint connection device for a prefabricated component brace includes the following steps:

[0035] Step 1. One diagonal brace 40 is equipped with two rotary joint connection devices for prefabricated component diagonal braces, and the rotary joint connections for prefabricated component diagonal braces are respectively installed at the positions of prefabricated wall components and prefabricated floor components. device, respectively fixedly connect the two ends of the diagonal brace 40 with the connecting device at the corresponding end, so that one end of the diagonal brace 40 is fixed on the prefabricated wall component, and the other end of the dia...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com