Space curved surface type underwater sealing element and mounting method

An installation method and a technology of seals, which are applied to ship components, transportation and packaging, ships, etc., can solve the problems of water ingress into the lubricating grease chamber, reduced sealing effect, and damage to threaded holes, so as to achieve good sealing effect and ensure Force stability and overall sealing effect, good watertight effect and long-term watertight performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

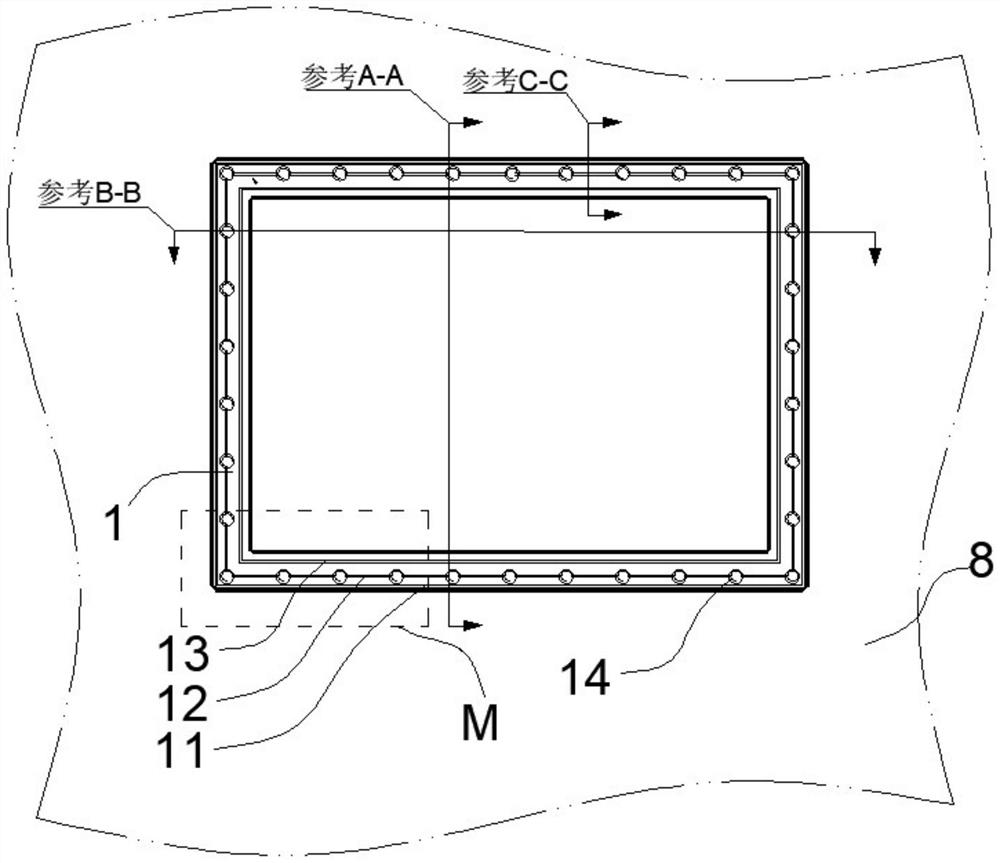

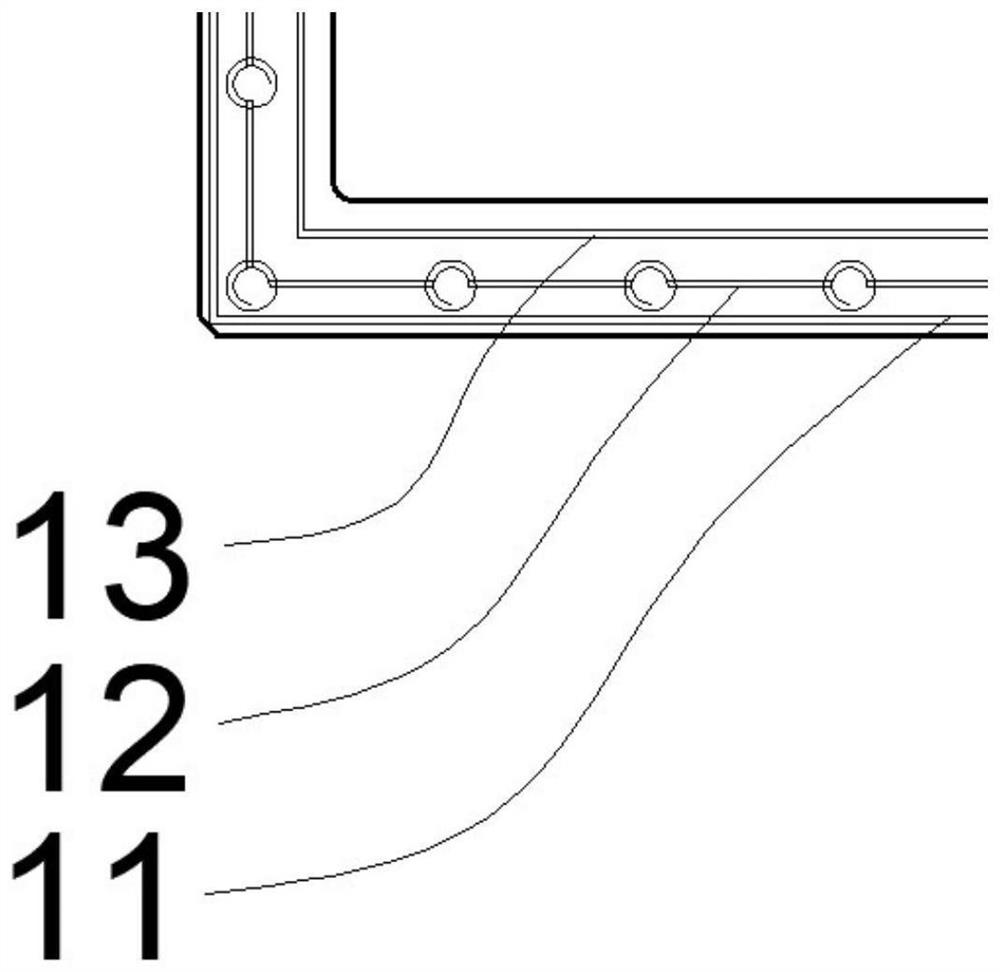

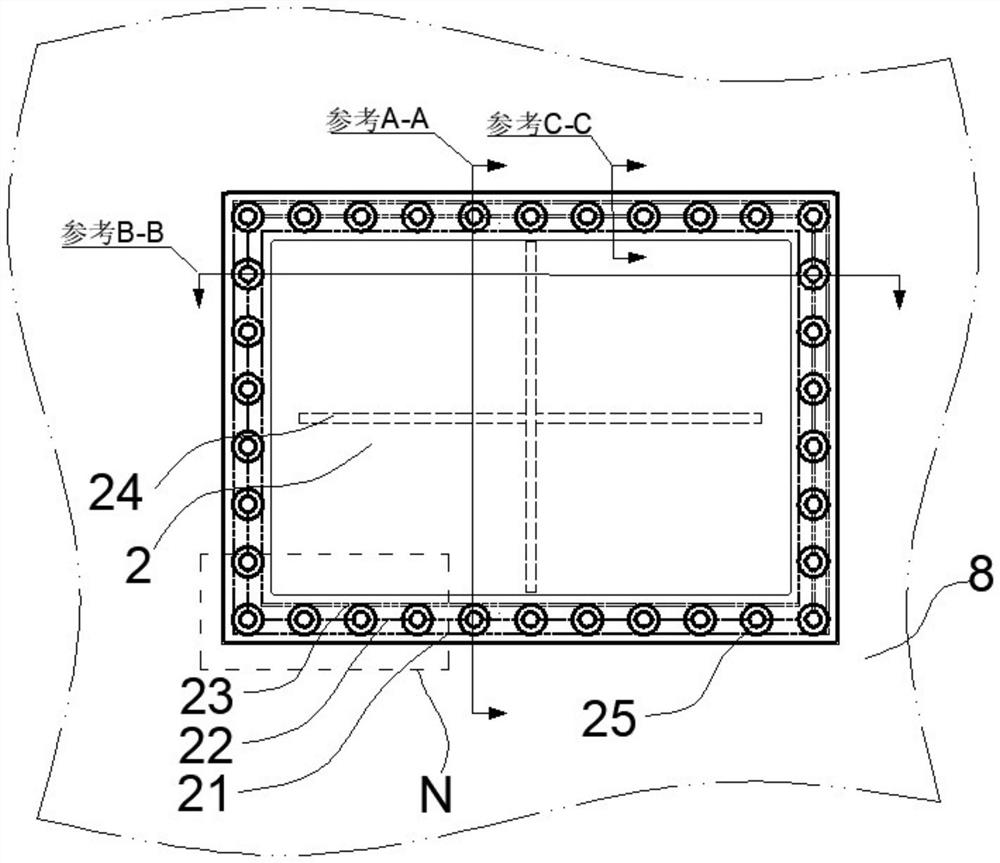

[0057] This embodiment provides a space surface type underwater seal, such as Figure 1-8As shown, the seal includes a surrounding frame 1, a sealing gasket 3 and a cover plate 2 stacked in sequence. The outer edge dimensions of the surrounding frame 1, sealing gasket 3 and cover plate 2 are the same as each other. The surrounding frame 1 and The inner edge of the sealing gasket 3 has the same size, the side of the surrounding frame 1 in contact with the sealing gasket 3 has a plurality of surrounding frame grooves nested in each other, and the area where the cover plate 2 contacts with the sealing gasket 3 There are a plurality of cover plate grooves nested in each other, and the surrounding frame grooves and the cover plate grooves are both closed rings.

[0058] Specifically, such as Figure 8 As shown, the opening edge of the grease cavity 70 is fixedly connected to one end of the cavity coaming plate 7, and the other end of the cavity coaming plate 7 is fixedly connected...

Embodiment 2

[0075] This embodiment provides an installation method of a space curved surface type underwater seal, and the installation method includes the following steps:

[0076] S1: provide a surrounding frame 1, a grease cavity 70 and a space curved workpiece 8, the opening edge of the grease cavity 70 is fixedly connected to one end of the cavity coaming plate 7, and the other end of the cavity coaming plate 7 is connected to The opening edge of the space curved surface workpiece 8 is fixedly connected, and the surrounding frame 1 is fixed on the inner side of the cavity surrounding plate 7;

[0077] S2: Assemble the sealing gasket 3 and the cover plate 2 sequentially on the surrounding frame 1, the gasket through hole 31 on the sealing gasket 3 and the cover plate through hole 25 on the The threaded hole 41 corresponds through, wherein,

[0078] The dimensions of the outer edges of the surrounding frame, the sealing gasket and the cover plate are the same as each other, the dimens...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com