Measuring method of radial flow clearance of steam turbine unit in full cylinder state

A technology of a steam turbine unit and a measurement method, which is applied in the directions of mechanical clearance measurement, mechanical measurement device, measurement device, etc., can solve the problems of small radial flow gap, small volume of high-voltage module, and steam flow excitation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] In order to describe the technical features and functions of the present invention in detail and realize them according to the content of this specification, the implementation of the present invention will be further described below in conjunction with the accompanying drawings.

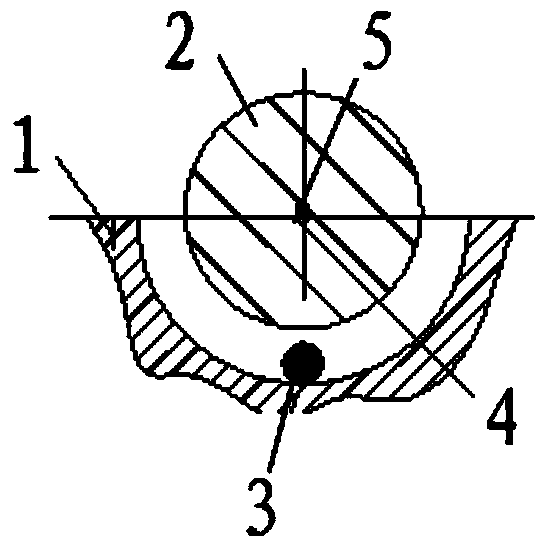

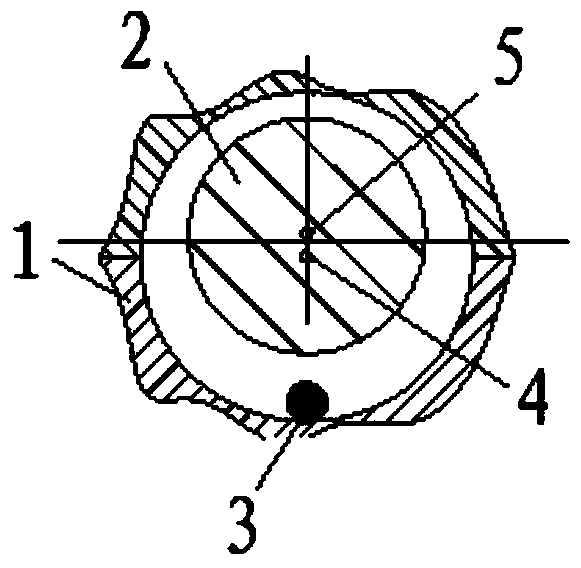

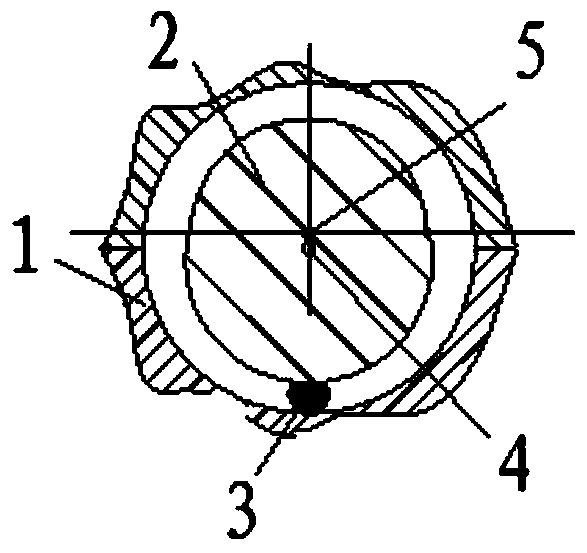

[0037] see Figure 1 to Figure 7 , which is a method for measuring the radial flow gap in the state of full solid cylinder of a steam turbine unit according to the present invention. see Image 6 , 7 , The required construction equipment for the method of the present invention includes a first support protection member 7, 2 sets of dial gauges 9, 2 sets of V-shaped blocks 10 and a mechanical jack 11. In this embodiment, the V-shaped block 10 and the mechanical jack 11 form a rotor jacking device, and the first support and protection member 7 uses three sheets of lead paper with a thickness of 0.5 mm. in, Figure 1-5 Among them, the code 1 is the lower half of the stator, the code 4 is the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com